Our commitment to excellence is validated by internationally recognized certifications that ensure our products meet the highest quality standards.

Quality Management System

Environmental Management

Medical Device Quality

Soldering Requirements Standard

PCB Acceptability Standard

Assembly Acceptability

Hazardous Substances Restriction

Flammability Standard

Chemical Regulation Compliance

At POE, quality isn't just a promise—it's the foundation of everything we do. As a leading PCB manufacturer and assembly provider, we've implemented comprehensive quality management systems that exceed industry standards.

Our state-of-the-art facilities and rigorous testing procedures ensure that every product we deliver meets the highest specifications for performance, reliability, and durability.

We follow a comprehensive quality control process to ensure every PCB meets our rigorous standards.

All incoming materials undergo thorough inspection and testing to verify they meet our specifications before entering production.

Our advanced monitoring systems track every aspect of the manufacturing process in real-time to ensure consistency.

State-of-the-art equipment performs comprehensive electrical testing to verify functionality and identify potential defects.

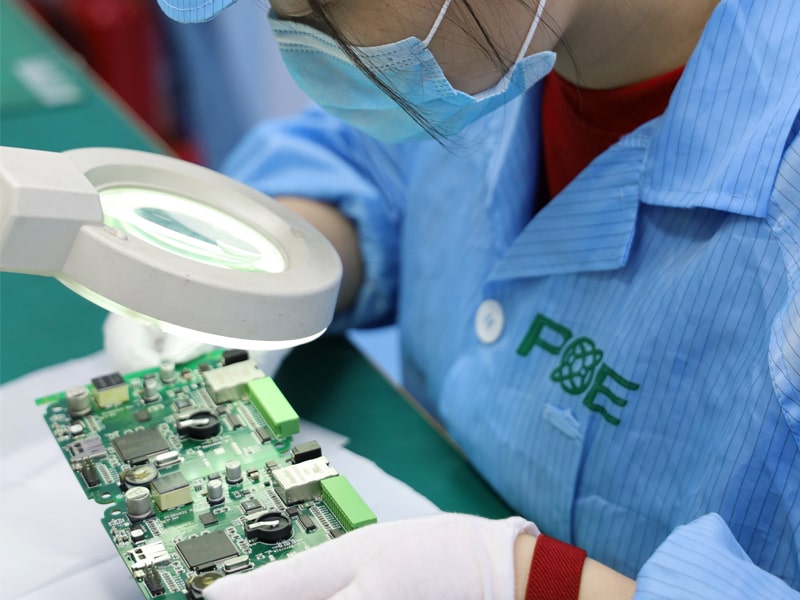

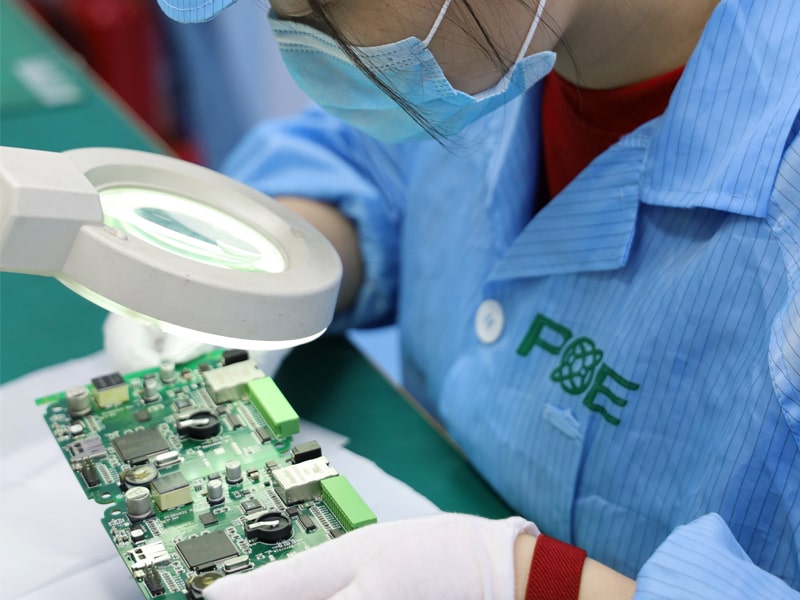

Trained quality control specialists perform detailed visual inspections to identify any cosmetic or structural issues.

Every product undergoes a final verification process to ensure it meets all quality standards before shipping to customers.

Complete transparency and professional documentation for every batch, ensuring full traceability and compliance with your quality requirements.

Every batch order comes with independent inspection records and traceability numbers, ensuring complete production process tracking, verification, and audit capabilities. Based on customer requirements, we provide the following professional-grade documents and reports:

Custom Quality Templates: If you need customized quality inspection templates that comply with your company's internal audit system, our engineering team will provide full cooperation and support throughout the process.

Our transparent processes, rigorous standards, and professional expertise ensure you receive not just quality products, but complete confidence in our manufacturing capabilities.

We invest in cutting-edge testing and inspection equipment to ensure the highest quality standards for our PCB products.

Our trained specialists perform detailed visual inspections using high-powered microscopes to identify cosmetic and structural defects that might affect performance or reliability.

Before full production begins, we perform a comprehensive inspection of the first production piece to verify all design specifications are met and manufacturing processes are properly calibrated.

Our advanced AOI systems use high-resolution cameras and sophisticated algorithms to detect microscopic defects invisible to the human eye, ensuring consistent quality across all production runs.

Our X-ray inspection systems allow us to see through multiple PCB layers to inspect hidden solder joints, BGA components, and internal structures that cannot be visually inspected by other means.

Our ICT systems verify electrical connections, component values, and circuit functionality by making direct electrical contact with the PCB through custom-designed test fixtures.

We develop custom functional test fixtures that simulate real-world operating conditions to verify that assembled PCBs perform according to specifications under actual use scenarios.

Our commitment to quality has earned the trust of industry leaders worldwide.

Partner with us for PCB solutions that meet the highest quality standards in the industry.