Layers

Single-sided, double-sided, and multilayer (up to 40+ layers)

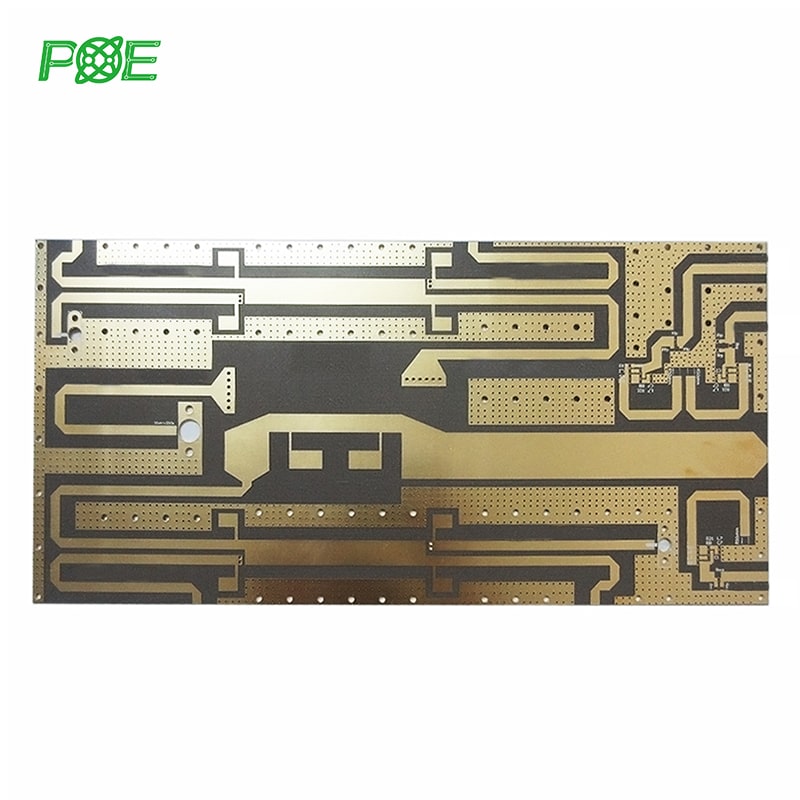

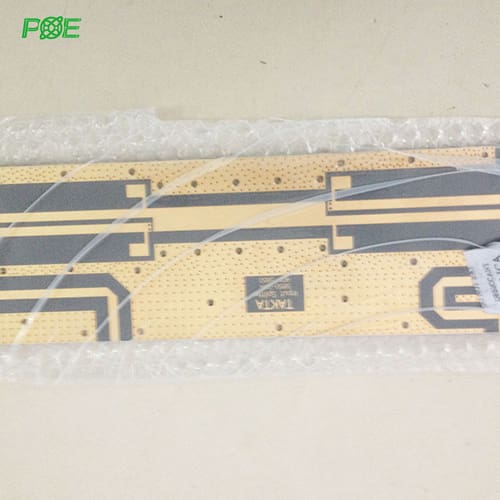

Material

High-performance RF materials: Taconic, Rogers, Isola, PTFE, Arlon, and FR-4 High-Tg

DK (Dielectric Constant)

2.0 to 10.0 (±0.05 tolerance for high-frequency applications)

DF (Dissipation Factor)

Low values, typically <0.005 for high-frequency applications, with ±0.0005 tolerance

Board Thickness

0.1mm – 6.0mm (±0.05mm tolerance)

Copper Thickness

0.5 Oz (17.5 μm) – 5 Oz (175 μm)

Minimum Trace Width/Spacing

3mil/3mil (0.0762mm/0.0762mm) or better, depending on design and materials

Minimum Hole Size

0.15mm (6mil) – 0.4mm (16mil) or larger, depending on layer count

Operating Frequency

DC to 40GHz, optimized for RF/microwave applications

Maximum Board Size

500mm x 1100mm (20" x 44") or larger, varies with layer counts

Surface Finish

ENIG (preferred for RF), Immersion Silver, OSP, HASL, Lead-Free HASL

Solder Mask

Green, Blue, Yellow, Black, Red, White, and other colors

Solder Mask Resolution

3mil (0.0762mm) minimum

Solder Mask Registration

±2mil (±0.0508mm)

Silkscreen Color

White, Black, Yellow

Plated Through Holes (PTH)

Yes, with controlled aspect ratio up to 10:1

Blind & Buried Vias (BBV)

Yes, with precise depth control for impedance matching

Controlled Impedance

Yes, ±5% tolerance for critical RF traces (50Ω, 75Ω, 100Ω, etc.)

Electrical Testing

Continuity & isolation, impedance control, Hi-Pot, S-parameter testing for RF performance

Thermal Management

Advanced solutions including thermal vias, embedded heat sinks, and metal cores for high-power RF applications

RF Performance Testing

Network analyzer testing, insertion loss measurement, VSWR verification

Certification

ISO9001:2015, ISO13485:2016, ROHS, UL 94V0, IPC-600G Class II and IPC-6012B Class II standard

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China