Layers

1-40+ layers (High-density multilayer capability for complex robotics control systems)

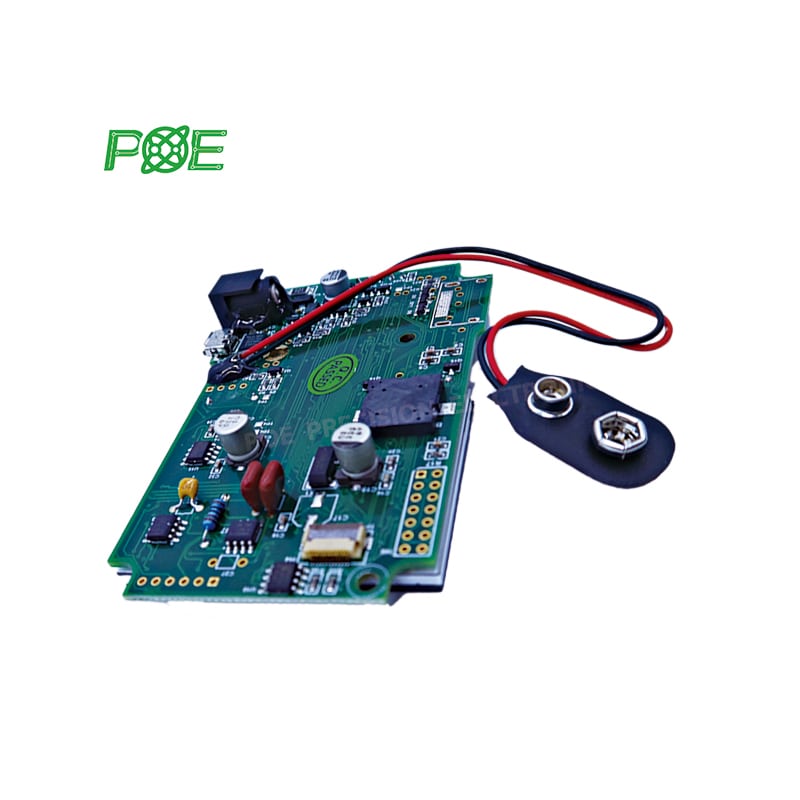

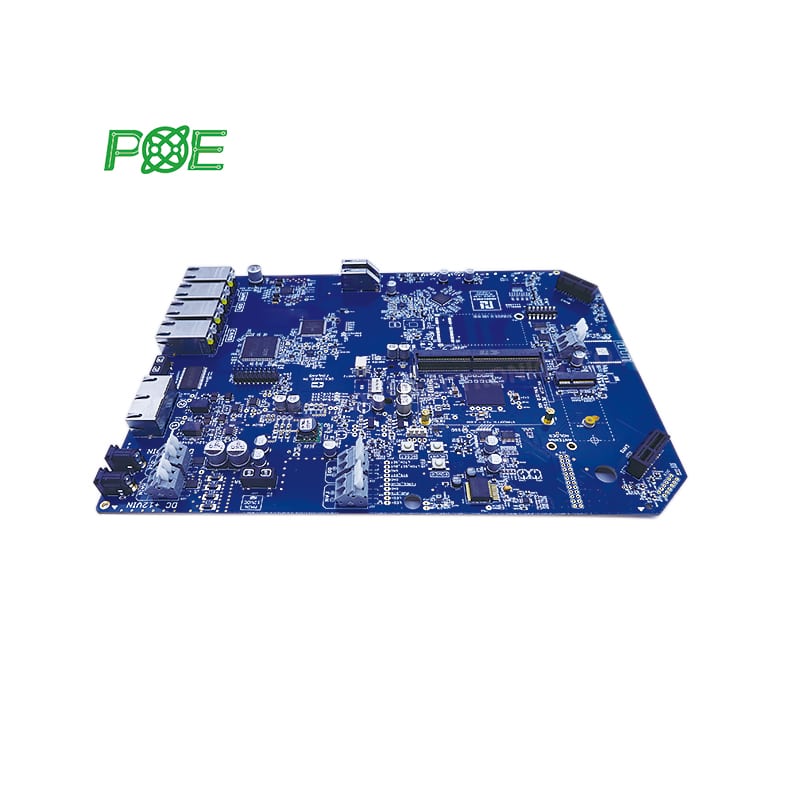

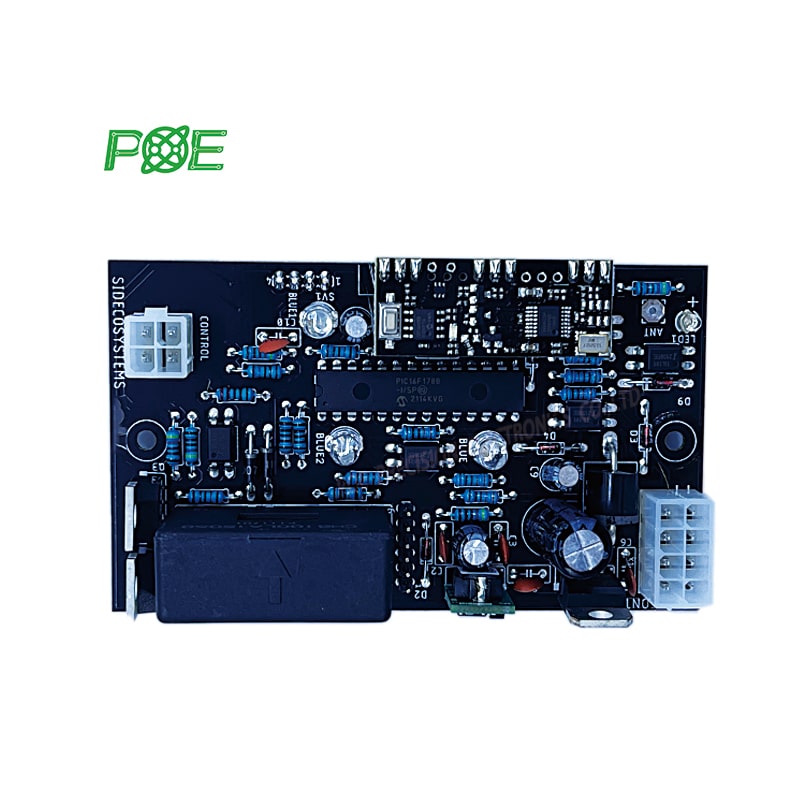

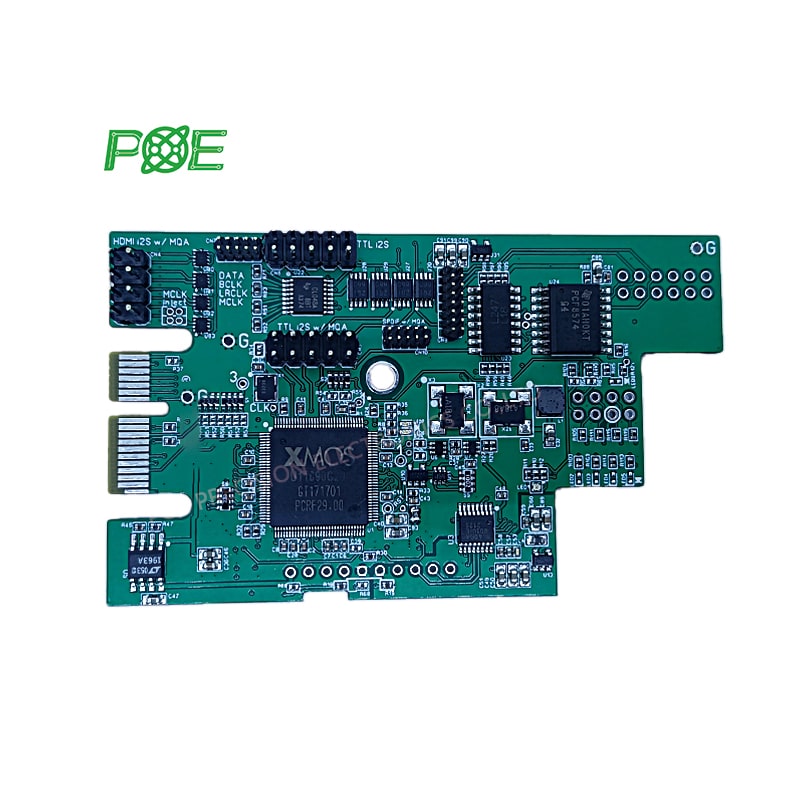

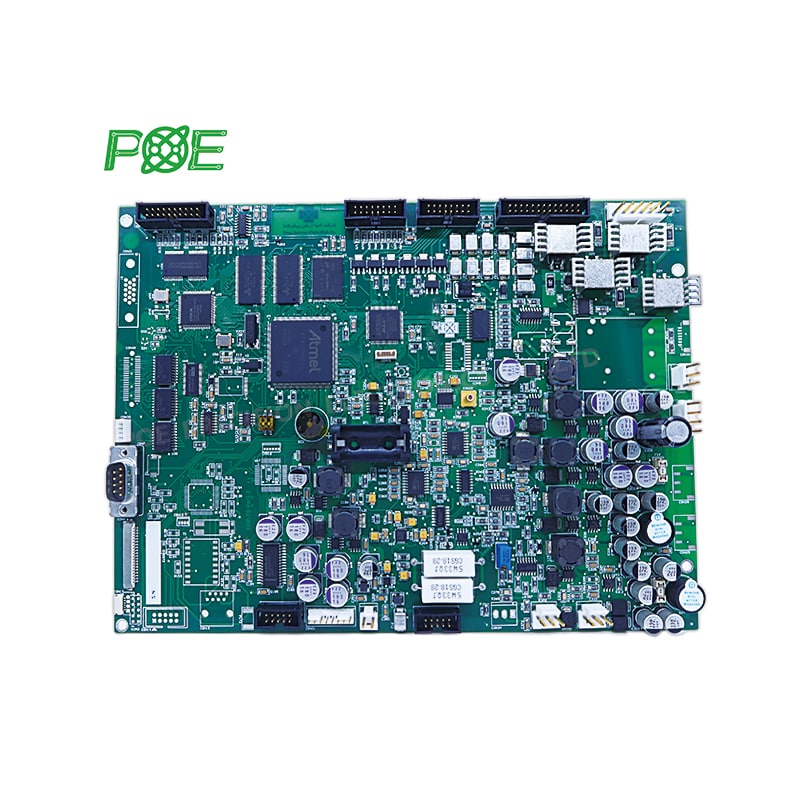

Assembly Type

Through-Hole (THT), Surface Mount (SMT), Mixed (THT+SMT), Advanced Package-on-Package

Minimum Component Size

01005 or 0201 (Imperial) / 0402 or 0603 (Metric) - Essential for miniaturized robotics applications

Maximum Component Size

2.0 in x 2.0 in x 0.4 in (50 mm x 50 mm x 10 mm) - Accommodating larger power components

Component Package Types

BGA, QFN, QFP, SOIC, SOP, SSOP, TSSOP, PLCC, DIP, specialized robotics modules

Minimum Pad Pitch

0.4 mm (16 mil) for QFP/QFN, 0.5 mm (20 mil) for BGA - Supporting high-density robotics controllers

Minimum Trace Width

