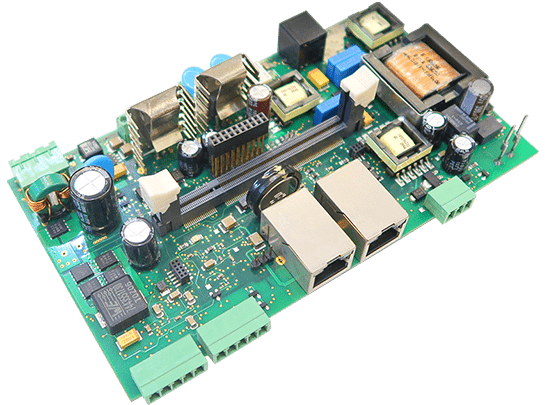

POE specializes in advanced HDI (High Density Interconnect) PCB fabrication with microvias, sequential lamination, and ultra-fine pitch capabilities since 2011. We manufacture 1+N+1 to 3+N+3 HDI structures with laser-drilled microvias down to 50μm, supporting complex multilayer designs for smartphones, tablets, wearables, and high-performance computing applications.

Our state-of-the-art facilities feature advanced laser drilling systems, precise sequential build-up processes, and comprehensive electrical testing to deliver HDI boards that meet the most demanding miniaturization and performance requirements.

Submit your HDI design files and stackup requirements, and POE will manufacture advanced HDI PCBs with precise microvia formation, sequential build-up layers, and ultra-fine pitch capabilities. We specialize in complex HDI structures including stacked microvias, skip vias, and any-layer HDI configurations for next-generation electronic devices requiring maximum miniaturization and performance.

Still need help? Chat with us.

What HDI structures can POE manufacture?

We manufacture 1+N+1 to 3+N+3 HDI structures with laser-drilled microvias, stacked and staggered configurations, skip vias, and any-layer HDI designs. Our advanced sequential build-up process supports complex multilayer HDI requirements.

What is the minimum microvia size you can achieve?

Our laser drilling systems can produce microvias as small as 50μm diameter with precise aspect ratios. We support copper-filled microvias, via-in-pad designs, and maintain tight tolerances for high-density interconnect applications.

What is the typical lead time for HDI PCBs?

HDI prototypes require 5–7 days due to sequential lamination processes, while production runs take 7–18 days depending on HDI complexity and layer count. Complex 3+N+3 structures may require additional time.

How do you ensure HDI quality and reliability?

We perform comprehensive testing including cross-section analysis, microvia inspection, impedance verification, and 100% electrical testing. Our sequential build-up process includes quality checkpoints at each lamination cycle.

What materials are suitable for HDI applications?

We use low-loss dielectrics, modified epoxy resins, and specialized prepregs optimized for HDI processing. Materials include low-Dk/Df options for high-frequency applications and thermally stable substrates for reliability.

Global logistics (expedited options available)

