POE specializes in precision SMT stencils and custom tooling solutions, bringing over a decade of expertise in laser cutting technology and advanced manufacturing processes. We make PCB assembly simple and reliable:

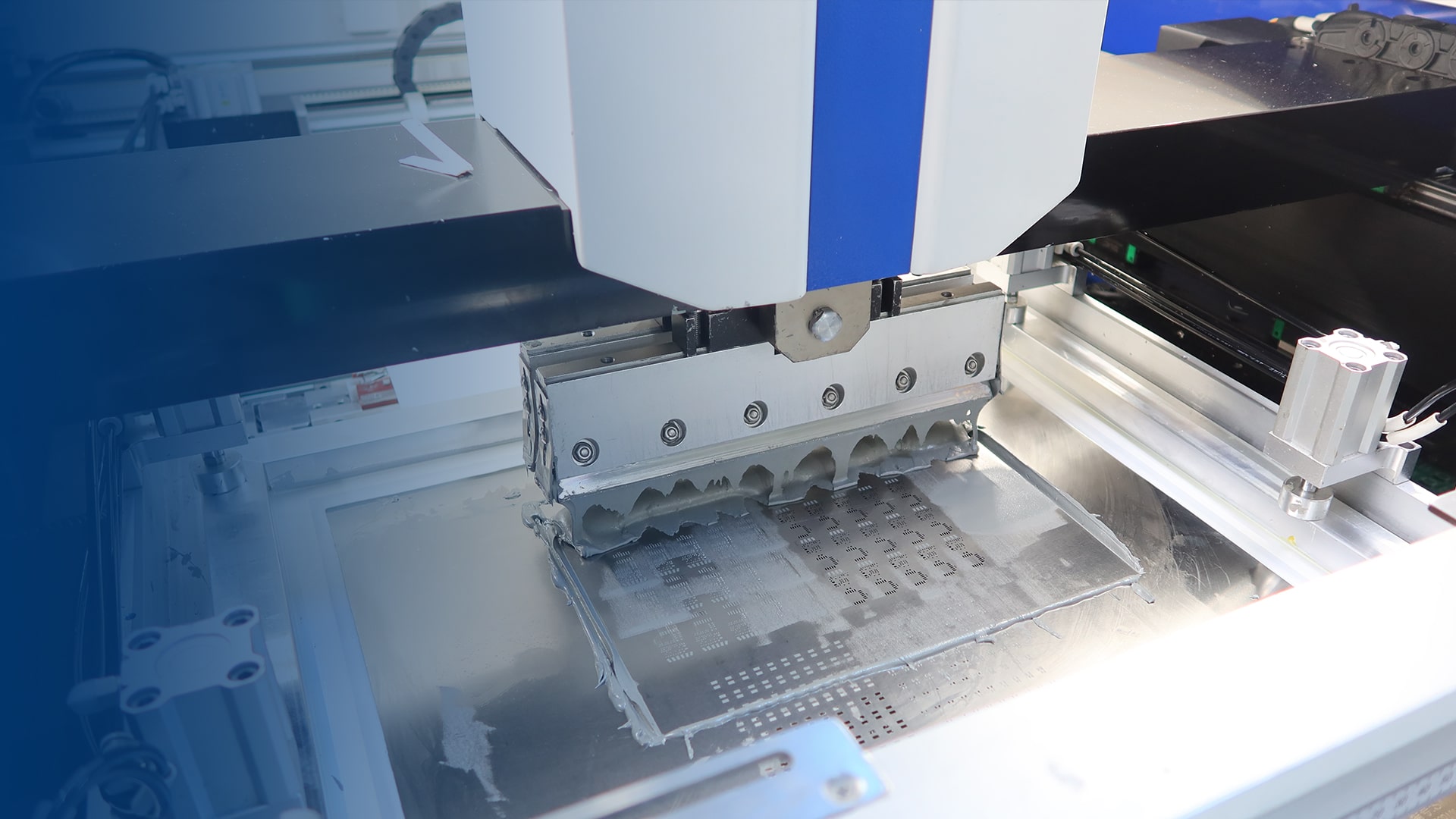

POE delivers high-precision laser-cut SMT stencils and custom tooling solutions designed to optimize your PCB assembly process. Our advanced laser cutting technology ensures accurate aperture dimensions and smooth sidewalls for consistent solder paste deposition.

