These examples represent just a fraction of our global collaborations. Due to non-disclosure agreements (NDAs) with many of our clients, we are unable to publicly share more exciting project details and success cases. We remain committed to the principles of integrity, quality, and service excellence, consistently providing reliable products and professional technical support to clients worldwide. We look forward to earning the trust of more customers and welcome inquiries for future partnership discussions!

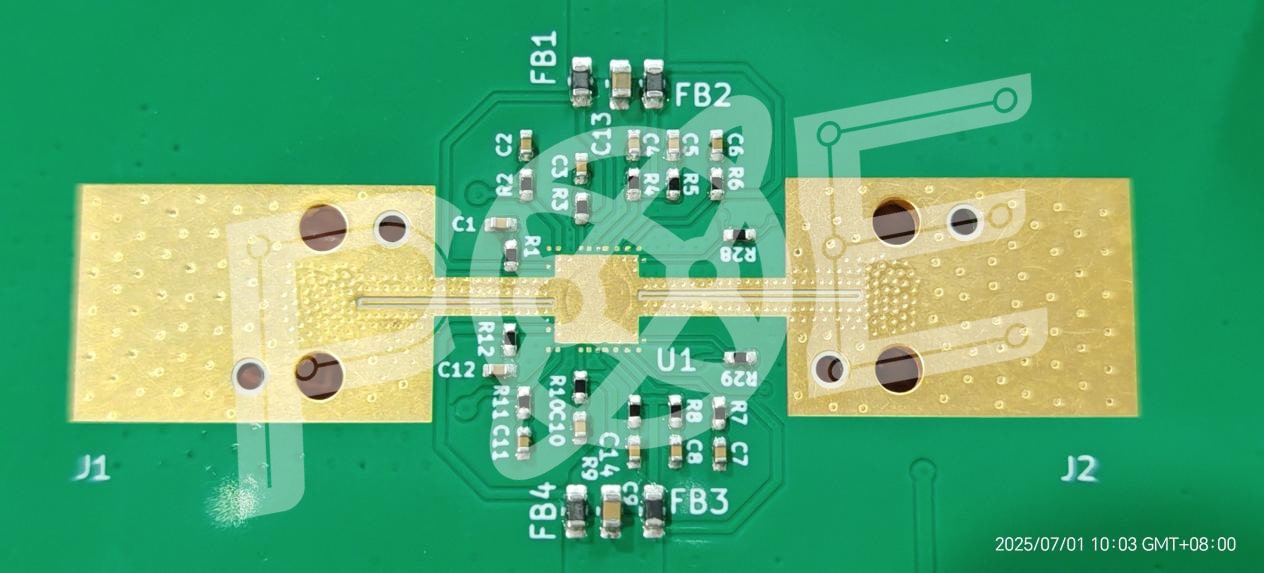

From bare PCB prototyping to PCBA sample production and planned bulk manufacturing transfer from Europe to China.

Industry: IoT

Scope of Cooperation:

- 2020: Bare PCB prototyping

- 2024: PCBA sample production

- 2025-2026: Plan to transfer bulk manufacturing from Europe to China

Core Requirements: Fast and on-time delivery, competitive pricing, quality assurance, service efficiency

2020: Bare PCB Prototyping

POE conducted comprehensive Design for Manufacturability (DFM) analysis, optimizing production designs to achieve rapid, high-quality delivery, planting the seed of trust with the client.

2024: PCBA Sample Production

The client began considering transferring PCBA production to China and partnered with POE for samples. POE delivered faster turnaround than existing suppliers, more competitive pricing, production anomaly resolution, and multi-stage quality inspections.

Bulk Production Cost Optimization

POE's superior supply chain management reduced the client's BOM material costs by 15%.

Compliance & Standards

POE's production adheres to ISO 9001, ISO 13485:2016, and UL standards, ensuring full compliance with international quality and environmental requirements.

"Working with POE has been a game-changer for our production process. Their attention to detail and commitment to quality have exceeded our expectations."

PCBA prototyping and mass production, cable assembly, functional testing for smart home and green energy solutions.

