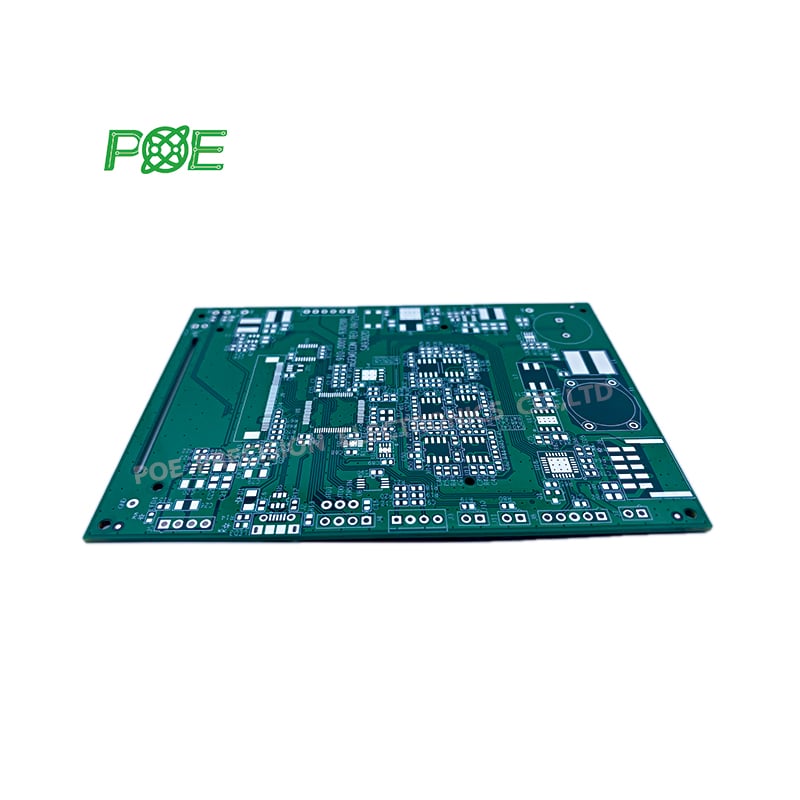

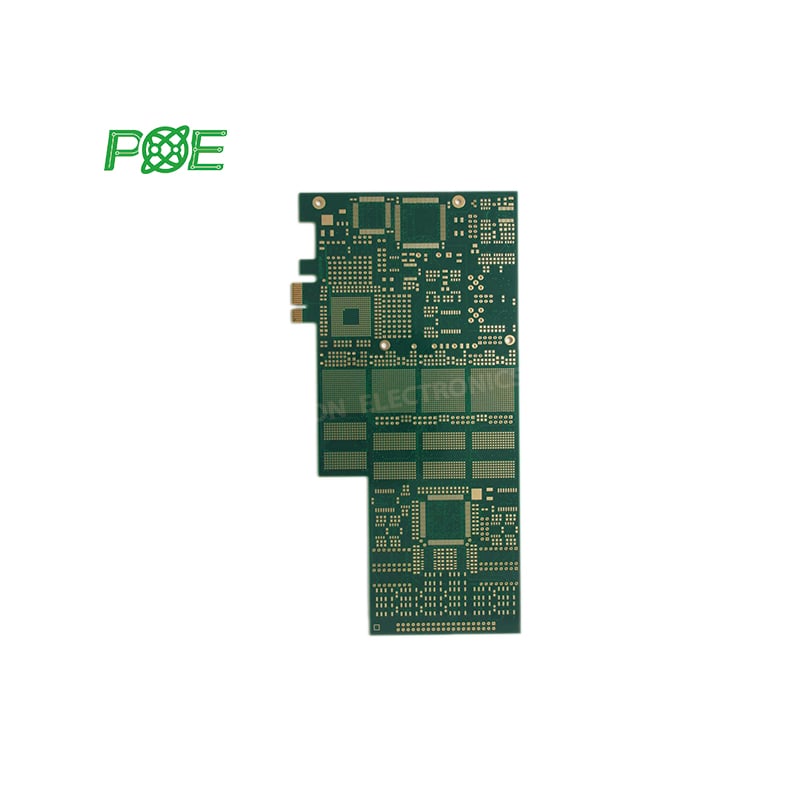

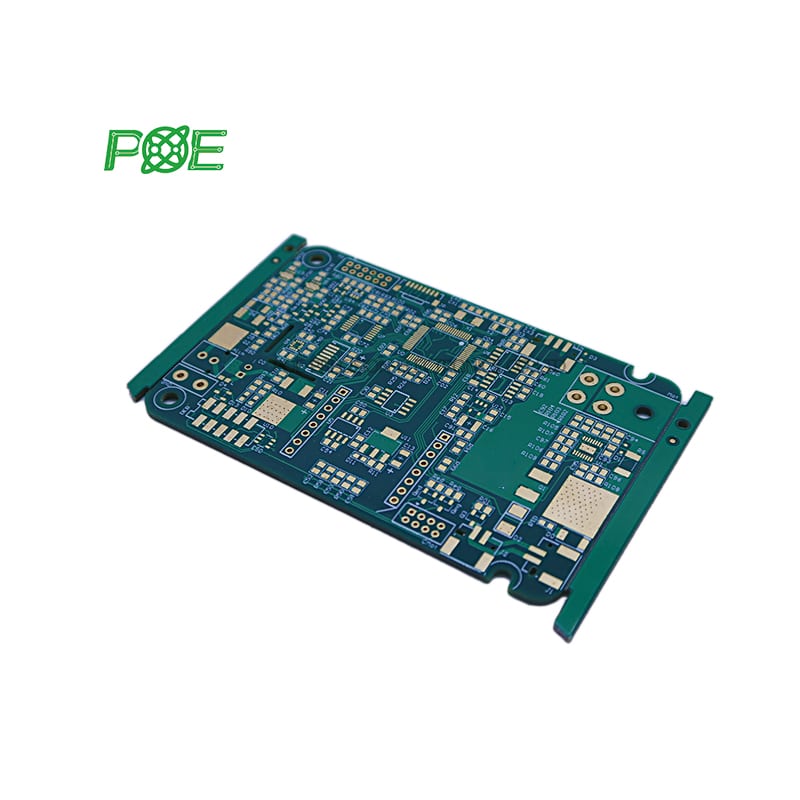

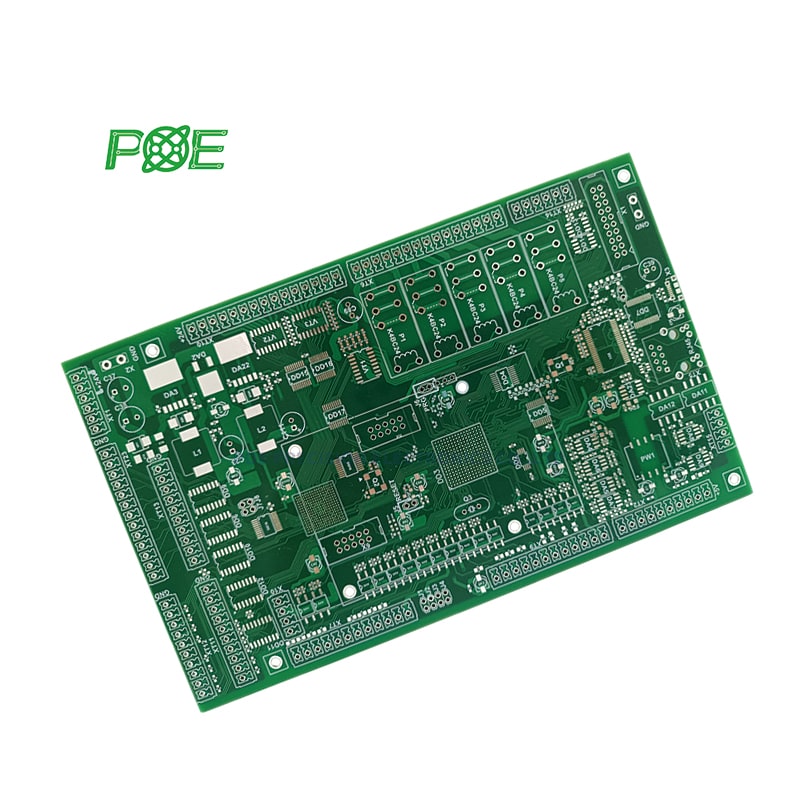

Layers

4 - 40+ layers, with various HDI structures including 1+N+1, 2+N+2, 3+N+3, and ELIC (Every Layer Interconnect) technology