With over a decade of experience in PCB manufacturing, we understand the critical role that quality stencils play in achieving reliable solder joints. Our stencils are manufactured using premium stainless steel materials and undergo rigorous quality control to meet the demanding requirements of modern electronics assembly.

POE specializes in manufacturing precision SMT stencils and custom tooling solutions that enhance your PCB assembly efficiency. From prototype to high-volume production, we deliver laser-cut stencils with exceptional accuracy and consistency to meet your exact specifications.

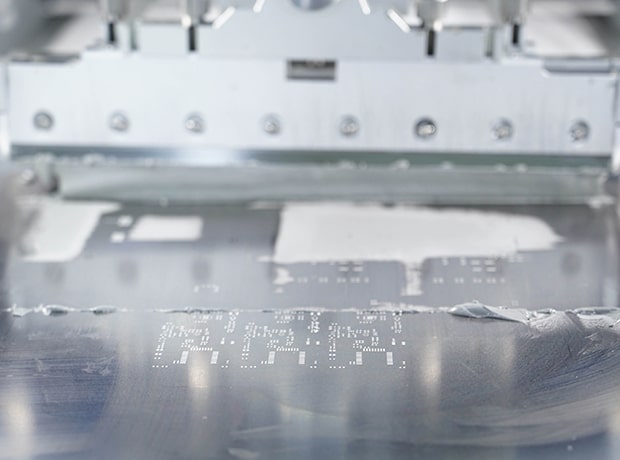

High-precision stencils with smooth aperture walls for optimal paste release

Specialized fixtures and jigs for your assembly requirements

Fast turnaround for development and testing phases

Multi-thickness designs for complex component layouts

Ultra-fine pitch capabilities for advanced packaging

Comprehensive testing and validation of all stencils

POE provides precision SMT stencils and tooling solutions that ensure consistent, high-quality assembly results for your PCB projects.

POE is committed to delivering precision SMT stencils and tooling solutions that meet the highest industry standards. Our advanced laser cutting technology, combined with rigorous quality control processes, ensures consistent performance and reliability for your PCB assembly operations.

Advanced laser cutting technology for superior stencil quality.

Our state-of-the-art laser cutting systems deliver precise aperture dimensions with smooth sidewalls, ensuring optimal solder paste release and consistent print quality. Every stencil undergoes rigorous dimensional inspection to meet your exact specifications.

Fast turnaround times from prototype to production.

POE understands the importance of speed in product development. Our streamlined manufacturing process enables rapid delivery of prototype stencils within 24-48 hours, while maintaining the same quality standards for production volumes.

Comprehensive quality assurance and international certifications.

According to ISO 9001:2015, 13485:2016, and IPC standards certification, we guarantee superior stencil quality. Our quality control process includes dimensional verification, surface finish inspection, and aperture wall smoothness testing.

REQUEST A FREE CONSULTATION

Fill in the form with vour requirements and ouantity unloan the relevant documents and we will provide you with a free quote right away!

For All Products Purchased From Us, If You Encounter Any Quality:

Offer "24/7 After-sales Support".

Before sending us the files, you can sign a NDA with us to ensure you can choose us with complete confidence.

⚠ POE: Visual inspection (VI) fails when “OK” isn’t defined.

— POE PCB/PCBA Manufacturer (@poe_pcba) January 23, 2026

No spec → shift-to-shift opinions: rework good boards / ship marginal ones.

We standardize defect limits + lighting/mag + reference photos — so decisions repeat.#PCBA pic.twitter.com/pNk81F0f9f

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China