Country: United Kingdom

Industry: Smart Home & Green Energy (Smart Ventilation Systems)

Scope of Cooperation: PCBA prototyping and mass production, cable assembly, functional testing

Order Scale: From initial 5 prototype sets to expanded mass production of 50,000 units (2025)

Key Requirements: Competitive pricing, rapid delivery, high-quality assurance

Prototyping Excellence

- Provided multiple high quality prototypes since 2019 with fast delivery

- Conducted comprehensive DFM analysis to optimize design for manufacturability

- Identified and resolved multiple production anomalies during prototyping phase

Optimization Expertise

- Recommended and validated 15+ alternative components through rigorous testing and compatibility analysis, achieving 15% BOM cost reduction

- Implemented lean manufacturing techniques that improved production efficiency by 20%

- Developed customized functional test fixtures that significantly reduced defect rates in mass production

- Inventory Management: Implemented advanced material preparation for critical components to ensure stable production continuity

- Production Flexibility: Established flexible manufacturing schedules to accommodate client's urgent orders and special requirements

Certifications & Compliance: Fully compliant with ISO 9001, ISO 13485:2016, UL, RoHS, and REACH standards

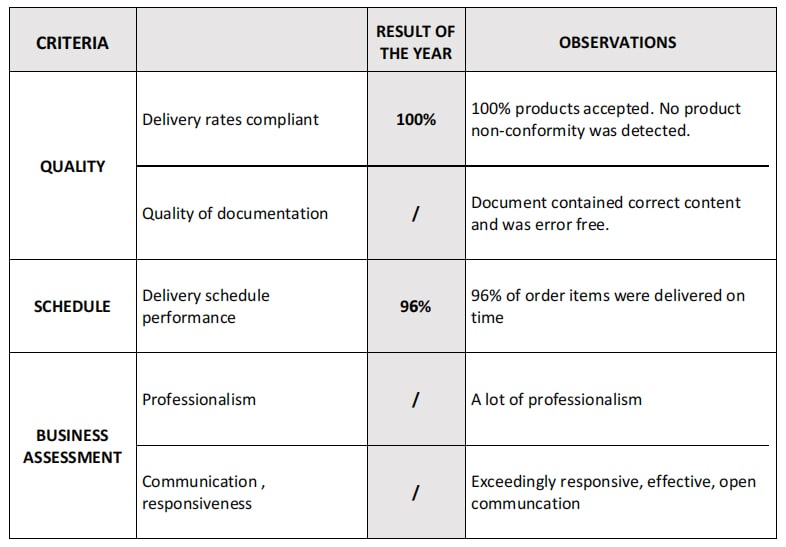

Quality Metrics:

- 99.2% on-time delivery rate

- 99.5% product quality acceptance rate

- 24-hour response time for quality issues

- Cooperation Duration: 5+ years

- Cumulative Delivery: 500,000+ units

- Scale Up: 300% production capacity expansion in 2025

"POE's comprehensive solution significantly enhanced our supply chain efficiency. Their rapid prototyping capabilities accelerated our product development timeline, while their continuous optimization efforts delivered substantial cost reductions. Throughout our collaboration, they maintained exceptional quality standards and demonstrated remarkable flexibility in meeting our evolving requirements. A reliable partner that consistently exceeds expectations."

--- Director of Supply Chain, Richard

High-precision wearable sensor PCBs for medical device manufacturers, compliant with FDA and ISO 13485 standards.

| Element | Details |

|---|---|

| Customer's Country/Region | Canada |

| Cooperation Period | February 2020 - Present |

| Customer's Sub-field | Wearable Diagnostic Equipment, Wireless Testing Equipment |

| Type of Cooperative Products | Clinical Monitoring Sensor PCBA Components |

| Scale of Cooperation | 50 sets of PCBA boards for the first order, and the subsequent quarterly repeat purchase volume is stably between 1000 - 5000 sets |

The customer is a venture capital-backed startup that develops and commercializes wearable sensors to improve the clinical management of critically ill patients both inside and outside hospitals. It provides real-time functional hemodynamic monitoring for patients in need of cardiopulmonary and fluid resuscitation.

Key requirements before cooperation:

- The customer's products are small in size and relatively precise

- The designed prototype is a rigid-flexible combined PCBA multi-layer board with blind and buried vias and impedance requirements

- The customer requires a one-stop service, which includes programming testing, barcode generation, tracking of test results for each board, after-sales service, etc.

- The customer also requires passing strict third-party factory audits

- Complete technical data: Detailed PCB stack-up data, impedance requirements, reinforcement thickness, etc.

