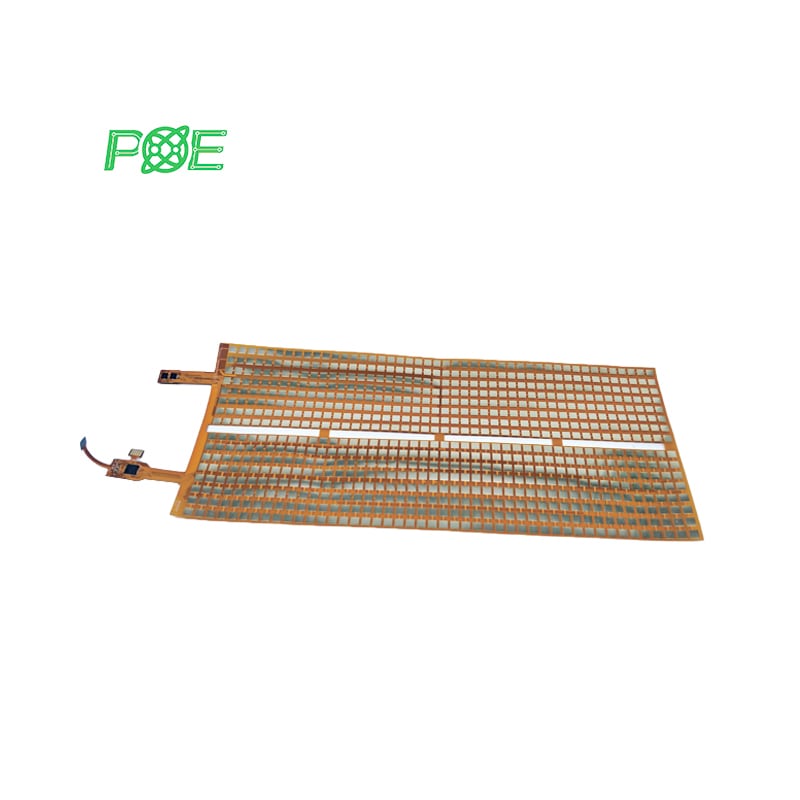

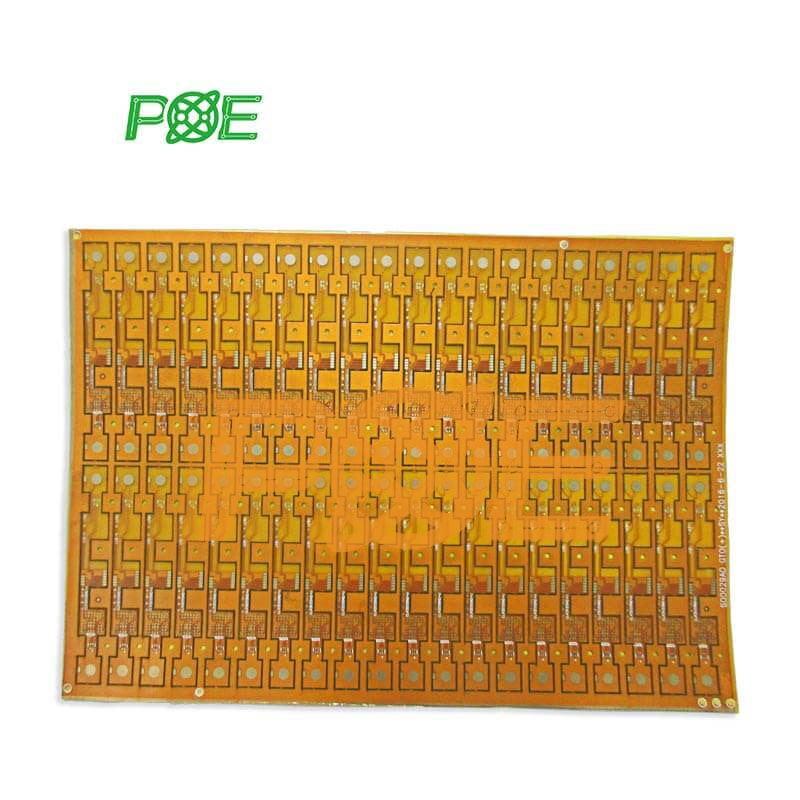

⚠ POE: Visual inspection (VI) fails when “OK” isn’t defined.

