Complete SMT & THT assembly from prototype to high-volume production. We don't just make boards, we build your product.

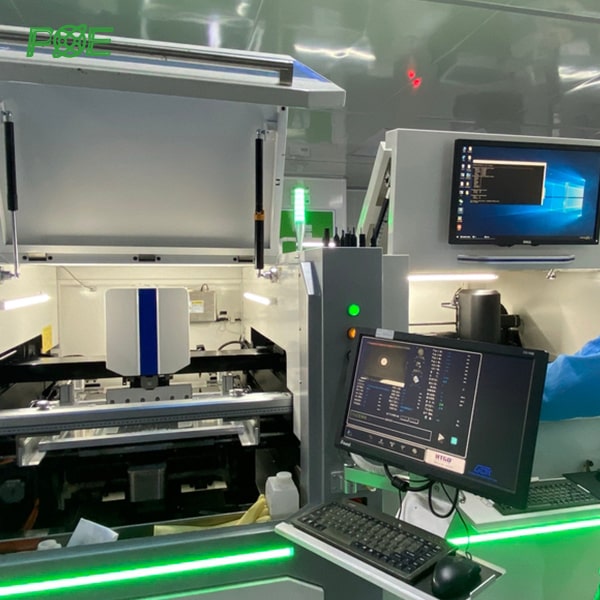

High-speed automated SMT production lines

Micro 01005 to large BGA and QFN packages

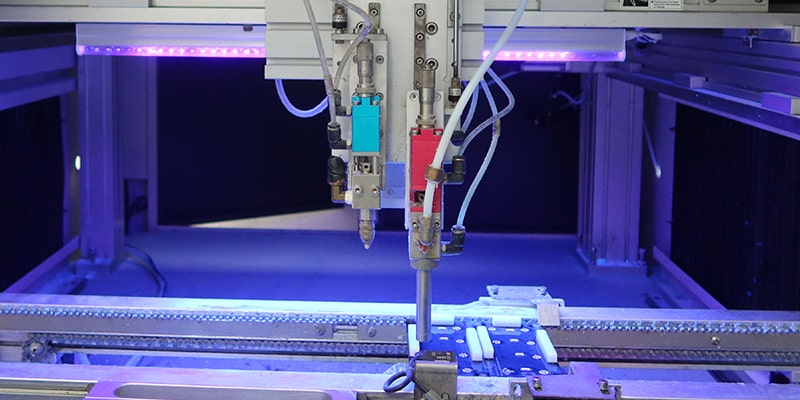

Ultra-high precision for fine-pitch components

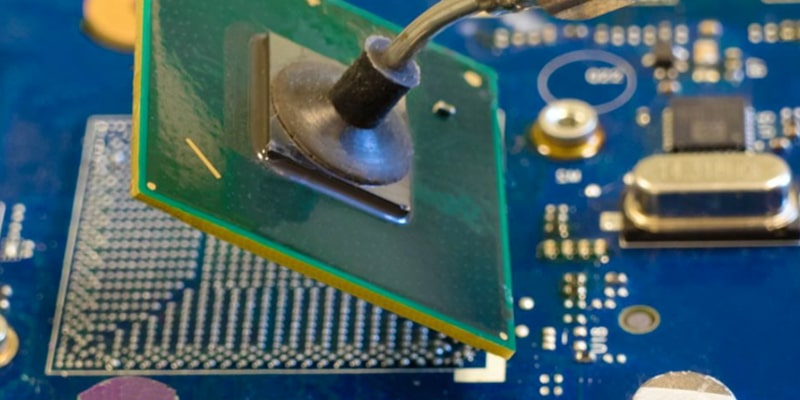

Fine-pitch BGA and micro-BGA assembly

High-volume mass production capability

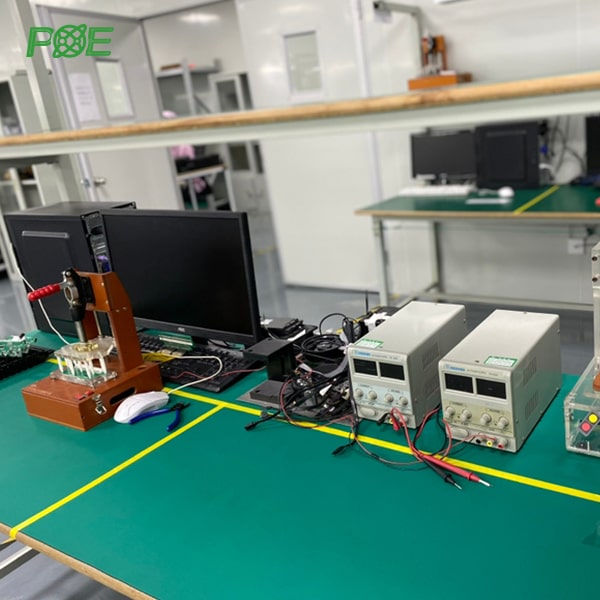

100% AOI, X-ray BGA, functional testing

Full turnkey and consignment assembly

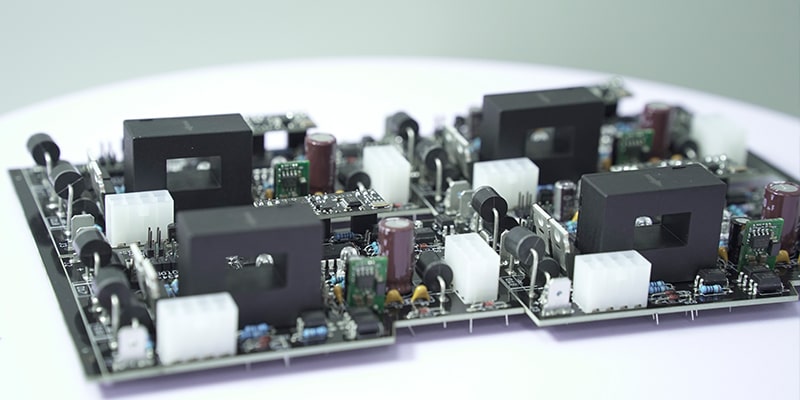

Small IoT to large industrial PCB assembly

Fine-pitch QFP, QFN, and CSP assembly

Nitrogen reflow with precise temperature control

Industry-leading assembly quality rate

Express prototype to volume production

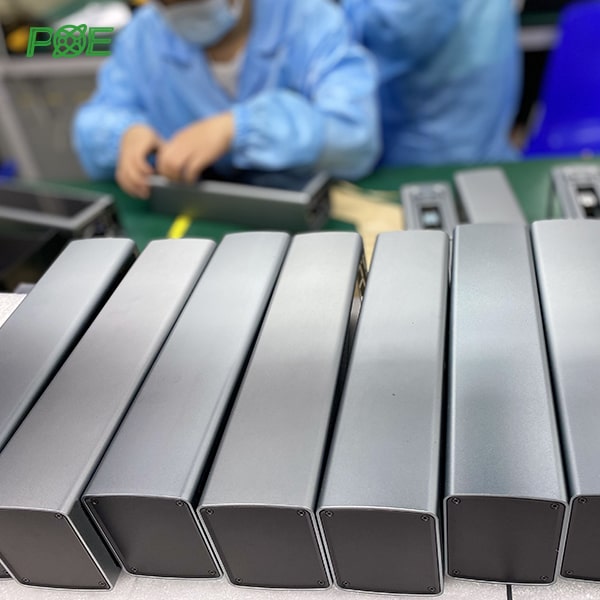

Our advanced PCB assembly facility features 4 high-speed SMT production lines equipped with state-of-the-art pick-and-place machines, reflow ovens, and comprehensive testing equipment. With capabilities ranging from prototype assembly to high-volume production, we handle components from 01005 passives to large BGAs and connectors. Our assembly services include SMT, THT, mixed technology, box build assembly, and complete turnkey solutions with component procurement, testing, and logistics support.

Seamless board feeding system

120K CPH precision assembly

Vision-guided accuracy

Ultra-precise component placement

Real-time quality monitoring