- Production environment and certification requirements: ESD protection throughout production, ISO13485 requirement, compliance reports for ISO9001, UL, RoHS 2.0, and REACH

- Delivery time and quality assurance: All components must be original to ensure a service life of at least 5 years; production status updated in real time

- Hardware facilities: Sufficient production lines and machines to meet order requirements

- Production lines equipped with high-precision placement machines, multiple AOI systems, X-Ray inspection equipment, FAI tools, SPI devices

- Experienced QC team ensures product quality 24 hours a day

- Flexible production plans tailored to customer's delivery time and quality requirements

- Professional team of engineers and business team provide satisfactory responses within 1-24 hours

- Customer can communicate with POE face-to-face via phone or video conference

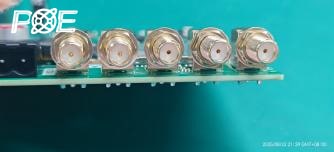

Rapid, end-to-end PCBA solutions for a US IoT pet door startup recovering from a 3-month engineering delay.

| Item | Details |

|---|---|

| Country | The United States |

| Industry | IoT (Smart Pet Door) |

| Cooperation Scope | PCBA, Cable Assembly, Conformal Coating, and Functional Testing |

| Order Scale | 10-unit prototype → 1,000-5,000-unit bulk orders (2025 expansion) |

| Critical Need | Fast, high-quality delivery to recover from a 3-month engineering delay |

Prototype: Hitting the CES Deadline

The customer's top priority was getting 10 prototype PCBAs ready for the CES trade show—a make-or-break opportunity to showcase their smart pet door to investors and buyers. POE streamlined production, prioritized their order, and delivered the 10 prototypes on time. The customer not only exhibited at CES successfully but also gained valuable market feedback.

Bulk Production: Scaling with Confidence

By March 2025, the customer was ready to scale. POE supported their 5,000-unit bulk order, ensuring every step aligned with their goals. The result was a 99.5% pass rate—far exceeding the customer's expectations.

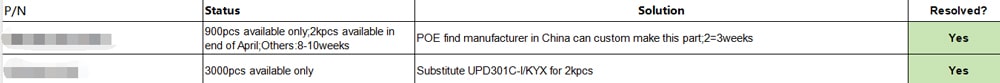

Component Shortages & Shifting Production Needs

POE leveraged its global supply chain network to source hard-to-find parts. For components with limited stock, POE either partnered with manufacturers for custom production or recommended approved substitutes to avoid delays.

Last-Minute Design Changes

POE proactively suggested assembling 5 test prototypes before full bulk production. When the customer needed firmware and hardware updates, these prototypes allowed validation of changes without scrapping entire batches, saving weeks of rework and thousands in costs.

Specialized Packaging for Odd-Shaped PCBs

The customer's uniquely shaped "toothpick-like" PCBs required custom bubble-lined cartons tailored to the PCB shape, ensuring safe transit while optimizing space and reducing shipping expenses.

Costly Import Taxes

POE simplified logistics by offering DDP (Delivered Duty Paid) terms, covering all customs clearance and taxes, allowing the customer to avoid unexpected costs and enjoy a hassle-free delivery process.

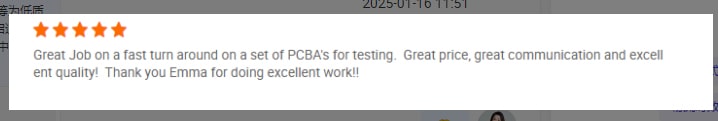

"Great job on the fast turnaround for our PCBA testing! Great price, great communication, and excellent quality—thank you for doing such excellent work!!"

One-stop PCBA services for a leading American fire alarm and life safety technology company.

The client is a leading American security products manufacturer dedicated to advancing fire alarm and life safety technologies. It provides innovative and reliable solutions to protect people, property, and communities across the nation.

| Aspect | Details |

|---|---|

| Country | United States |

| Industry | Security Products (Fire Alarms) |

| Scope of Cooperation | PCBA Manufacturing |

| Order Volume | 100,000 pieces per year |

| Core Requirements | One-stop PCBA services, product certification, price sensitivity |

1. This PCBA project uses only through-hole components, requiring sufficient DIP production lines and an adequate number of hand-soldering operators.

2. Assist the customer with UL certification for their products.

3. Support the customer in sourcing high-quality yet low-cost alternative components in China (e.g., connectors, resistors, capacitors, heat shrink tubing, etc.).

