Comprehensive and reliable testing services to ensure your PCBA products meet the highest quality standards

We utilize state-of-the-art testing equipment to ensure the highest quality standards for your PCBA products.

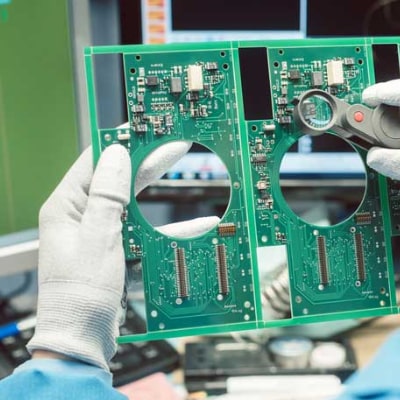

- Manually inspect PCBs;

- Low cost;

- Detect PCB soldering issues;

- Suitable for small batch production of simple PCBA designs.

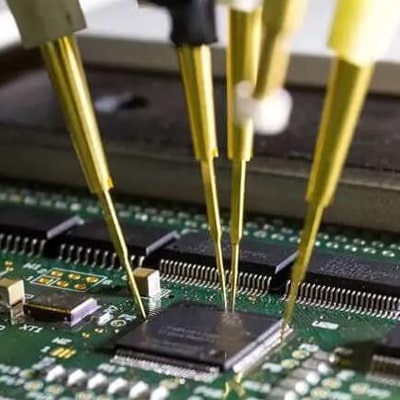

- Software operated machine testing;

- Can detect any faults;

- Can test resistance and capacitance;

- Expensive.

- Detection of solder paste less tin, more tin, tip, tin type, etc., can measure solder paste height, volume, area, data visible, suitable for SMT production lines of electronic manufacturing enterprises.

- It is used for the first part inspection in the SMT production process, which can detect the welding quality and electrical performance of SMT chip components.

- Testing before and after the PCBA enters the wave soldering or reflow process;

- Scanning PCB surface defects with high-resolution cameras.

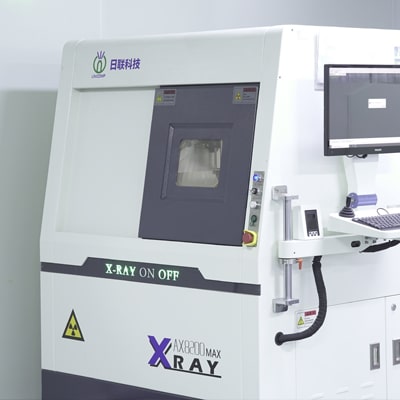

- Use X-ray imaging to find hidden defects in PCBs;

- For ball grid array and chip level package testing;

- Has the highest detection rate of all inspection methods.

- Open temperature and climate testing for PCBs and electronic components;

- Stress testing of PCBs under extreme conditions;

- Potentially shortens the life of the PCB;

- Ensures product reliability.

- Test the operation of the board by simulating the operating environment;

- Perform this test at the end of the production cycle;

- Does not require any specialized equipment, which is less expensive.

We analyze your PCBA requirements and design a customized testing plan

Our experts perform detailed visual inspections to identify obvious defects

We utilize advanced equipment for thorough automated testing

We verify that your PCBAs function correctly in simulated environments

Final quality assurance and certification of your PCBA products

Contact our team today to discuss your PCBA testing requirements

Last week we hosted a visiting group from Italy at our facility.

— POE PCB/PCBA Manufacturer (@poe_pcba) February 12, 2026

Always happy to open the line, share the process, and exchange ideas on quality + delivery control.

Want to visit POE for an on-site review? Send a message.#PCBA #PCB #FactoryVisit #Manufacturing #Quality pic.twitter.com/e5uisRH0IF

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China