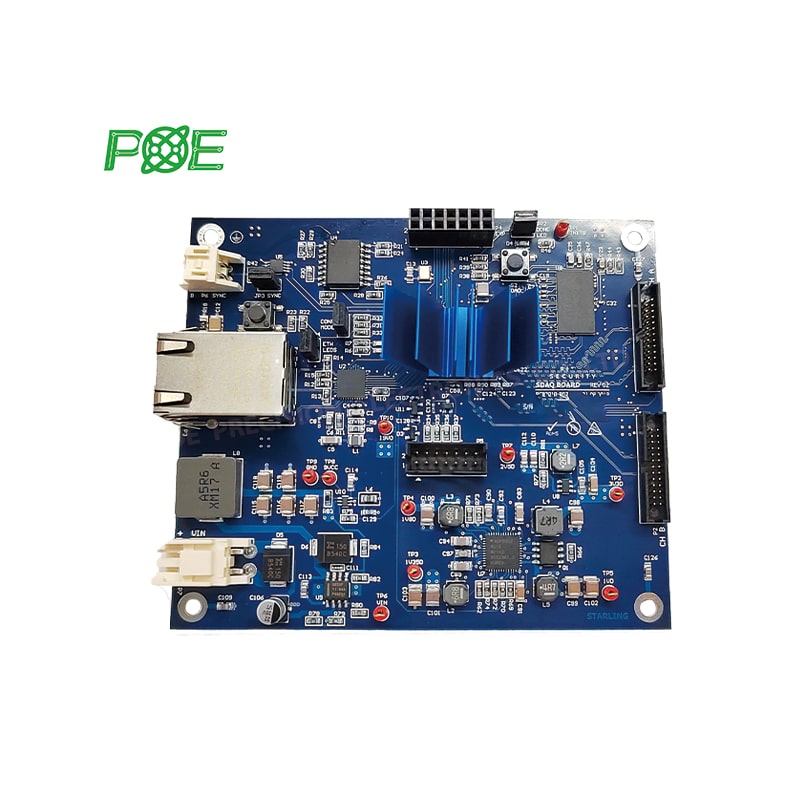

End-of-year rhythm at POE: shipments going out every day

— POE PCB/PCBA Manufacturer (@poe_pcba) February 10, 2026

Labels on. Checks done. Tracking sent.

Fast builds are one thing — shipping on the promised day is the real discipline.

If your deadline is tight, send the Gerber + BOM. We’ll tell you what’s realistic.#PCBA pic.twitter.com/wlnqPCGIpY

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China