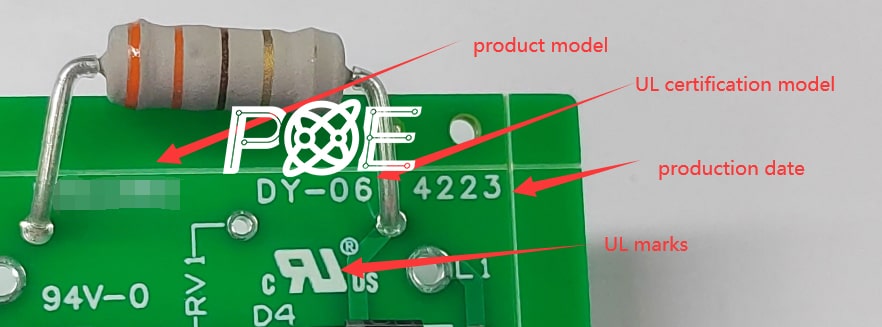

4. Assist the customer in modifying Gerber designs, optimizing panel layouts, and adding silkscreen information including UL certification model, UL mark, production date, and product model.

Hardware Facilities: Possess sufficient DIP production lines, wave soldering equipment, and a team of professional and stable hand-soldering operators to meet customer order requirements.

On-Time Delivery: Maintain timely communication with the customer and develop flexible production plans tailored to their delivery schedule.

Product UL Certification: Provide end-to-end support for the customer's UL certification process, including assisting and accompanying UL auditors during factory inspections. Help the customer establish long-term compliance mechanisms to ensure ongoing certification validity and stable market access.

Component Substitution Solution: Source high-quality, cost-effective alternative components in the Chinese market based on the customer's BOM and pricing requirements, meeting both quality and cost targets.

Gerber Design Modification: PCB designers assist the customer in optimizing Gerber panelization and adding required silkscreen information, such as UL certification model, UL mark, production date, and product model, to meet certification and production needs.

Advanced PCBA solutions for generalist superhumanoid robots capable of performing all core warehouse tasks.

| Element | Details |

|---|---|

| Customer's Country/Region | USA |

| Cooperation Period | February 2022 - Present |

| Customer's Sub-field | Warehouse Robotics |

| Scale of Cooperation | 5 sets of PCBA boards for the first order, and subsequent quarterly repeat purchase volume is stable at 80 sets of robots |

The intelligent general-purpose warehouse robot is the world's first robot capable of performing all core warehouse tasks, including storage, retrieval, picking, packing, and sorting. Our proprietary robot replaces dozens of complex systems, enabling autonomous warehouse operation at a fraction of the cost and complexity of today's mainstream systems.

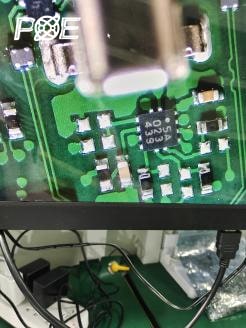

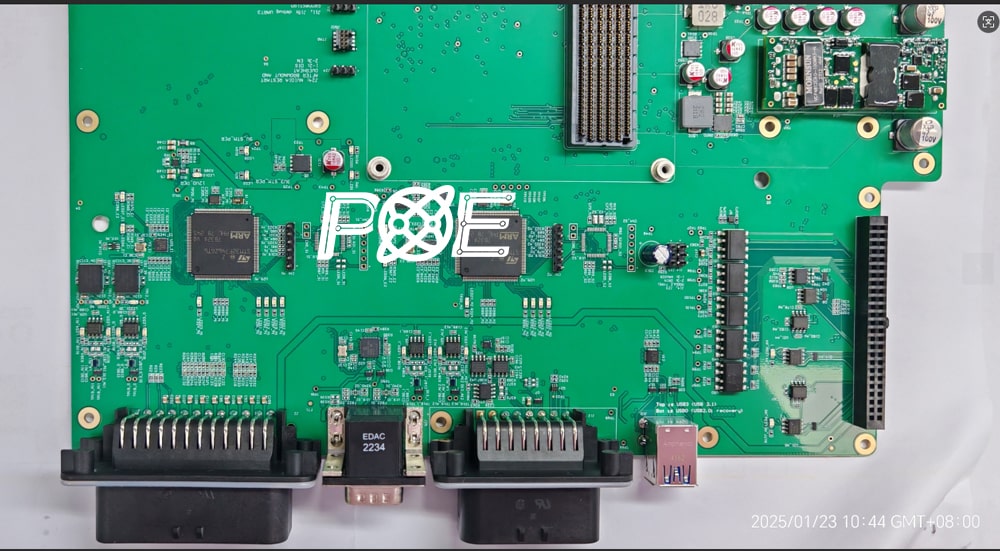

High-Precision Case: High TG 8-Layer Board

Advanced Processes: Impedance Control; Resin Filling Plated Through Holes

Industry Application: Generalist Superhumanoid Robots

The main challenges faced in PCBA production were efficiency bottlenecks, quality fluctuations, high labor costs; and difficulties with specific processes.

