POE specializes in advanced conformal coating solutions and brings years of expertise in protecting, inspecting, and delivering high-quality PCB assemblies. We make environmental protection simple and reliable:

Protect your PCBs from harsh environments with POE’s professional conformal coating services.

Our advanced solutions shield electronic assemblies from moisture, dust, chemicals, and extreme temperatures—extending product lifespan and reliability.

We offer a full range of coating technologies, including acrylic, silicone, urethane, and parylene, tailored to meet diverse environmental demands and industry standards. With precise application and rigorous quality control, our team ensures optimal protection for your critical electronic components.

POE offers comprehensive conformal coating solutions designed to protect your PCBs from harsh environmental conditions. Our advanced coating technologies and precise application methods ensure maximum protection and reliability for your electronic assemblies across various industries and applications.

Fast-curing, easy to repair, excellent moisture protection

Superior temperature resistance and flexibility

Outstanding chemical and abrasion resistance

Ultra-thin, pinhole-free barrier protection

Precise application avoiding connectors and test points

Comprehensive inspection and validation services

POE provides a comprehensive one-stop solution for conformal coating services.

POE delivers industry-leading conformal coating services with state-of-the-art equipment and rigorous quality control processes. Our experienced technicians ensure precise application, optimal coverage, and consistent results that meet or exceed industry standards for environmental protection and reliability.

Extended PCB Lifespan & Enhanced Reliability

Our specialized conformal coatings create a protective barrier that shields your PCBs from moisture, dust, chemicals, and temperature fluctuations. This protection significantly extends component life, reduces failure rates, and ensures consistent performance in challenging environments.

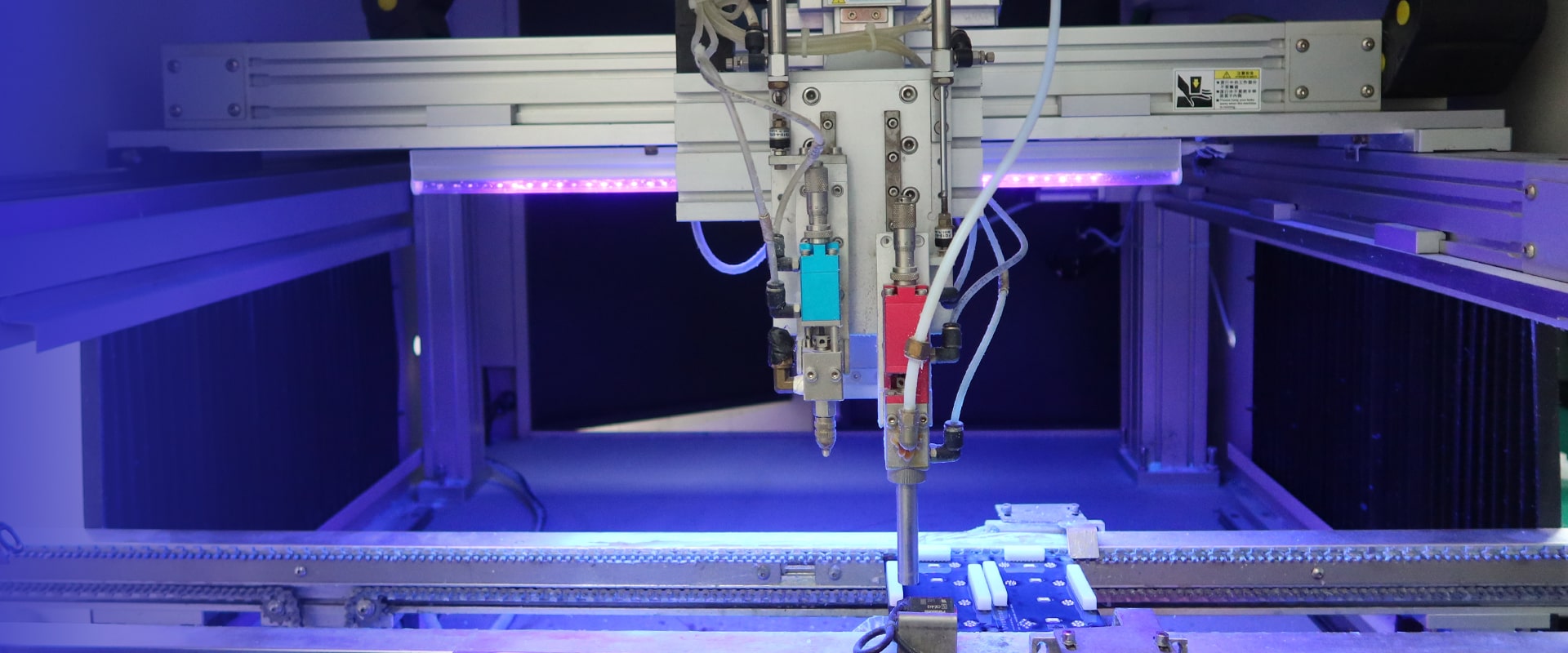

Advanced Application Technology & Precision Control

We utilize state-of-the-art selective coating equipment and automated dispensing systems to ensure precise application. Our advanced masking techniques protect connectors and test points while achieving uniform coverage on critical areas, guaranteeing optimal protection without compromising functionality.

Industry Certifications & Quality Standards

Our conformal coating processes comply with IPC-CC-830 standards and are certified under ISO 9001:2015, ISO 13485:2016, REACH, and RoHS regulations. We maintain strict quality control protocols including thickness measurement, adhesion testing, and visual inspection to ensure consistent, reliable results.

REQUEST A FREE CONSULTATION

Fill in the form with vour requirements and ouantity unloan the relevant documents and we will provide you with a free quote right away!

For All Products Purchased From Us, If You Encounter Any Quality:

Offer "24/7 After-sales Support".

Before sending us the files, you can sign a NDA with us to ensure you can choose us with complete confidence.

Reflow defects rarely look dramatic — they look “almost fine.” ⚠

— POE PCB/PCBA Manufacturer (@poe_pcba) February 2, 2026

That’s why they’re expensive.

If your failures are intermittent and hard to reproduce, DM me your board size + copper distribution + key packages — I’ll send a quick screening checklist for reflow margin risk. pic.twitter.com/9YsQUj8uNq

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China