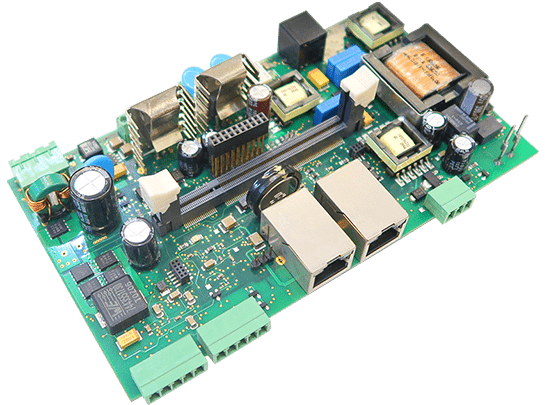

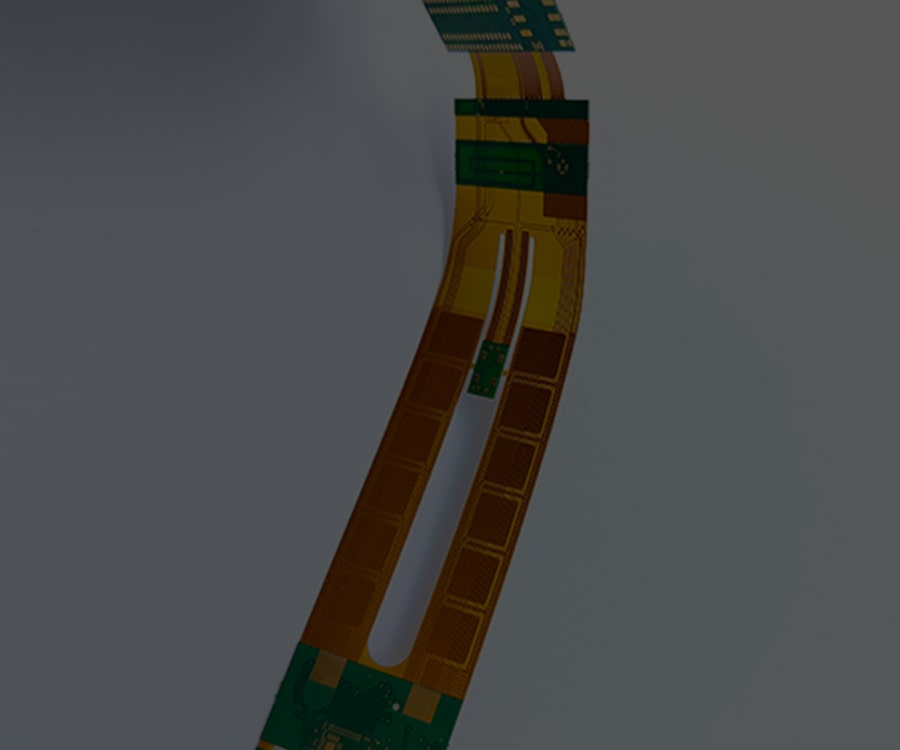

POE has specialized in bare rigid‑flex PCB and flexible PCB manufacturing since 2011, focusing on medium‑to‑small production runs with fast turnaround. Our capabilities cover design validation, stack‑up optimization, controlled impedance, and reliability for dynamic bend regions.

With a 3,000 m² electronics facility equipped for inspection and reliability testing (AOI, X‑ray, microsection, reliability bend testing), we deliver high‑quality bare rigid‑flex PCBs ready for your assembly line. Engage us for engineering reviews to reduce risk in flex‑to‑install zones and stiffener transitions.

Share your Gerber, stack‑up intent, and impedance targets—POE manufactures high‑reliability bare rigid‑flex PCBs for demanding applications. From tight bend radii and dynamic flex regions to dense interconnects, our process controls and materials expertise ensure consistent mechanical endurance and signal integrity across prototypes and production volumes.

POE complies with multiple international standards, including ISO9001:2015, ISO14001:2015, ISO13485:2016, REACH, RoHS, UL, and IPC. We are a reliable manufacturer of bare rigid‑flex PCBs with strict process controls and traceability.

