Last week we hosted a visiting group from Italy at our facility.

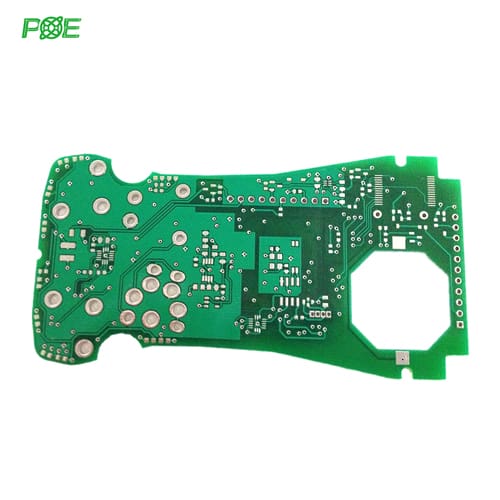

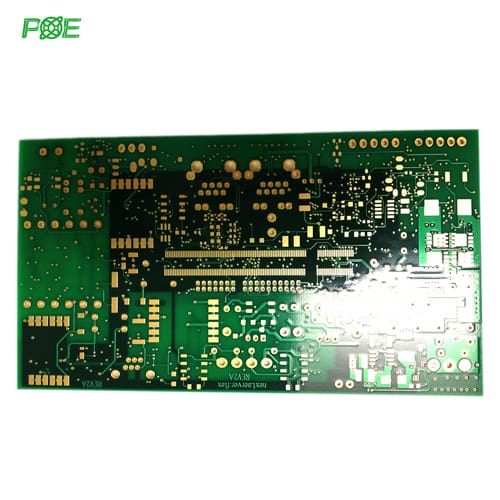

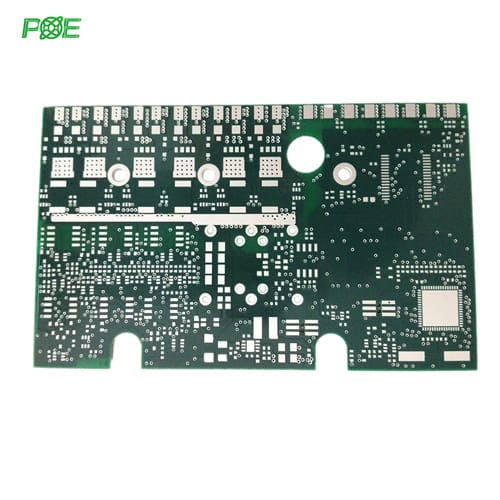

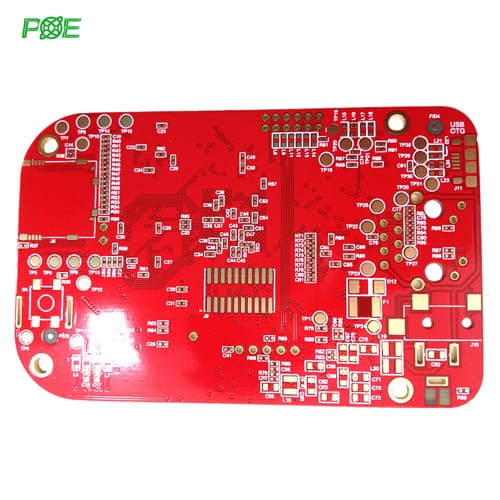

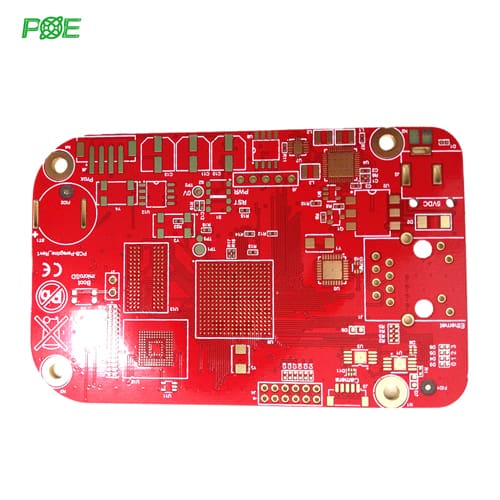

— POE PCB/PCBA Manufacturer (@poe_pcba) February 12, 2026

Always happy to open the line, share the process, and exchange ideas on quality + delivery control.

Want to visit POE for an on-site review? Send a message.#PCBA #PCB #FactoryVisit #Manufacturing #Quality pic.twitter.com/e5uisRH0IF

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China