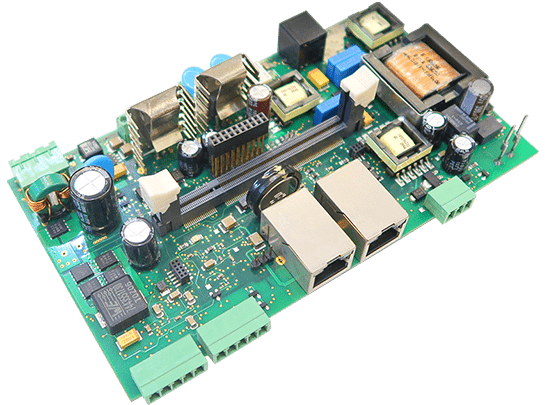

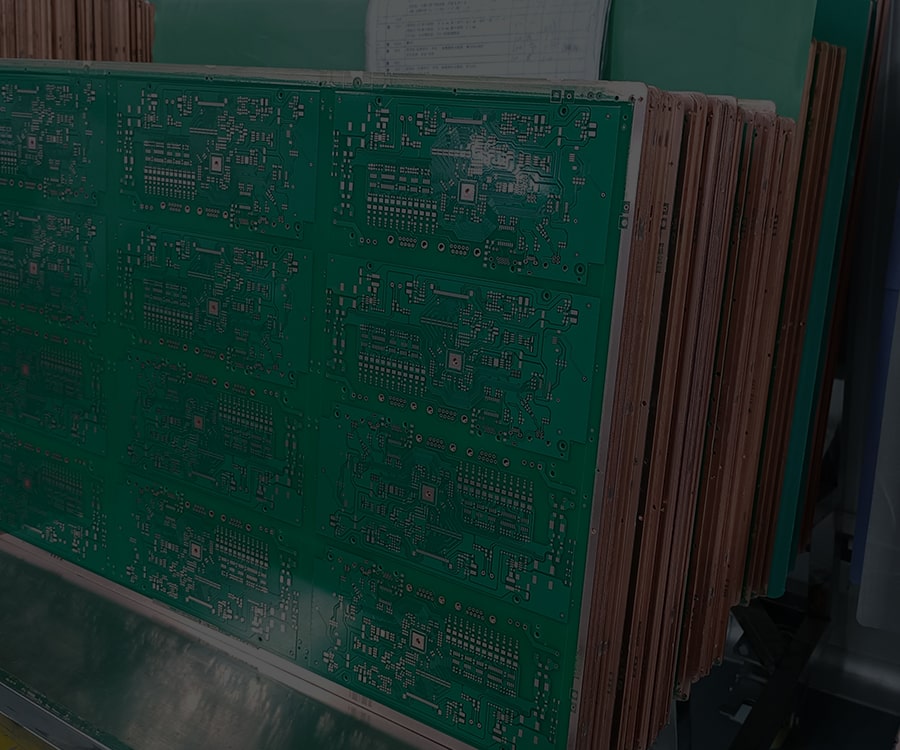

POE focuses on bare rigid PCB fabrication for prototypes and production runs since 2011. We build single- to multilayer FR-4 boards with tight impedance control, fine lines, and high reliability finishes such as ENIG, Immersion Tin, and HASL. Our UL- and ISO-certified facilities deliver fast, consistent quality for consumer, industrial, telecom, and medical applications.

From quick prototypes to volume orders, we provide engineering support, CAM optimization, and robust testing to ensure your bare boards are fabrication-ready and meet performance targets.

Send your Gerber and fabrication notes, and POE will manufacture bare rigid PCBs that meet your performance, reliability, and timeline targets. We support fine‑line routing, controlled impedance, HDI structures, and various surface finishes for consistent signal integrity and solderability across prototypes and mass production.

Still need help? Chat with us.

Are my design files safe when I submit them for bare rigid PCB fabrication?

Yes. We treat all Gerber/ODB++, drill, and fab notes as confidential and can sign an NDA upon request. Only authorized engineering and CAM staff access your data for manufacturing purposes.

What file formats do you accept for bare rigid PCBs?

We accept RS‑274X Gerber, ODB++, Excellon drill files, netlist, fabrication drawings, stackup, and impedance requirements. We also support exports from Altium, KiCad, Eagle, and more.

What is the typical lead time for bare rigid PCBs?

Prototypes ship in 3–5 days and standard production in 5–15 days depending on layer count, material, and finishes. Expedites are available—contact us for scheduling.

Do you provide impedance control and test coupons?

Yes. We manufacture impedance coupons per stackup and measure them to verify compliance. Controlled impedance tolerance is typically ±10% (tighter on review).

Which surface finishes are available for bare rigid PCBs?

ENIG, Immersion Tin, Immersion Silver, HASL/Lead‑free HASL, and OSP are available. We will recommend the best finish for assembly and storage needs.

