What's Nitrogen Reflow Soldering?

Reflow soldering is a common process in the electronics manufacturing industry. It melts the solder on electronic components and printed circuit boards by high-temperature heating to connect them to each other. During the soldering process, oxygen will cause oxides to form on the solder surface, affecting the quality of the solder joints and thus the reliability of the product. Nitrogen reflow soldering refers to filling the reflow chamber with nitrogen to reduce the oxidation of the solder surface. Nitrogen is an inert gas that is not easy to react chemically with metals. It isolates the contact between oxygen in the air and electronic components, thereby reducing the volatilization of flux moisture during the reflow process and improving the quality of soldering. Especially for products with high requirements for stability and reliability, a nitrogen furnace is required for soldering.

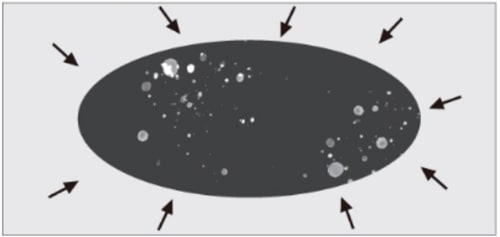

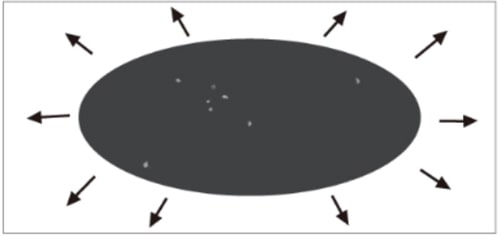

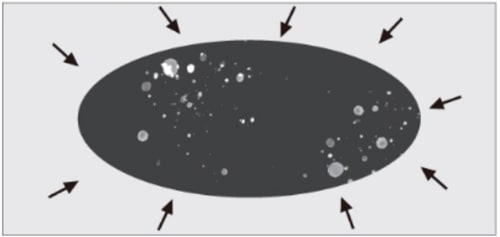

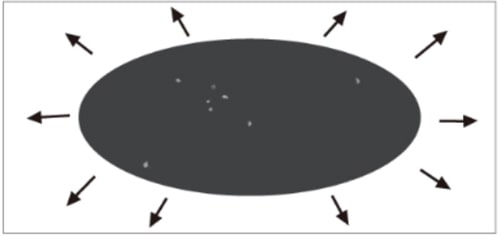

| Standard Reflow Soldering |

Nitrogen Reflow Soldering |

|

|

Secondly, nitrogen can significantly reduce the oxygen concentration in the original air on the material welding surface, thereby greatly reducing the oxidation of solder paste at high temperatures, especially for improving the quality of secondary reflow soldering.

In SMT (surface mount technology) patches, when the first side of the PCB is reflowed, the surface treatment of the second side of the circuit board is also exposed to a high temperature environment and is easily damaged by high temperature. Especially for circuit boards with OSP (Organic Solderability Preservative) surface treatment, the oxidation rate is fast at high temperature, which is easy to cause damage. By introducing nitrogen, the oxidation degree of the second side surface treatment during the first side reflow process can be significantly reduced, so that the second side can better withstand the reflow process and ensure the best welding effect.

By introducing nitrogen, the degree of oxidation of the second-side surface treatment can be significantly reduced during the first-side reflow soldering process. Consequently, the second side can better withstand the reflow oven process, ensuring the bestsolderigffect.

Nitrogen SMT reflow ovens with 10 temperature zones

Avoid solder balls, bridging and assure best solder joint .

Prevent oxidation during reflow heating.

Assure stable soldering and speed up the soldering speed.

99.99% nitrogen in the reflow oven shines the solder pads and reach the best performance.

Nitrogen Reflow Soldering Advantages

1.Improvement of Soldering Quality: Nitrogen reflow soldering effectively reduces the generation of oxides, improves the wetting of solder joints, makes the surface of solder joints smoother and reduces defects. Nitrogen (N2) injection reduces oxygen levels (<100 ppm), improving solder wettability and producing smoother, shinier joints with fewer voids.