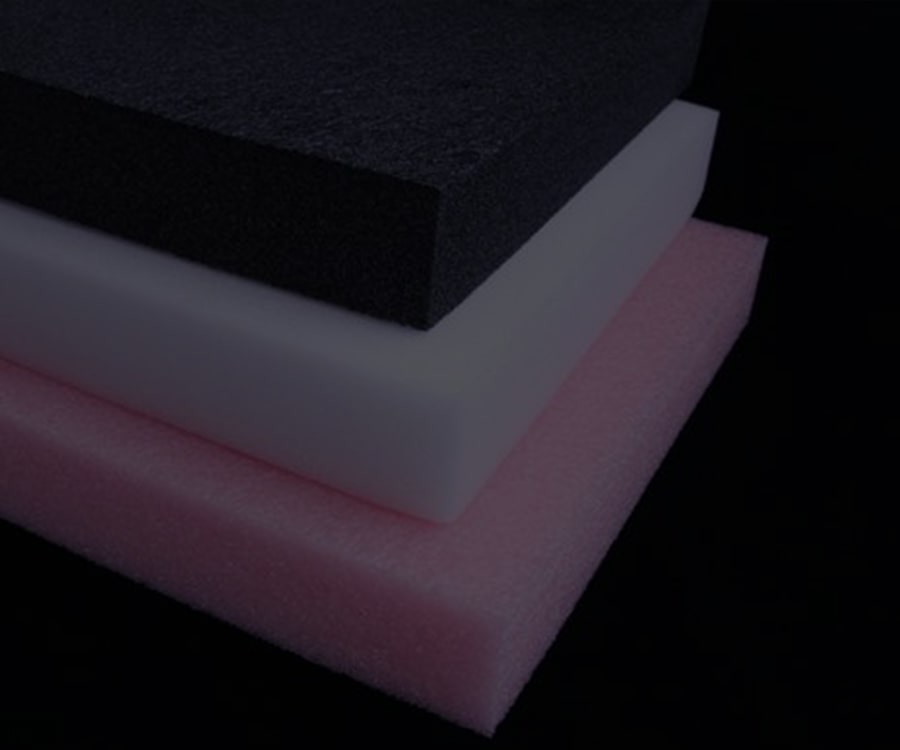

We package bare PCBs with moisture barrier and ESD protection to ensure surface finish integrity and flatness in transit. Standard options include vacuum sealing, bubble wrap, and reinforced cartons. Worldwide door‑to‑door delivery is supported through trusted carriers.

Send Gerber/drill/fab notes to

all@poe-pcba.com

Receive a detailed quote

within 24 hours

Confirm PO and specifications

Engineering questions & CAM/DFM review

Start fabrication; typical 3–5 days

depending on layers

5–15 days based on quantity & complexity

Worldwide door‑to‑door shipping

Acceptance, feedback, and after‑sales service

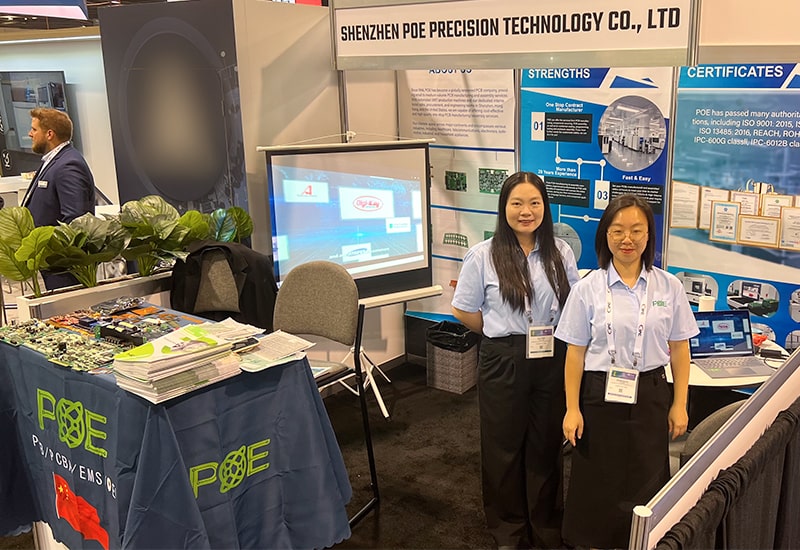

Meet the POE team at global electronics shows to discuss bare PCB stackups, finishes, controlled impedance strategies, and quality standards. We share real build samples, coupons, and best practices to help you de‑risk fabrication and accelerate time‑to‑market.

Recent Bare PCB Orders

| User Name | Date | QTY | Price |

|---|

REQUEST A FREE CONSULTATION

Tell us your bare rigid PCB requirements, stackup, finish, and quantities. Upload Gerber and fab notes—our engineers will review and quote quickly.

All POE products are backed by:

24/7 After‑Sales Support

We can sign an NDA before file transfer so you can work with confidence.