Global logistics (expedited options available)

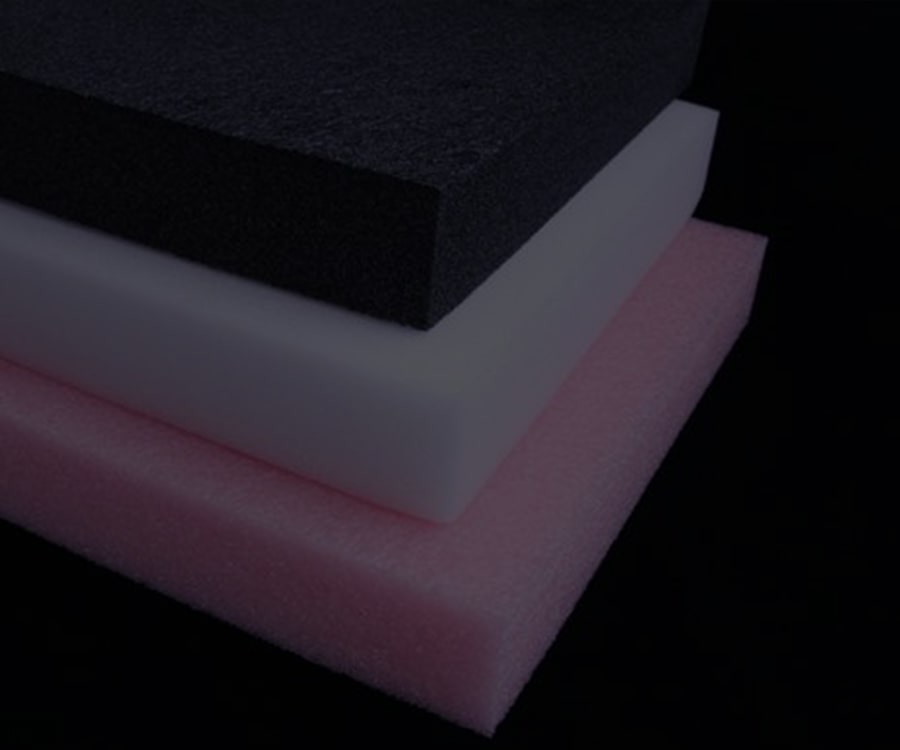

We package bare rigid PCBs with moisture barrier and ESD protection to ensure surface finish integrity and flatness in transit. Standard options include vacuum sealing, bubble wrap, and reinforced cartons. Worldwide door‑to‑door delivery is supported through trusted carriers.

Send Gerber/drill/fab notes to

all@poe-pcba.com

Receive a detailed quote

within 24 hours

Confirm PO and specifications

Engineering questions & CAM/DFM review

Start fabrication; typical 3–5 days

depending on layers

5–15 days based on quantity & complexity

Worldwide door‑to‑door shipping

Acceptance, feedback, and after‑sales service

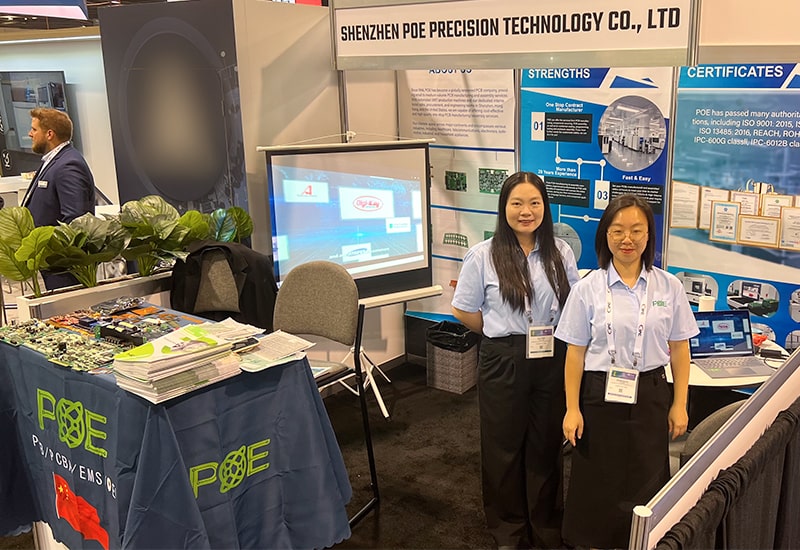

Meet the POE team at global electronics shows to discuss bare rigid PCB stackups, finishes, controlled impedance strategies, and quality standards. We share real build samples, coupons, and best practices to help you de‑risk fabrication and accelerate time‑to‑market.

Recent Bare PCB Orders

| User Name | Date | QTY | Price |

|---|

NEWS & EVENTS

Bare Rigid PCB Quality Week

POE showcased new process controls for impedance, solder mask alignment, and back‑drill verification—helping customers achieve predictable assembly results.

2025/01/12

Stackup & Material Seminar

Engineers discussed FR‑4 variants, high‑Tg options, and how copper distribution impacts impedance and warpage in bare rigid PCBs.

2024/12/25

DFM for Bare Boards Webinar

We shared CAM tips to reduce fab holds: annular ring rules, solder mask clearance, and controlled impedance routing guidelines.

2024/11/11

REQUEST A FREE CONSULTATION

Tell us your bare rigid PCB requirements, stackup, finish, and quantities. Upload Gerber and fab notes—our engineers will review and quote quickly.

All POE products are backed by:

24/7 After‑Sales Support

We can sign an NDA before file transfer so you can work with confidence.