0.10 mm (4 mil) - Precision manufacturing for complex routing in motion control systems

Minimum Trace Spacing

0.10 mm (4 mil) - Enabling high-density interconnects for sensor arrays

Minimum Drill Size

0.15 mm (6 mil) - Precision micro-vias for multi-layer robotics PCBs

Maximum Board Size

18 in x 24 in (457 mm x 610 mm) - Suitable for industrial robotics control panels

Maximum Board Thickness

0.062 in (1.6 mm) to 0.125 in (3.2 mm) - Optimized for robotics applications

Board Material

FR-4, High-Tg FR-4, Aluminum (for thermal management), Flexible(FPC for moving parts), Rigid-Flex (for articulated joints)

Surface Finish

ENIG (for fine-pitch components), HASL, Gold Finger (for edge connectors), OSP, Immersion Silver

Solder Paste Type

Leaded or Lead-Free (RoHS compliant) - High-reliability formulations for robotics applications

Assembly Process

Advanced Reflow Soldering, Selective Wave Soldering, Precision Hand Soldering for specialized components

Inspection Methods

Automated Optical Inspection (AOI), X-ray (AXI) for BGA inspection, 3D Solder Paste Inspection (SPI)

Testing Methods

In-Circuit Test (ICT), Functional Test (FCT), Flying probe test, Motor driver and sensor validation

Design for Manufacturing (DFM)

Comprehensive DFM Analysis and Expert Feedback, Design Optimization for robotics applications

Turnaround Time

Prototype: 24 hours to 7 days, Production: 10 days to 4 weeks - Expedited services available

Robotics-Specific Capabilities

Motor driver circuits, sensor integration, power management systems, embedded controller assembly

Certifications & Standards

ISO9001:2015, ISO13485:2016, ROHS, UL 94V0, IPC-A-600G Class II/III, IPC-6012B Class II/III

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China