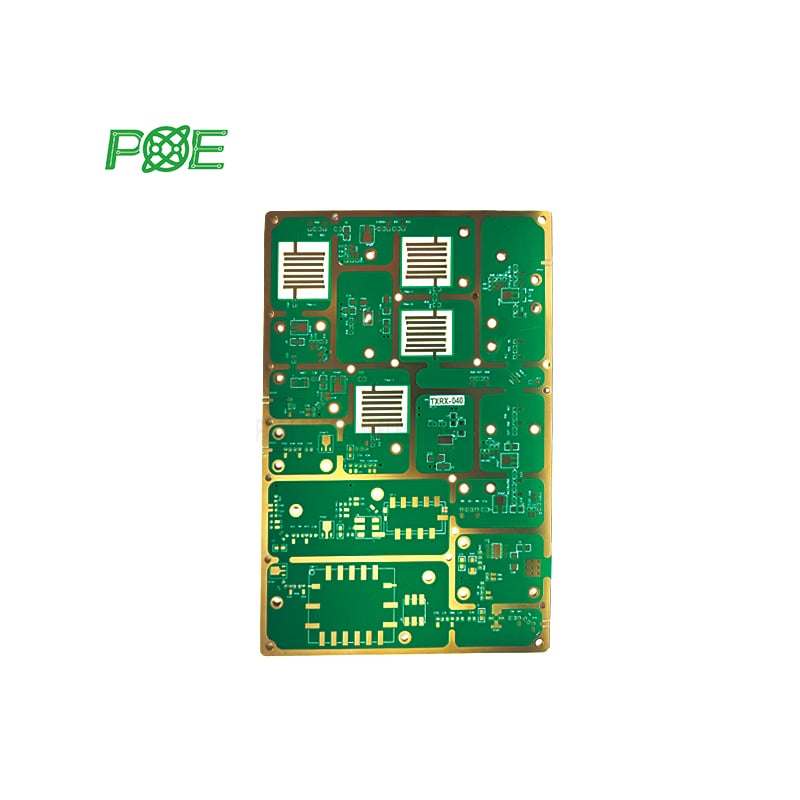

Material

FR-4, High Tg FR-4, Halogen-free, Rogers (RO4350B, RO3003), Isola

Board Thickness

0.2mm - 6.0mm with precise thickness control

Copper Thickness

0.5 oz - 6 oz (17.5μm - 210μm) with multi-level copper capability

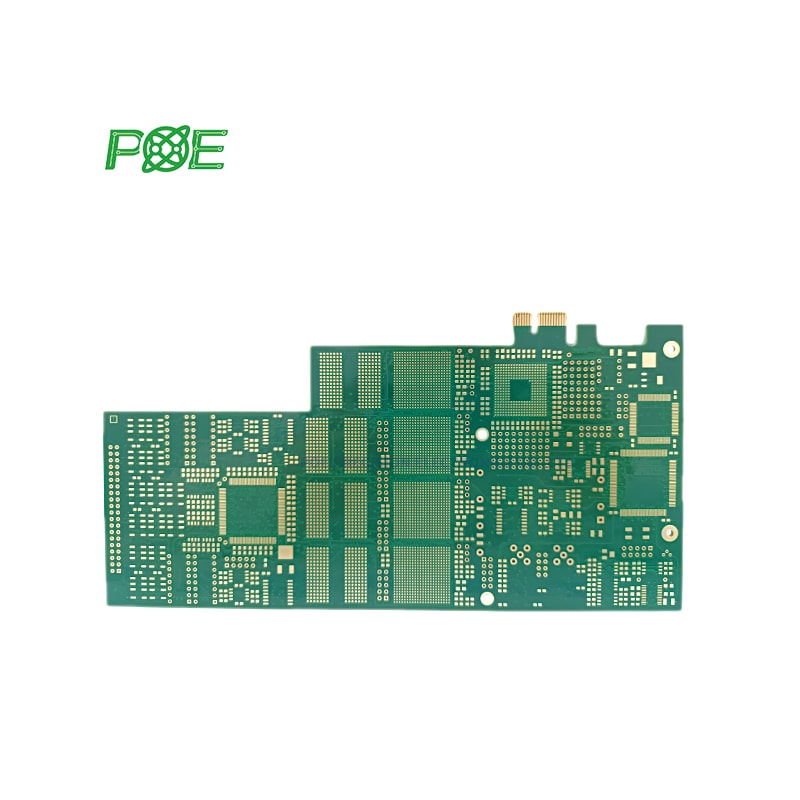

Minimum Hole Size

0.1mm for mechanically drilled vias, 0.075mm for laser-drilled microvias with aspect ratio control

Minimum Trace/Space Width

Industry-leading capability of 2 mils (50μm) standard, with advanced capability down to 1 mil (25μm) for high-density designs

Via Technology

Blind/Buried vias, Stacked vias, Via-in-Pad (filled and plated), and Skip vias for optimal routing solutions

