Comprehensive and reliable PCB testing services to ensure your printed circuit boards meet the highest quality standards and performance requirements

We provide a comprehensive range of PCB testing services to verify quality and performance, identify defects, and ensure your PCBs meet specification requirements while improving efficiency and reducing costs.

- Experienced PCB inspectors perform visual inspections

- Ensures PCBs are thoroughly examined for surface defects

- Identifies visible issues like scratches, cracks, and imperfections

- Complements automated testing methods

- PCB cross-section analysis for detailed internal examination

- Identifies layer alignment and internal defects

- Checks plating quality and via integrity

- Uses microscopes and scanning electron microscopes

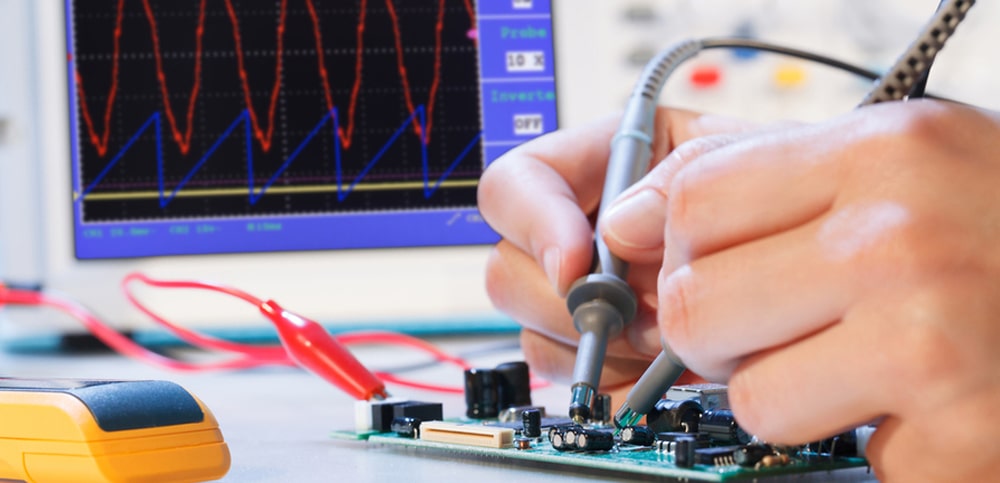

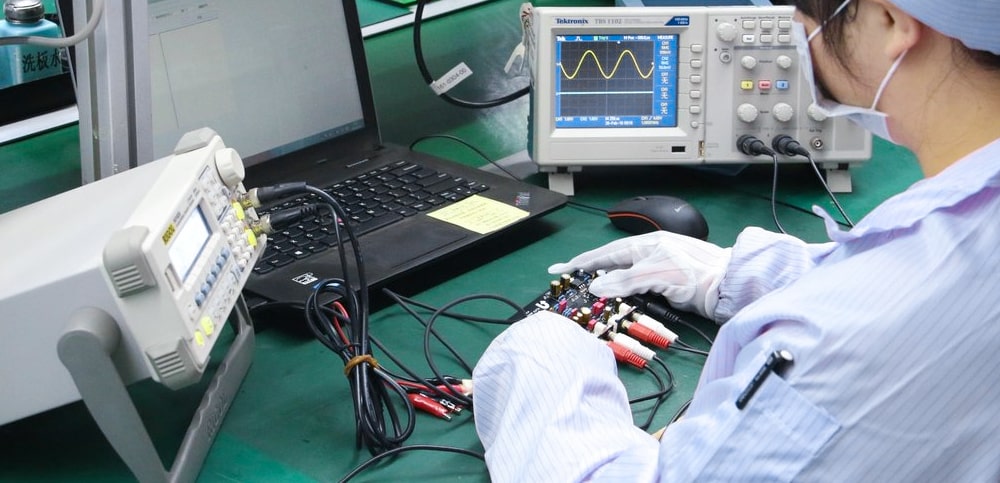

- Verifies electrical parameters and performance

- Includes continuity, isolation, and impedance tests

- Performs high-voltage testing for dielectric strength

- Uses specialized PCB testing equipment and fixtures

- Automated inspection through optical means

- Quickly detects defects in PCB manufacturing process

- Uses high-resolution cameras and image processing

- Identifies shorts, opens, and surface defects on bare PCBs

- Comprehensive testing of unpopulated PCBs

- Verifies continuity and isolation between circuits

- Identifies manufacturing defects in traces and vias

- Uses specialized test equipment and software

