Your trusted global electronics manufacturing partner

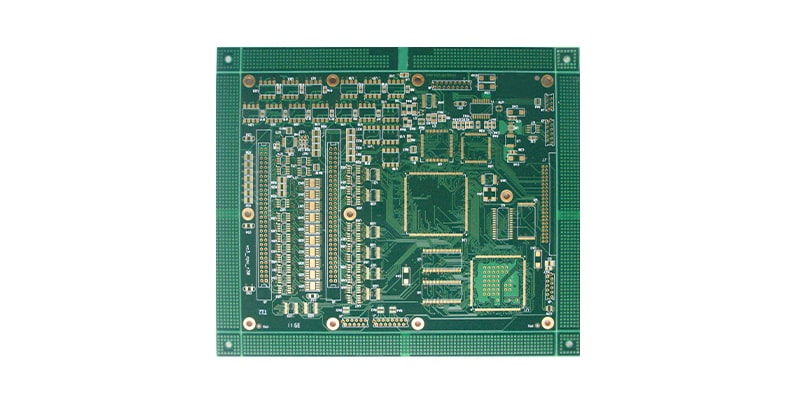

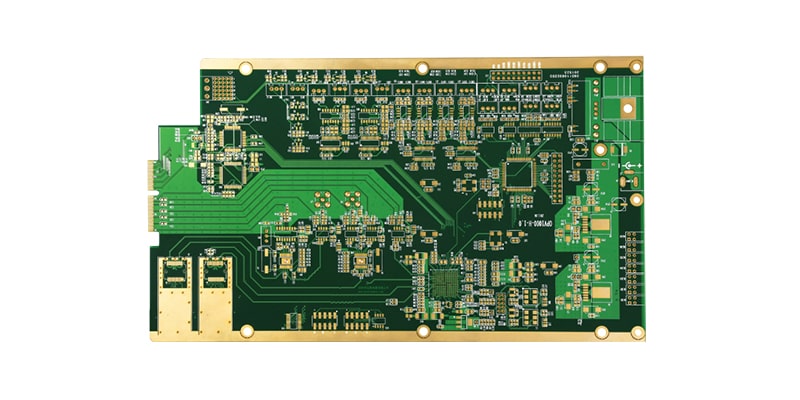

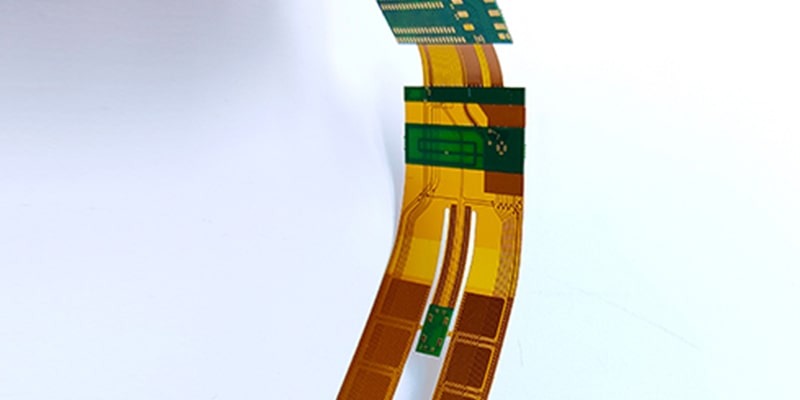

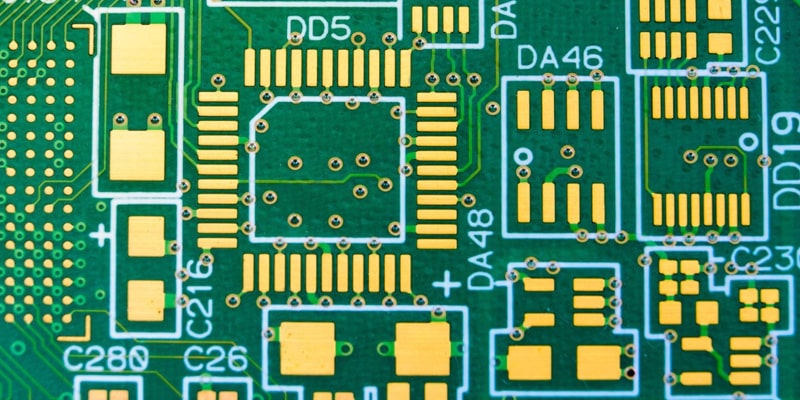

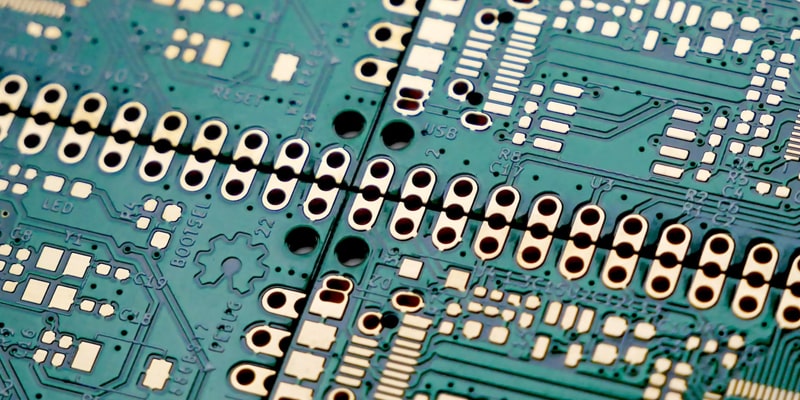

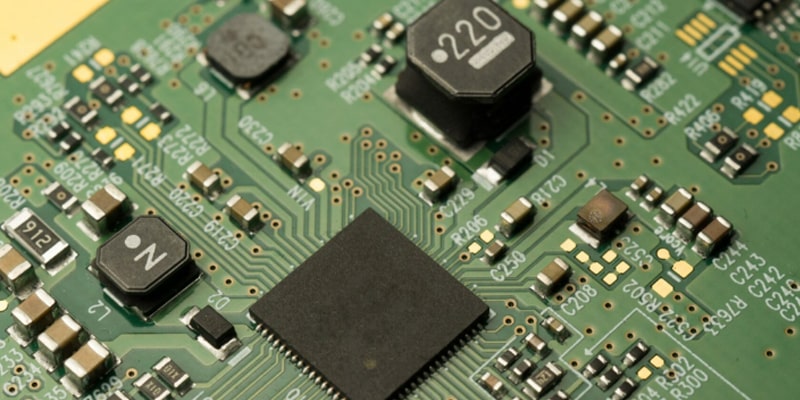

Since 1996, POE has established itself as a leading PCB manufacturer specializing in high-precision printed circuit board fabrication. Our state-of-the-art facility features advanced PCB production lines including multilayer lamination, HDI technology, and rigid-flex capabilities. With dedicated engineering teams across Shenzhen, Hong Kong, and the United States, we deliver superior quality PCB solutions from prototype to mass production. Our PCB manufacturing serves diverse industries including medical devices, 5G telecommunications, automotive electronics, industrial controls, and consumer electronics worldwide.

