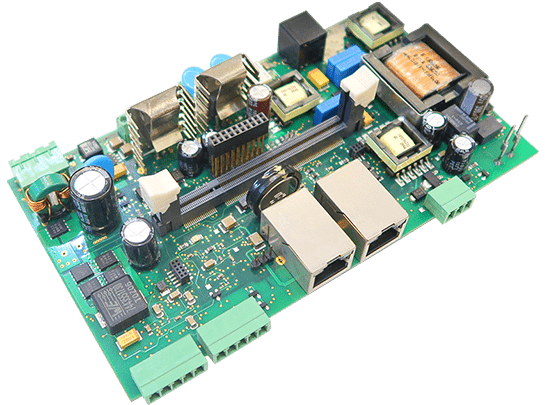

POE focuses on the fabrication of bare flexible printed circuit boards (FPCs) for rapid prototyping and volume production. We process PI and PET-based flex cores with RA or ED copper, delivering stable roll-to-roll consistency and tight dimensional control for dynamic bend applications.

Our dedicated flex lines support precision etching, micro drilling/laser vias, coverlay application, and surface finish for bare FPCs ready for downstream assembly. From thin single-layer jumpers to multilayer flex with impedance control, we build to your design intent and reliability targets.

Bare flexible PCBs enable ultra-thin, lightweight, and highly bendable interconnects for compact devices. Provide your Gerber and stack-up intent, and POE fabricates stable bare flex circuits with consistent copper uniformity and excellent bend fatigue performance. Ideal for dynamic flexing, tight enclosures, and weight-sensitive designs.

POE’s bare flex manufacturing complies with ISO9001, ISO14001, ISO13485 and RoHS/REACH requirements. UL and IPC standards are followed to ensure traceability, safety, and consistent quality across prototypes and mass runs.

ISO9001

ISO14001

ISO13485

REACH

IPC

SGS

RoHS

Global logistics (expedited options available)

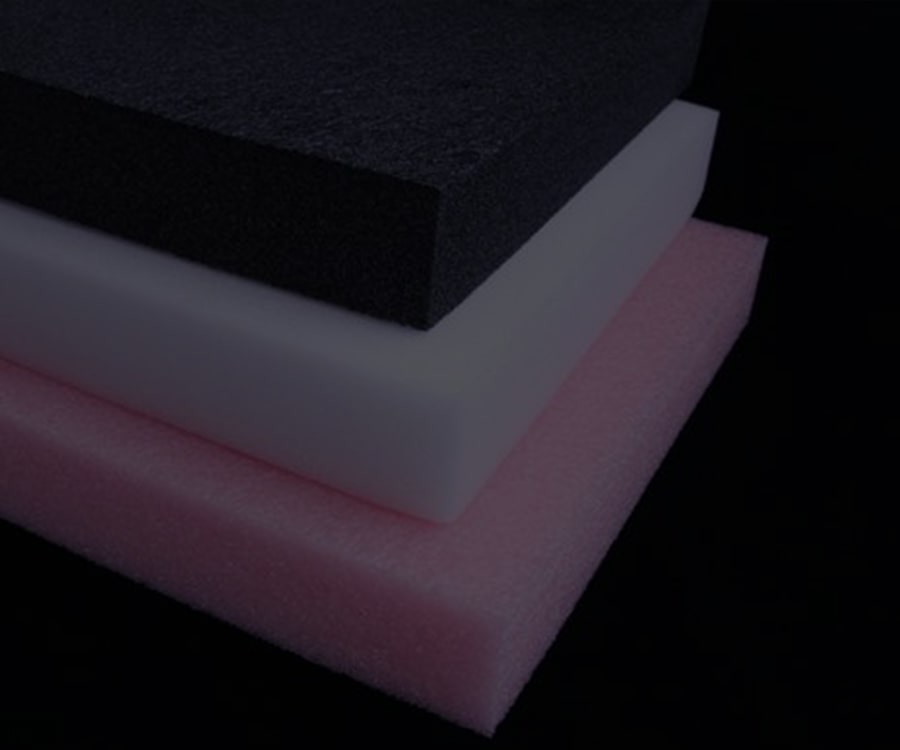

Bare FPCs are moisture-controlled and protected with ESD packaging, cushioned with bubble wrap, and boxed for international transit. We support vacuum sealing and reel/roll packing as requested to fit your assembly workflow and storage conditions.

Send Gerber and stack-up to

all@poe-pcba.com

Receive a tailored quote

within 24 hours

PO confirmed and

schedule locked

DFM and EQ for bare flex;

final CAM approval

Start fabrication;

typ. 2–4 days

Scale to volume

1–15 days by qty

Door-to-door

worldwide shipping

Feedback welcomed;

after-sales available

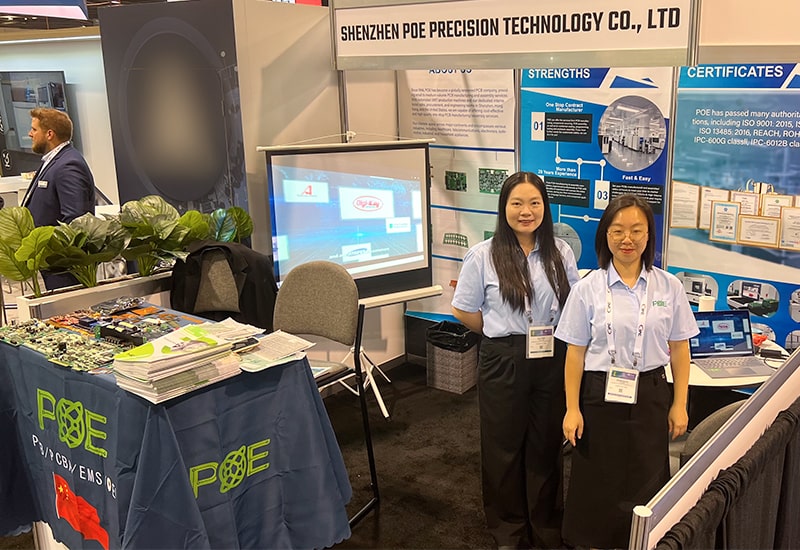

Meet POE at global electronics exhibitions to learn how bare flexible circuits can reduce weight, improve reliability in dynamic movements, and simplify assembly in space-constrained products. Ask our team for live samples and capability charts.

Recent Bare Flex Orders

| User Name | Date | QTY | Price |

|---|

NEWS & INSIGHTS

Design Tips for Bare Flex: Bend Radius & Trace Routing

Learn how to select proper bend radii, staggered traces, and copper balancing techniques to maximize flex life and avoid cracking in dynamic applications.

2025/1/12

PI vs. PET: Choosing the Right Flex Base

Compare mechanical endurance, temperature limits, and cost to pick the optimal material system for your bare FPC design.

2024/12/25

Surface Finishes for Bare Flex

When to use ENIG, OSP, or hard gold pads on bare flexible circuits to balance solderability and cost.

2024/11/11

REQUEST A FREE CONSULATION

Tell us your bare flex requirements (layers, material, thickness, finish, impedance). Upload Gerber/stack-up and we’ll quote immediately.

For any quality concerns on delivered bare flex:

We offer 24/7 after-sales support.

NDA available on request before file transfer for full confidentiality.