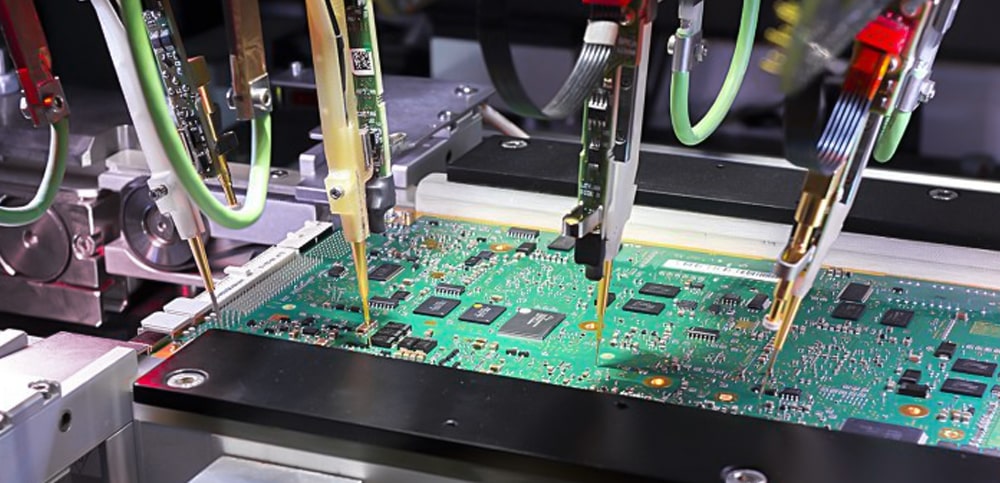

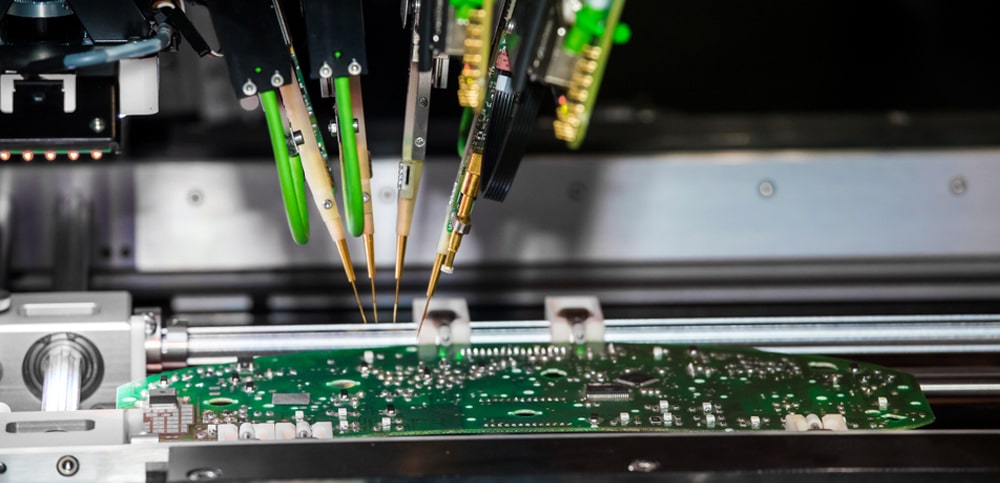

- Uses automated probe system for circuit testing

- No expensive test fixtures required

- Tests any area including small and dense boards

- Ideal for prototype and low-volume PCB testing

- Measures characteristic impedance of PCB traces

- Ensures signal integrity requirements are met

- Critical for high-speed digital and RF applications

- Uses time domain reflectometry (TDR) equipment

We analyze your PCB specifications and testing requirements to develop a customized testing plan

Our experienced inspectors perform detailed manual inspections to identify obvious defects

We utilize advanced equipment like AOI and flying probe for comprehensive PCB testing

We perform thorough electrical tests to verify parameters and performance meet specifications

We conduct impedance testing to ensure PCBs meet signal integrity requirements

Final quality assurance and certification that your PCBs meet all requirements

Contact our team today to discuss your PCB testing requirements and how we can help you achieve the highest quality standards

Oxidation is the hidden limiter in reflow.

— POE PCB/PCBA Manufacturer (@poe_pcba) January 19, 2026

In air, it fights wetting. AOI may pass — consistency won’t.

Nitrogen reflow:

less oxidation → stable wetting → uniform joints.

Why it matters:

fine pitch, tight windows, repeatable builds, fewer latent failures.#NitrogenReflow #SMT pic.twitter.com/OfbjQYjWl7

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China