Reflow defects rarely look dramatic — they look “almost fine.” ⚠

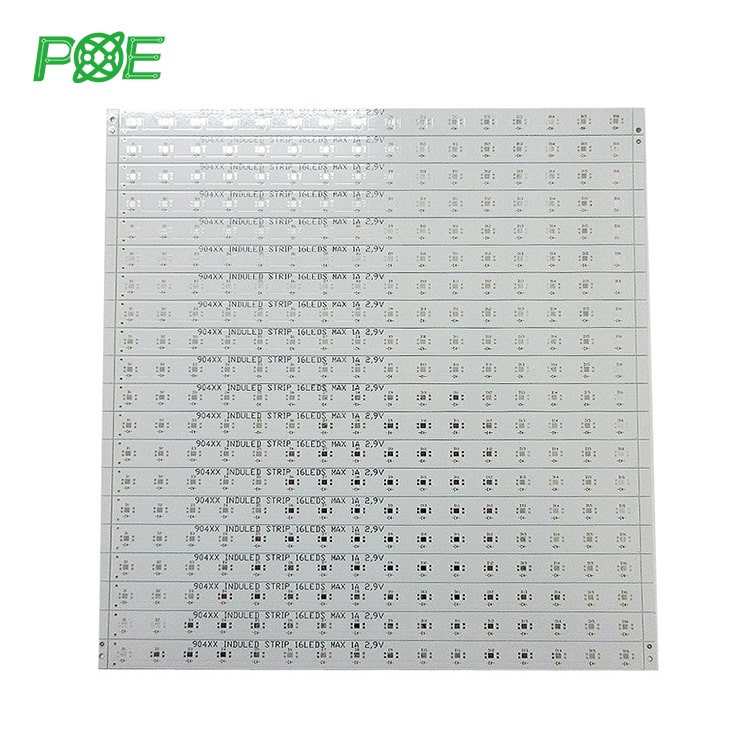

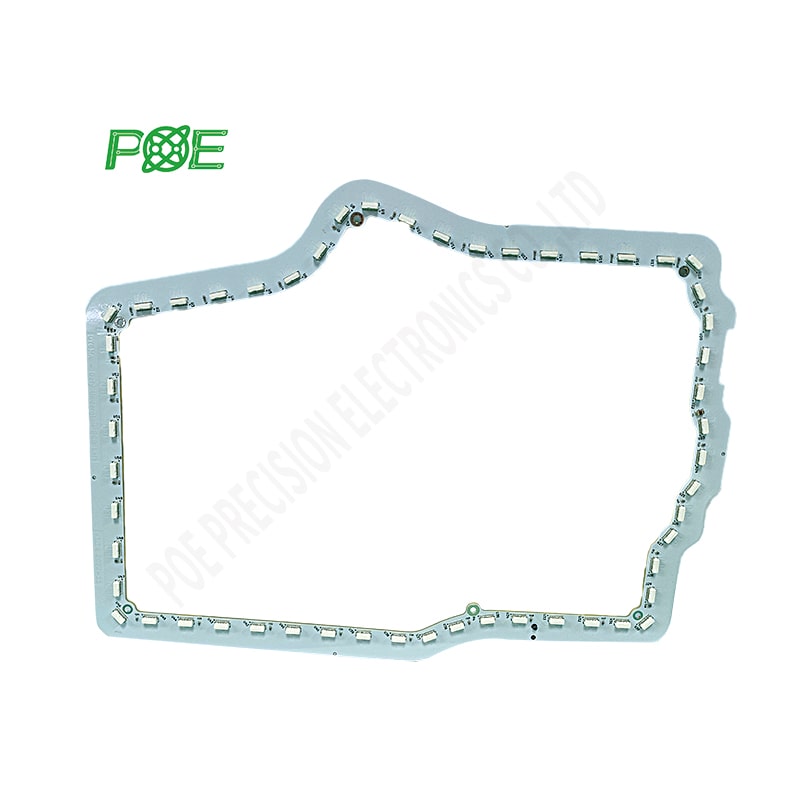

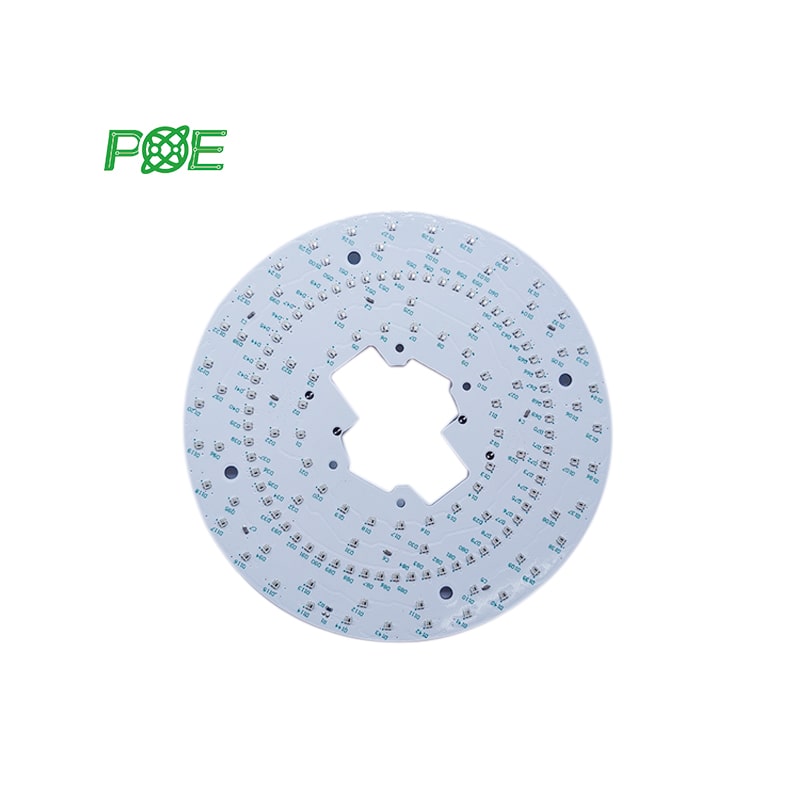

— POE PCB/PCBA Manufacturer (@poe_pcba) February 2, 2026

That’s why they’re expensive.

If your failures are intermittent and hard to reproduce, DM me your board size + copper distribution + key packages — I’ll send a quick screening checklist for reflow margin risk. pic.twitter.com/9YsQUj8uNq

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China