— POE PCB/PCBA Manufacturer (@poe_pcba) January 23, 2026

No spec → shift-to-shift opinions: rework good boards / ship marginal ones.

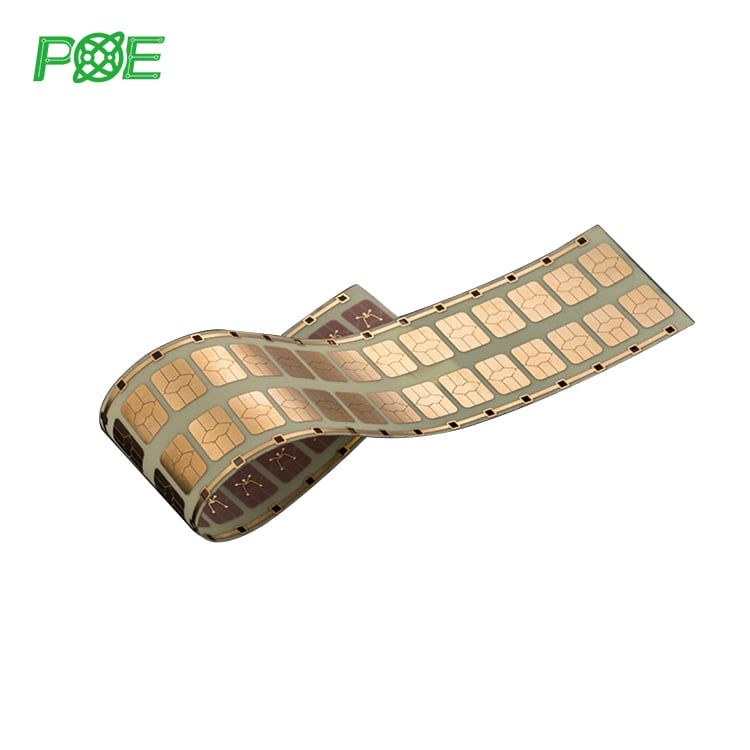

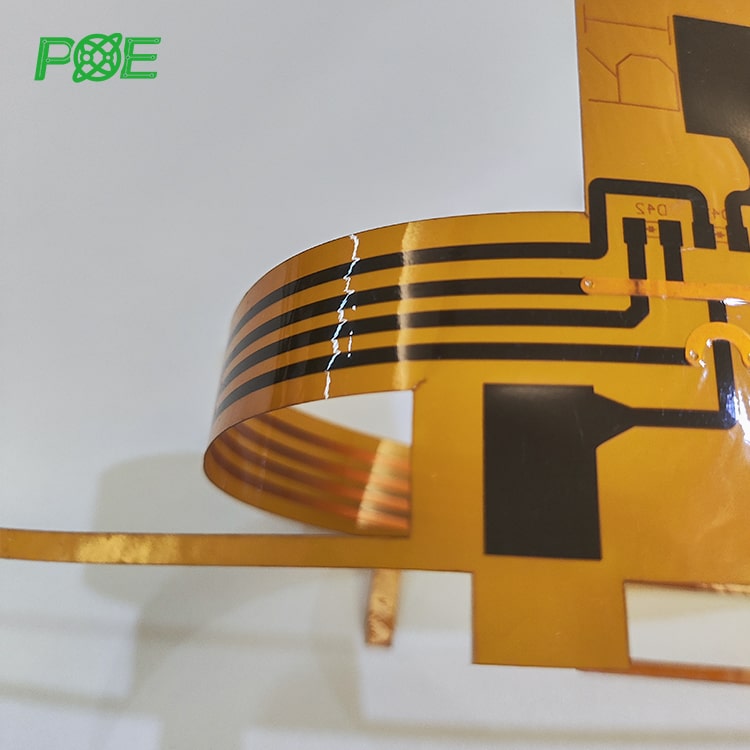