- One-on-one efficient and rapid response, fast quotation

- 100% original components, guaranteeing quality

- Fast delivery requirements, all production typically delivered within 1 month

- Flexibility in handling minor processing changes during production

- Functional Circuit Testing (FCT) performed on all PCBA boards

Supplier Experience & Service: Possesses extensive experience and successful cases in the PCBA robotics field, offering more tailored professional solutions and reliable technical support.

Precision Placement: High-precision SMT robots are the core of the SMT production line. They utilize multi-axis coordination and vision systems to accurately place miniature components onto predetermined PCB positions, far exceeding manual capabilities in both speed and accuracy.

Quality Inspection & Testing: Automated Optical Inspection (AOI), X-Ray inspection, and Functional Circuit Testing (FCT) significantly enhance inspection efficiency and accuracy.

Precision Coating & Dispensing: Accurate application of conformal coating, thermal paste, etc., to protect circuit boards and improve reliability.

High-reliability PCBA for aerospace data recording systems operating in harsh environments.

| Element | Details |

|---|---|

| Customer's Country/Region | France |

| Cooperation Period | July 2014 - Present |

| Customer's Sub-field | Data Recorders |

| Scale of Cooperation | Primarily samples, hundreds of models ordered annually with extremely high repurchase rate |

High-Precision Case: High TG 16-Layer Board

Advanced Processes: High Layer Count, BGA, Gold Fingers

Industry Application: Aerospace Data Recorder

With 46 years of experience in the acquisition/recording system industry, the client is the leader in the field of signal acquisition in harsh environments and provides acquisition and recording system solutions.

Clear Requirements & Pain Points:

- Wide variety of models, low quantity required per model

- High order frequency, requiring flexible cooperation

- All PCBA boards incorporate BGAs, requiring high-quality soldering and guaranteed quality

POE has No MOQ (Minimum Order Quantity). Required quantities per order are typically only 1-20 PCS. The boards are complex with many component types. POE generally provides a quotation within 2-3 hours of receiving an inquiry; orders are placed the next day, with delivery in 20-25 calendar days.

Process Capability:

- Possesses manufacturing processes for high multilayer boards (18+ layers), HDI, heavy copper, rigid-flex

- Uses nitrogen reflow soldering, greatly improving soldering quality

Inspection & Testing Capabilities:

- Equipped with AOI (Automated Optical Inspection), X-Ray (for inspecting BGA solder joints), visual inspection, flying probe test, and other full-process inspection equipment

Quality System & Traceability:

- Establishes a full-process quality traceability system from material receiving, production process, to product shipment

- Can trace the source, batch, etc., of every component

- Provides corresponding material traceability reports, PCB inspection reports, etc., with each shipment

