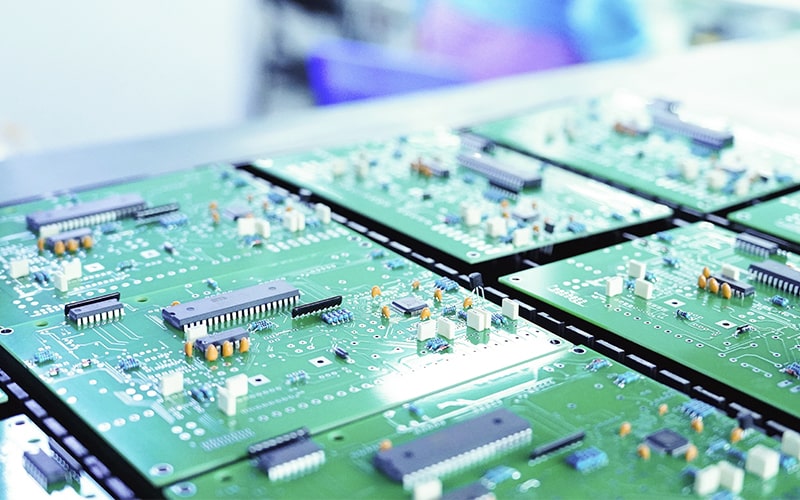

Professional PCB assembly services tailored for small to medium production runs with industry-leading 99.8% quality pass rate. From 1 to 5,000 units with turnaround as fast as 48 hours.

Get a Quote Today48-hour express service available for urgent projects. Standard 5-7 day turnaround for regular orders. We understand time-to-market is critical for your business.

99.8% first-pass yield rate. 100% AOI inspection and X-ray testing for BGA components. IPC-A-610 Class 2 & 3 standards compliance for critical applications.

Up to 30% lower costs compared to high-volume manufacturers. No minimum order quantity. Transparent pricing with no hidden fees. Volume discounts starting at 100 units.

Pick-and-place machine with ±0.025mm placement accuracy. Reflow soldering with 10-zone temperature control. Wave soldering capability for through-hole components.

15+ years average experience of our engineering team. Free DFM review within 24 hours. Dedicated project manager for each order. Technical support available via phone, email, and live chat.

From single prototype to 5,000+ units per order. Scalable production capacity of up to 50,000 components per day. Ability to handle both simple and complex multi-layer boards up to 40 layers.

Our engineers review your design files and provide DFM feedback within 24 hours to ensure manufacturability and optimize yield.

We source components from authorized distributors with full traceability or use your provided materials with proper handling procedures.

Precision placement of surface mount components using automated pick-and-place machines with ±0.025mm accuracy and 10-zone reflow soldering.

Manual or wave soldering insertion of through-hole components with IPC-A-610 Class 2/3 workmanship standards for maximum reliability.

100% AOI inspection, X-ray for BGA/QFN, functional testing, and final QC inspection with detailed reports before shipping.

Challenge: Needed 500 complex 10-layer medical device PCBs with 0.5mm BGA components within 2 weeks for FDA submission.

Challenge: Required 1,000 power supply boards with 0201 components and rapid 7day turnaround for a smart city pilot project.

Whether you need a single prototype or a production run of 5,000 units, our team is ready to deliver high-quality PCB assembly services tailored to your specific requirements.

Free DFM Review

No Minimum Order

48-Hour Express Option

99.8% Quality Rate

Reflow defects rarely look dramatic — they look “almost fine.” ⚠

— POE PCB/PCBA Manufacturer (@poe_pcba) February 2, 2026

That’s why they’re expensive.

If your failures are intermittent and hard to reproduce, DM me your board size + copper distribution + key packages — I’ll send a quick screening checklist for reflow margin risk. pic.twitter.com/9YsQUj8uNq

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China