Providing high-reliability, high-precision PCB manufacturing and assembly services for the global electric vehicle charging industry, meeting the most stringent standards and certification requirements.

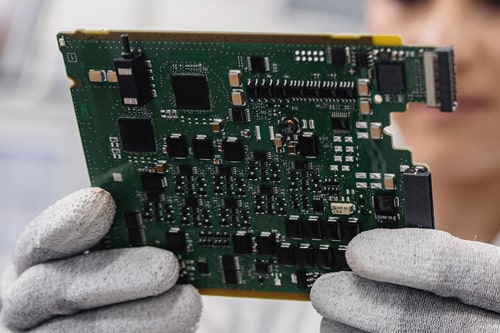

We understand the EV charging industry's strict requirements for safety, reliability, and durability. Our expert team and advanced facilities ensure every project meets the highest standards.

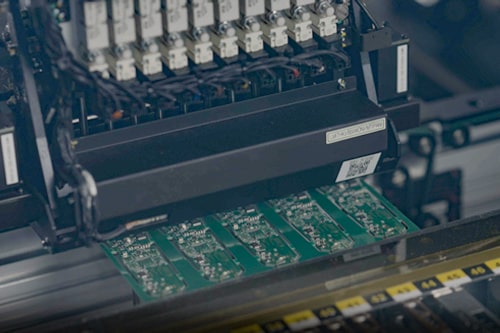

As a trusted partner in the EV charging industry, we provide comprehensive support from prototype to mass production, ensuring the highest quality outcomes at every stage of your project.

Our specialized team has extensive industry experience, understanding and meeting the unique requirements of the EV charging sector to provide you with the most reliable PCB manufacturing and assembly solutions.

Our specialized technical capabilities meet the specific requirements of the EV charging industry, ensuring the highest quality outcomes for your charging infrastructure projects.

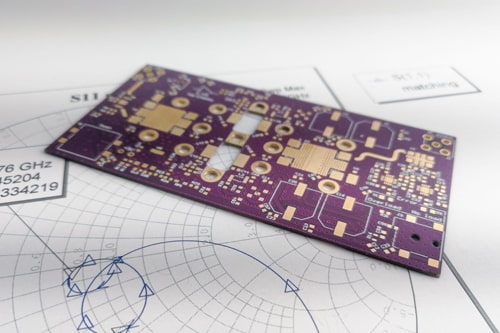

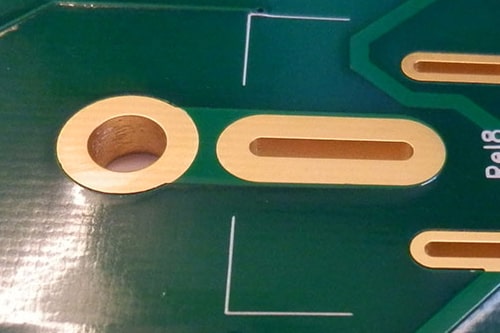

Our high power PCB technology supports thick copper, heavy current designs, and thermal management solutions essential for efficient and reliable EV charging systems.

Specialized manufacturing of power conversion PCBs for AC/DC and DC/DC conversion, ensuring efficient and reliable power delivery in EV charging applications.

Our communication PCB technology provides reliable connectivity solutions for smart charging systems with various protocol support including OCPP, Wi-Fi, and cellular.

Specialized manufacturing of PCBs for safety monitoring and control systems in EV chargers, ensuring protection against overcurrent, overvoltage, and thermal issues.

Our assembly services comply with IPC standards, ensuring reliability and durability for EV charging equipment in various environmental conditions.

Providing protective conformal coating and encapsulation services for outdoor EV charging equipment, ensuring long-term reliability in all weather conditions.

Our manufacturing processes and facilities meet international standards and certifications, ensuring the highest quality and reliability for your EV charger PCB projects.

Explore how our PCB manufacturing and assembly solutions have helped EV charging innovators bring their charging infrastructure to market.

Beyond PCB manufacturing and assembly, we offer a range of complementary services to support your EV charging product development journey.

Protective coating services to shield EV charging electronics from moisture, dust, chemicals, and temperature extremes, extending product lifespan.

Complete turnkey assembly services from PCB to finished product, including enclosures, cabling, and final testing for EV charging equipment.

End-to-end supply chain management and global shipping solutions to ensure your EV charging products reach their destination efficiently.

Custom cable assembly and wiring harness manufacturing for EV charging connectivity, power distribution, and vehicle interfaces.

Device programming, functional testing, and quality assurance services to ensure your EV charging products perform safely and reliably.

Design for Manufacturing and Assembly optimization to improve producibility, reduce costs, and enhance reliability of your EV charging devices.

Hear from EV charging innovators who have partnered with us for their PCB manufacturing and assembly needs.

Their expertise in high-power PCB manufacturing was crucial for our DC fast charging stations. The quality and reliability of their work exceeded our expectations.

We've been working with them for our commercial EV charger production for over 3 years. Their conformal coating services and rigorous testing procedures ensure our devices perform reliably even in extreme outdoor environments.

As a startup developing smart home EV chargers, we needed a manufacturing partner who could scale with us. Their flexible production capabilities and global logistics support have been instrumental in our rapid growth and market expansion.

Partner with us for high-quality PCB manufacturing and assembly services tailored to the unique requirements of EV charging devices. Our team is ready to support your project from prototype to production.