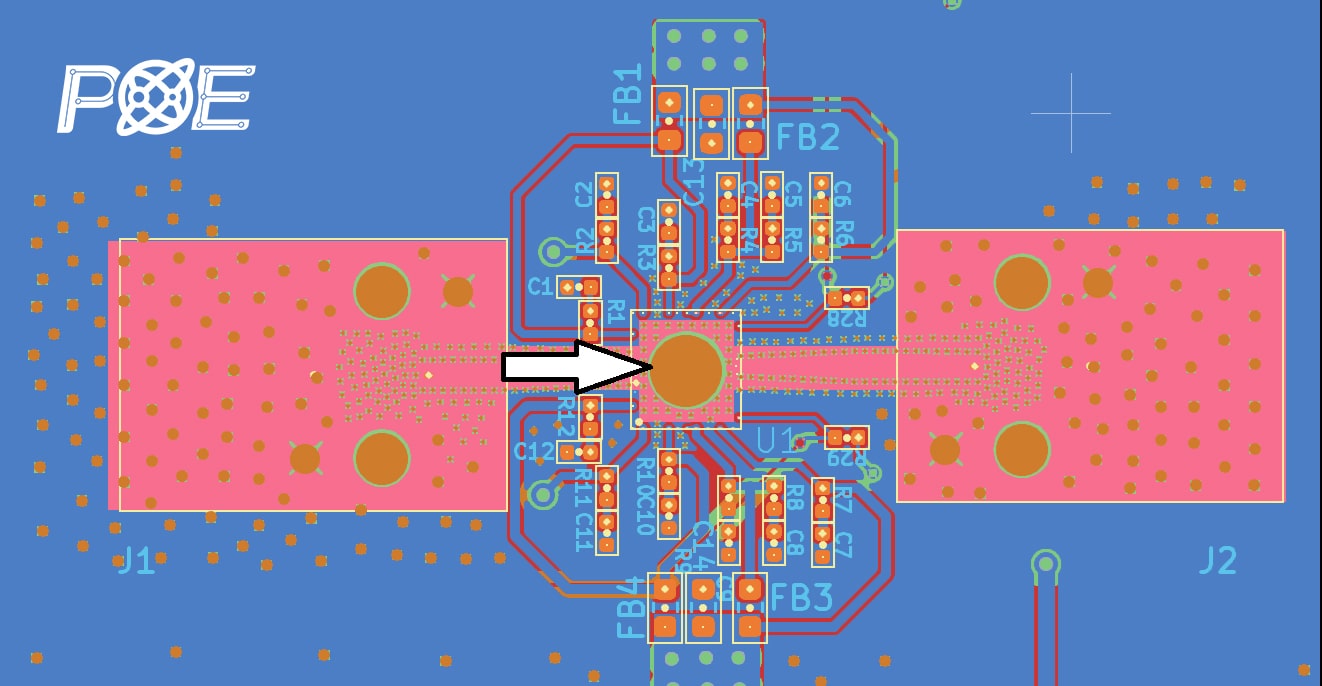

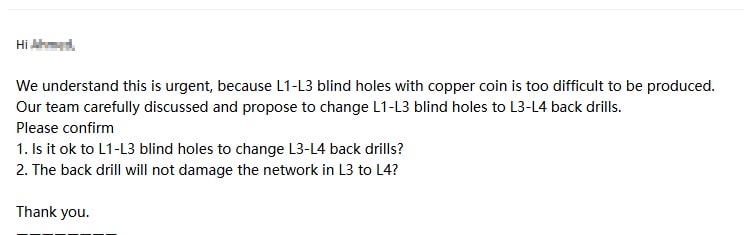

Specialized PCB manufacturing with embedded copper coins for advanced research applications.

In the field of high-end precision manufacturing, customers' requirements for specialized processes often reflect the deep integration of cutting-edge research and innovative design. Recently, we undertook a highly challenging task: a customer from the renowned University of Waterloo explicitly required the precise embedding of 3mm diameter copper coins at specific plated hole locations. This unique structure placed extremely high demands on the feasibility, precision control, and reliability of the circuit board manufacturing process.

Customer's Core Challenge: This specialized process exceeded the conventional production capabilities of most PCB manufacturers, presenting significant technical hurdles in positioning accuracy, material integration, and electrical interconnection reliability.

Based on the customer's requirements, POE quickly assembled a dedicated technical team and developed a systematic customized solution leveraging years of experience in specialized processes and an advanced material system:

1. Innovative Material Combination: PTFE+FR4 Hybrid Lamination

A PTFE+FR4 hybrid laminate was used to create the embedded copper coin board, employing a core+core structure. This design perfectly accommodated the embedding requirements of the copper coins, ensuring the overall stability of the board while providing a solid foundation for the coins, effectively preventing loosening or detachment during subsequent production and use.

2. Professional Recommendations for Specialized Holes

POE's technical team provided expert recommendations for the specialized holes in the project. The machining precision of these holes directly impacted the performance and quality of the entire circuit board. We conducted comprehensive evaluations of hole positioning, dimensional tolerance control, and fit clearance with the copper coins. By optimizing the machining process and utilizing high-precision equipment, we ensured that all parameters of the specialized holes strictly met design standards, providing reliable assurance for the successful embedding of the copper coins and the subsequent hole plating process.

POE has always positioned itself as a "scientific-grade manufacturing partner," focusing on collaborative innovation and offering a highly flexible, responsive, and technically supportive service system:

Deep Technical Expertise and Engineering Excellence: Capable of understanding complex requirements and providing professional advice on design, process, and materials; mastering and investing in advanced processes.

Ultimate Production Flexibility: Supports seamless production from single prototypes to small and medium batches, with no minimum order quantity (MOQ) restrictions, making it ideal for research prototypes, pre-development projects, and multi-iteration needs.

Efficient Responsiveness: Dedicated project management and technical representatives ensure quick responses to customer inquiries, maintaining clear and transparent project progress.

Collaborative and Win-Win Mindset: Understanding the value of research, we are committed to building long-term strategic partnerships with academic institutions rather than pursuing short-term profits.