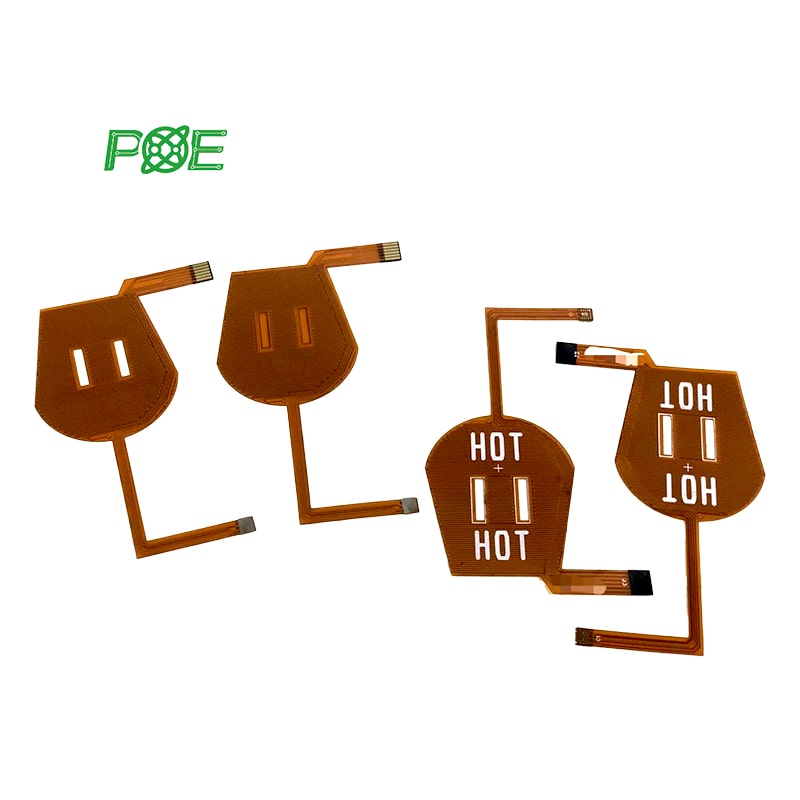

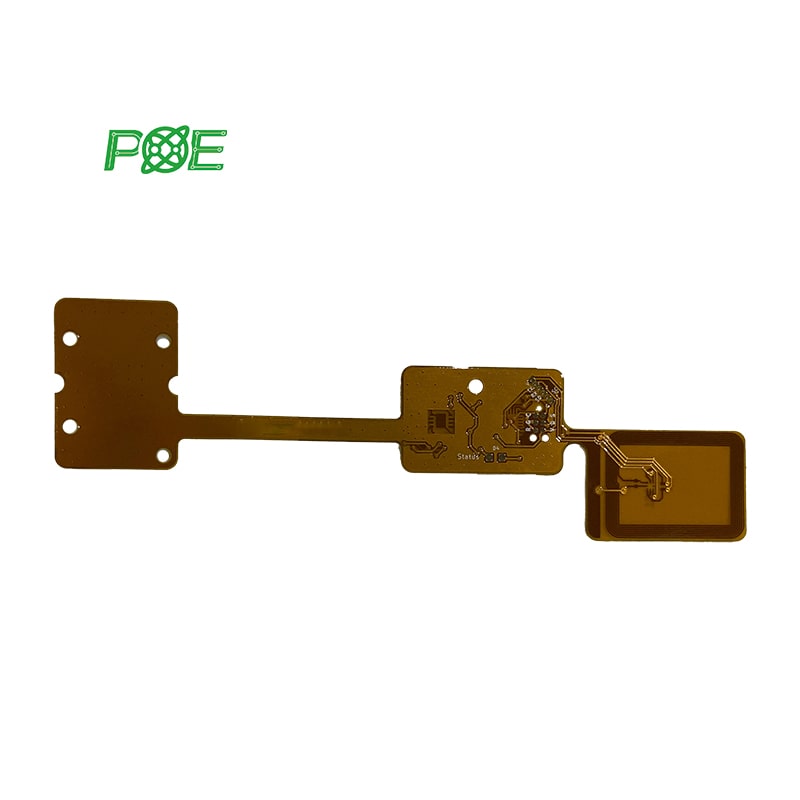

We standardize defect limits + lighting/mag + reference photos — so decisions repeat.#PCBA pic.twitter.com/pNk81F0f9f

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China