Ensuring signal integrity for high-speed design and RF applications. We provide precise impedance control solutions to meet your most demanding design requirements.

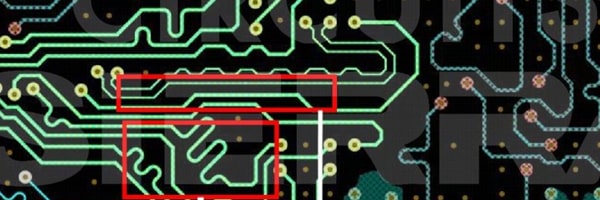

In high-speed PCBs, impedance is the resistance that signals encounter when propagating through transmission lines. When impedance is discontinuous, it causes signal reflections, distortion, and timing issues.

Think of transmission lines on a PCB as water pipes, and signals as water flow. Impedance is like the diameter and smoothness of the pipe. If the pipe has uneven thickness (impedance variations), the water flow will create turbulence and reflections (signal distortion).

Ideal square wave signal on well-matched transmission lines

Signal reflections and distortion caused by impedance mismatch

Maintain waveform quality of high-speed digital signals during transmission, avoiding signal reflections and crosstalk

Good impedance control reduces unnecessary electromagnetic radiation and improves system EMC performance

Stable impedance control ensures consistency and reliability in mass production

In high-frequency applications, precise impedance control is the foundation for stable system operation