10-zone temperature control

Automated defect detection

Hidden joint analysis

Skilled craftsmanship

Through-hole component insertion

Lead-free mass soldering

Automated case assembly

Custom harness production

Firmware upload & validation

Comprehensive functionality check

Ultrasonic flux removal

Pre-production verification

Moisture control system

High-speed surface mount technology assembly services

Through-hole technology assembly and mixed technology

Complete turnkey solutions with component procurement

Mass production assembly with cost optimization

State-of-the-art SMT lines and precision placement equipment

3-day prototype assembly, 5-10 days production runs

IPC-A-610 certified assembly with comprehensive testing

Complete services from component sourcing to final testing

Exceptional SMT assembly quality with zero defects. Their BGA placement accuracy exceeded our expectations.

Outstanding turnkey assembly service. From component sourcing to final testing, everything was perfect.

Reliable assembly partner for our IoT devices. Fast turnaround and excellent quality control.

Ahead of International Women’s Day (Mar 8)

— POE PCB/PCBA Manufacturer (@poe_pcba) March 6, 2026

To women everywhere—every role, every industry—thank you for the work you do and the standards you raise.

Wishing you recognition today, and health + joy + progress all year. ✨#IWD #InternationalWomensDay #POE pic.twitter.com/5cT2DPBvAR

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China