ISO9001

ISO14001

ISO13485

REACH

IPC

SGS

RoHS

Global logistics (expedited options available)

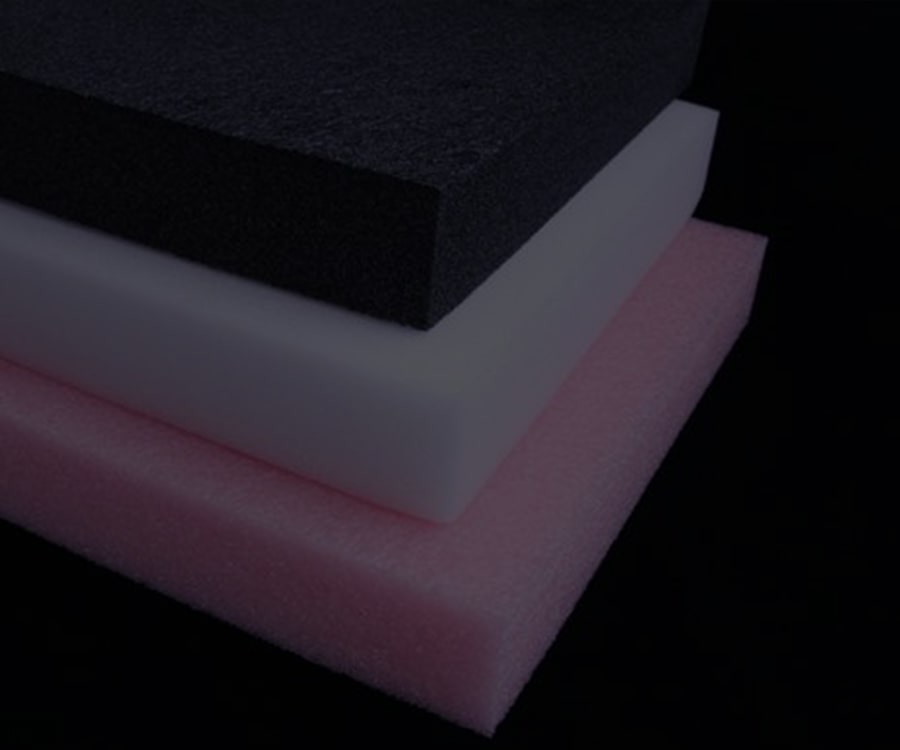

Rigid‑flex PCBs are packaged to protect flex tails, controlled‑bend zones, and exposed copper. Each lot is tracked by traveler ID, vacuum sealed with desiccant where required, cushioned with ESD‑safe materials, and boxed for safe transport. We ship worldwide with door‑to‑door service.

Send Gerber/requirements to

all@poe-pcba.com

Receive a tailored quote

within 24 hours

Confirm PO and specs

with our engineers

DFM for rigid‑flex & bend

zones; resolve EQ items

Start build; typical 5–7 days

depending on layer count

Scale to volume; 1–4 weeks

per quantity & complexity

Worldwide shipping

door‑to‑door

Receive boards; we provide

timely after‑sales support

Meet POE at global electronics exhibitions to discuss stack‑ups, materials, bend radius strategies, stiffener choices, impedance control, and reliability validation for your rigid‑flex projects. Bring your requirements—we’ll provide manufacturability insights and quick quoting.

Recent Rigid‑Flex Orders

| User Name | Date | QTY | Price |

|---|

NEWS & EVENTS

(2025) Rigid‑Flex Capability Expansion

POE has upgraded rigid‑flex imaging and lamination lines to support tighter registration and higher‑layer builds, improving yield and consistency for complex designs.

2025/01/12

Process Control for Flex Reliability

We refined bend‑zone copper handling and coverlay processes to enhance dynamic flex life and reduce risk in flex‑to‑install applications.

2024/12/25

Materials Library Updated

Added new PI cores, adhesive‑less options, and RA copper foils to better support high‑frequency and high‑reliability rigid‑flex designs.

2024/11/11

REQUEST A FREE CONSULTATION

Tell us your rigid‑flex requirements, target quantities, and constraints. Upload drawings or Gerber files—we’ll respond with a free quote and manufacturability feedback.

We stand behind our quality for all rigid‑flex PCBs.

24/7 After‑Sales Support.

We can sign an NDA before file transfer to protect your IP and design data.