Our streamlined process eliminates supply chain complexities, ensuring quality and efficiency at every stage

Thorough inspection of PCBs and components to ensure quality from the start

High-performance SPI ensures precise solder paste application

High-speed SMT equipment with ±0.025mm placement accuracy

Precise temperature profile control for perfect soldering results

Automated and manual insertion with wave soldering capabilities

Comprehensive testing including ICT, FCT, AOI, and burn-in testing

Protective coatings and final product assembly services

Custom packaging solutions to meet your specific requirements

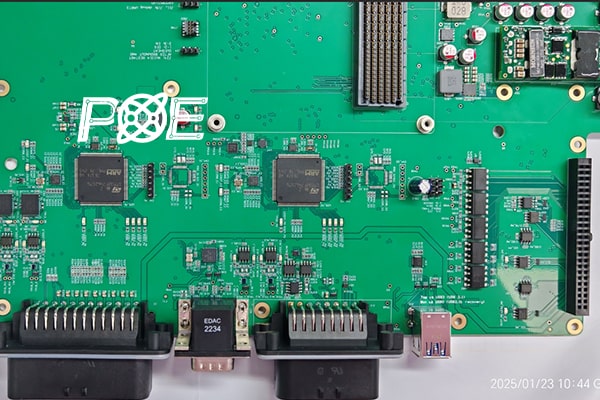

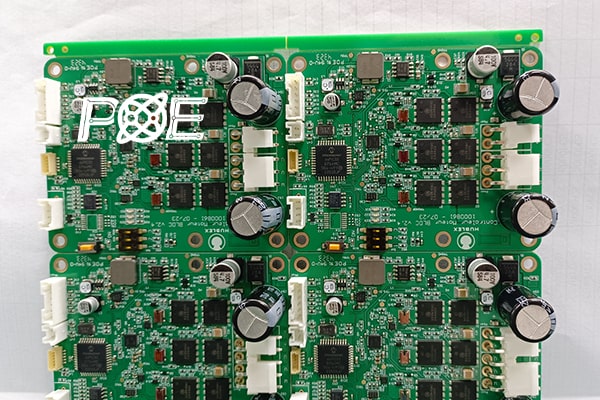

Our advanced SMT equipment and processes ensure high-precision assembly for your most demanding projects

| Parameter | Specification |

|---|---|

| SMT Production Lines | 10 High-speed Automated SMT Lines |

| Daily Capacity | 300K CPH (Components Per Hour) |

| Minimum Component Size | 01005 (0402 Metric) |

| BGA Min. Pitch | 0.35mm |

| Placement Accuracy | ±0.025mm |

| Production Volume | Prototype, Small to Mass Production |

| DIP Capability | Automated/Semi-automated Through-hole Lines |

| Soldering Process | Lead-free Reflow, Wave Soldering, Hand Soldering |

| Item | Description |

|---|---|

| Inspection Equipment | AOI, X-RAY, ICT, FCT |

| Quality Certifications | ISO9001, ISO14001, ISO13485 |

| Process Standards | IPC-A-610 Class 2&3 |

| Traceability | Full Material Tracking System |

| Warranty Period | 12 Months |

| Service | Details |

|---|---|

| BOM Sourcing | One-stop Component Procurement Service |

| DFM Analysis | Free DFM Review and Suggestions |

| Technical Support | 24/7 Professional Technical Assistance |

| Quick Prototyping | 48-hour Express Service Available |

| Packaging Solutions | Customized Packaging Options |

We eliminate your supply chain headaches with our global procurement network and expertise

Partnerships with authorized distributors worldwide ensuring genuine components and stable supply

Expert component substitution to reduce costs and mitigate supply chain risks

Procure and manage" services to reduce your capital investment and storage needs

Early warnings for component shortages and end-of-life parts to prevent production delays

Rigorous testing protocols ensure your PCBA meets the highest quality standards

High-resolution cameras detect soldering defects and component placement issues

Critical for BGA inspection, verifying solder joints and internal connections

Verifies component presence, orientation, and values for manufacturing defects

Simulates real-world operating conditions to ensure proper functionality

Extended operation under elevated temperatures to identify early failures

Adherence to IPC-A-610 Class 2/3 standards with comprehensive documentation

Discover how we've helped clients across industries with complex PCBA challenges

Advanced PCBA solutions for generalist superhumanoid robots capable of performing all core warehouse tasks.

High-reliability PCBA for aerospace data recording systems operating in harsh environments.

From bare PCB prototyping to PCBA sample production and planned bulk manufacturing transfer from Europe to China.

Our commitment to excellence sets us apart in the PCBA manufacturing industry

From component sourcing to final assembly, we handle everything for a seamless experience

Stable procurement channels and cost control through our global network

Advanced equipment combined with strict quality standards and processes

Serving diverse industries with proven expertise in complex PCBA projects

Upload your BOM and Gerber files for a complete quote or contact our engineering team for technical consultation