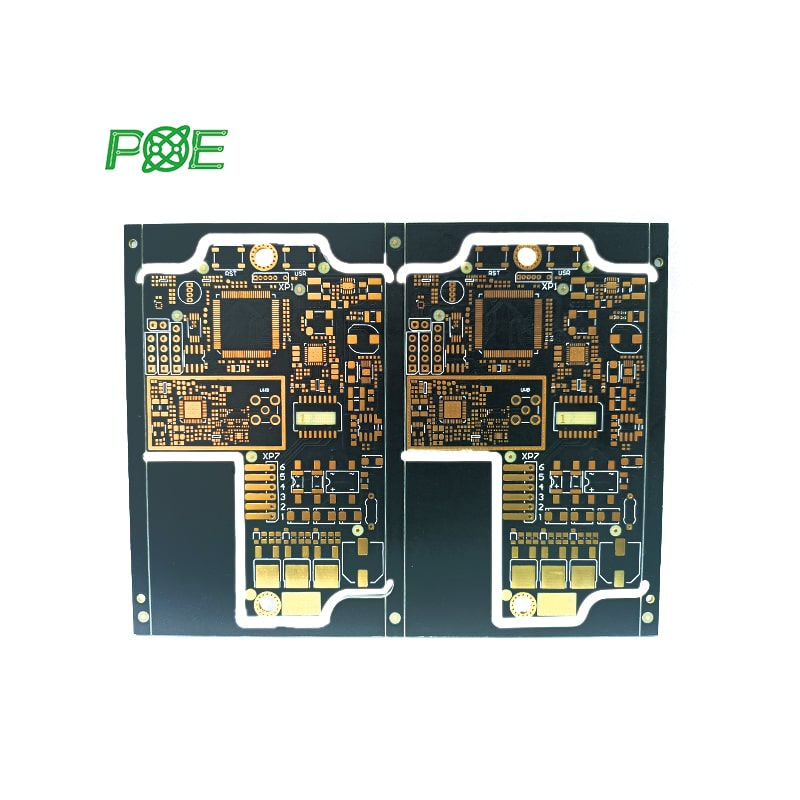

Solder Mask

LPI (Liquid Photo-Imageable) in Green, Yellow, White, Black, Blue, Red, and custom colors with ±1.0mil registration accuracy

Silkscreen

White, Black, Yellow, and custom colors with high-resolution printing capability

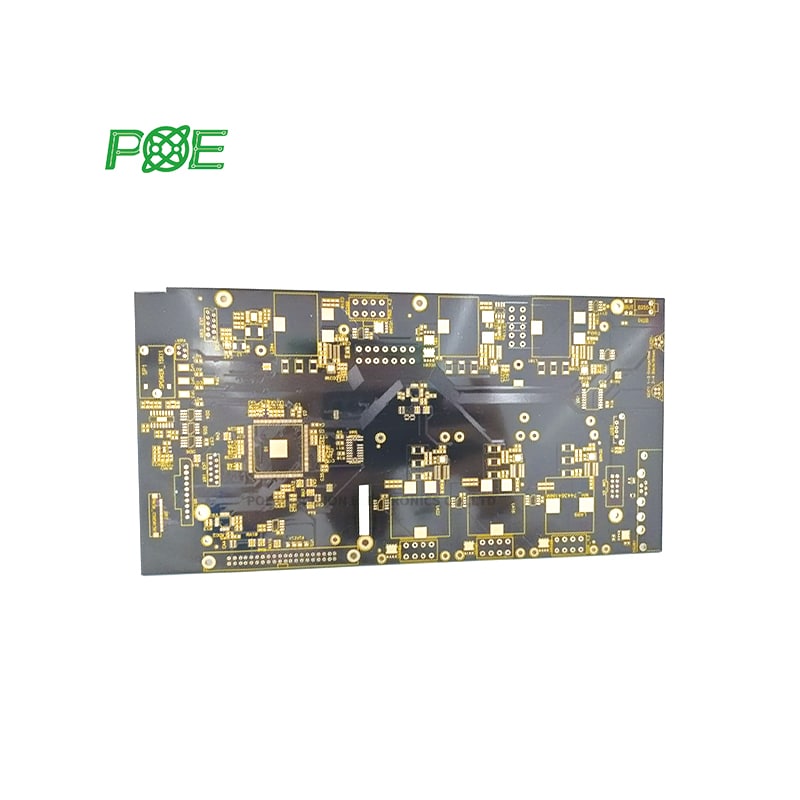

Surface Finishes

ENIG (3-5μin gold), OSP, Immersion Silver, Immersion Tin, HASL, and Hard Gold (30μin+) for specific applications

Minimum Annular Ring

2 mils (50μm) for outer layers, 1 mil (25μm) for inner layers, supporting high-reliability designs

Controlled Impedance

Tolerance of ±8% standard, with ±5% available for critical applications, verified by TDR testing

Special Features

Embedded passive components (resistors, capacitors), rigid-flex designs, back drilling, sequential lamination, and high-frequency material processing

Quality Assurance

100% electrical testing, impedance testing, cross-section analysis, and thermal stress testing

Certifications

ISO 9001, ISO 14001, UL, IPC-A-600 Class 2/3, RoHS and REACH compliant

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China