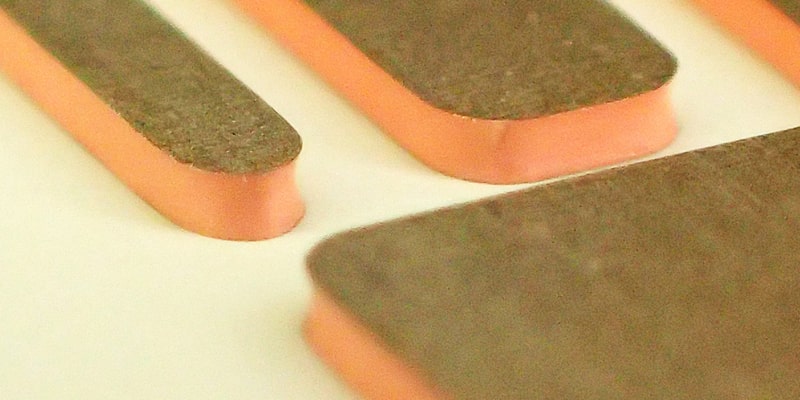

Premium FR4 substrate preparation and cutting

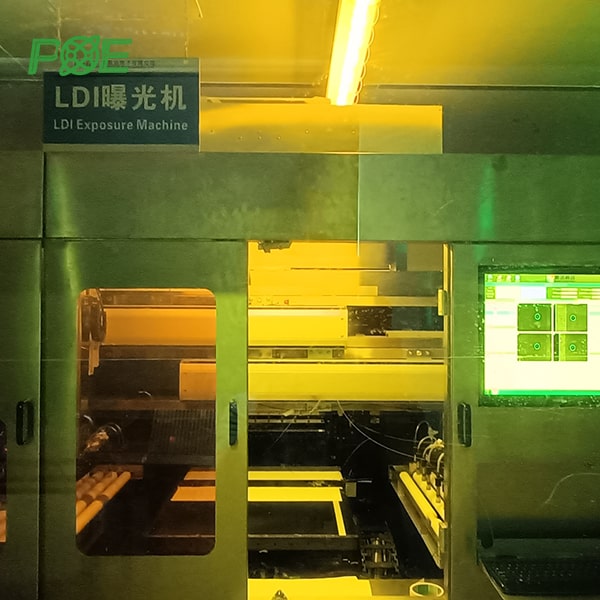

UV lithography for inner layer patterning

Photoresist application and exposure process

Chemical removal of unwanted copper traces

Automated optical verification of inner circuits

Oxide treatment for layer adhesion

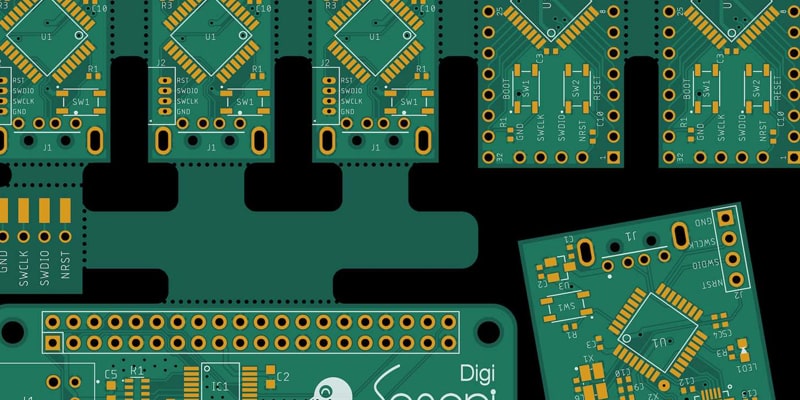

Multi-layer PCB pressing and bonding

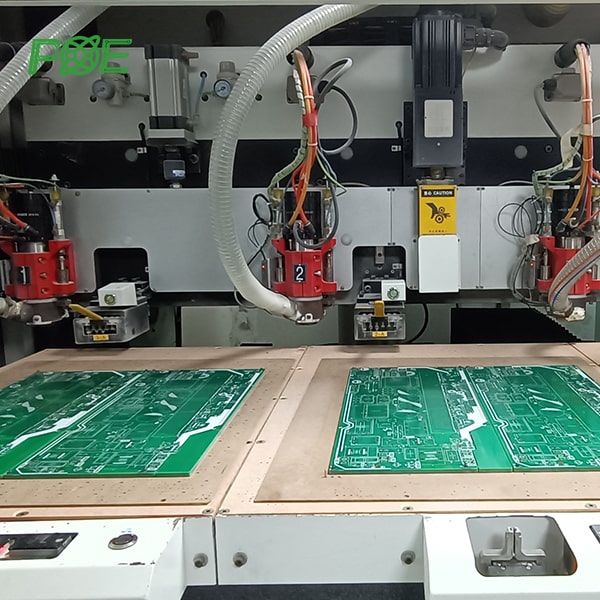

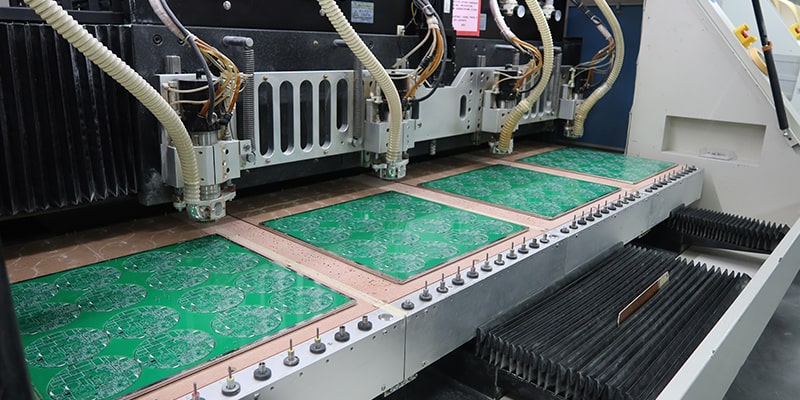

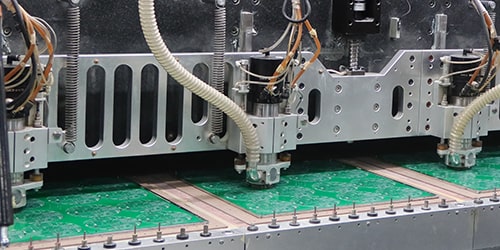

High-precision via and mounting hole drilling

Photoresist removal after processing

Plated through-hole copper deposition

External layer photoresist patterning

Electroplating copper in drilled holes

Final copper trace definition and cleaning

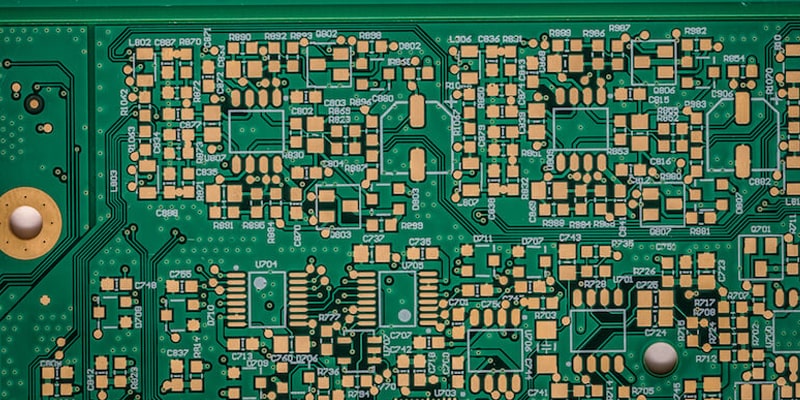

Final circuit pattern verification

X-ray inspection of internal connections

Protective coating application and curing

Component legends and marking printing

Precision board profiling and routing

Electrical continuity and isolation testing

Final quality control and inspection

Automated electrical testing system

Comprehensive electrical verification

Moisture-free protective packaging

HASL, ENIG, OSP, and immersion silver finishes

DFM analysis and PCB layout optimization

Advanced via-in-pad and via filling technology

Complex via structures

Heavy copper PCB

cost-effective production

Complete OEM facility with comprehensive contract manufacturing solutions

35 BOM sourcing engineers offering 1-day quote service

ISO9001:2015 and ISO13485:2016 certified manufacturing

Medical, 5G, Robot, IOT, and Power Supply PCBA solutions

Excellent quality and fast delivery. Their team understood our medical device requirements perfectly.

Outstanding PCBA manufacturing partner. Professional service and competitive pricing for our IoT products.

Reliable partner for our 5G equipment. Their technical expertise and quality control are impressive.

Factory Address:

Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

SMT line ready—then a $0.08 part stops it.

— POE PCB/PCBA Manufacturer (@poe_pcba) March 4, 2026

Wrong revs + "equivalents" + weak traceability = last-minute swaps, unstable lots, lost days.

POE locks AVL early + verifies incoming vs BOM/traceability.

DM “BOM” for a fast risk check. #PCBA #SupplyChain pic.twitter.com/CaNeV2FkTf

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China