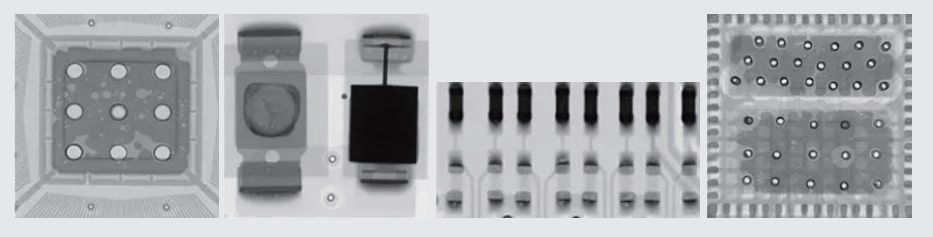

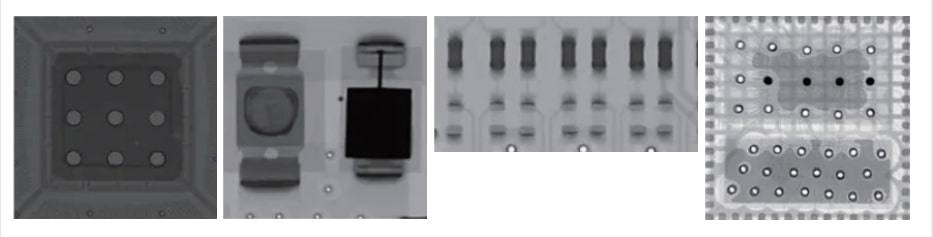

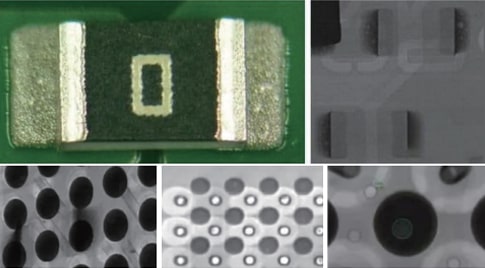

| Standard Reflow Soldering: Oxygen in ambient air causes solder oxidation, leading to dross formation and cold joints (especially with lead-free solder). |

Nitrogen Reflow Soldering: Nitrogen (N2) injection reduces oxygen levels (<100 ppm), improving solder wettability and producing smoother, shinier joints with fewer voids. |

|

|

|

Standard Reflow Soldering |

|

Nitrogen Reflow Soldering |

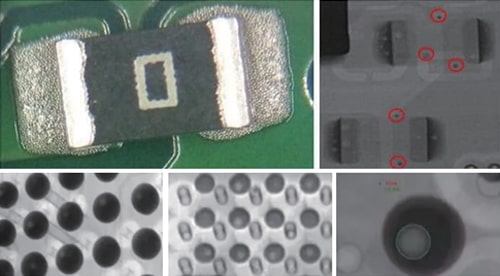

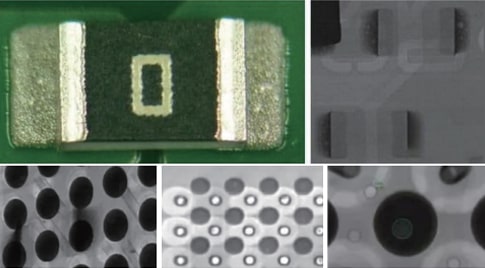

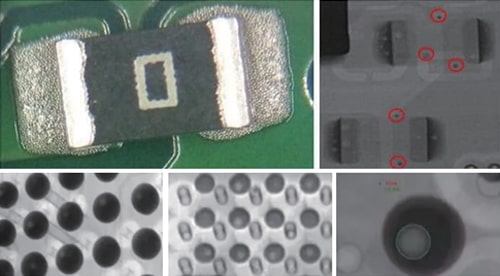

2.Increased Reliability and Strong adaptability: Nitrogen reflow soldering reduces the oxygen content of the soldered area, helping to minimize the brittleness of the soldered interface and improving the long-term reliability of electronic assemblies. And it is applicable to a variety of welding processes and materials to meet different production requirements.

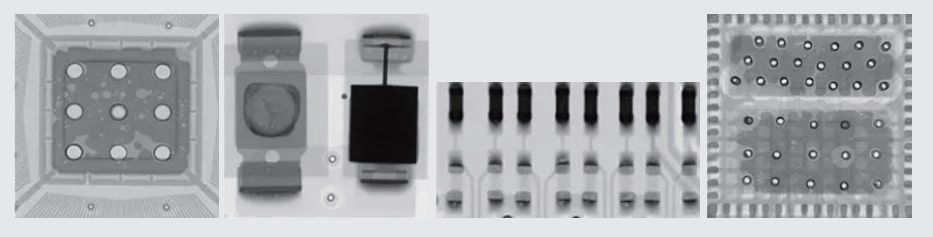

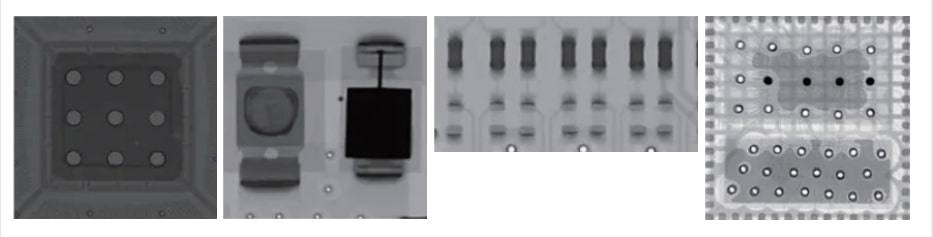

|

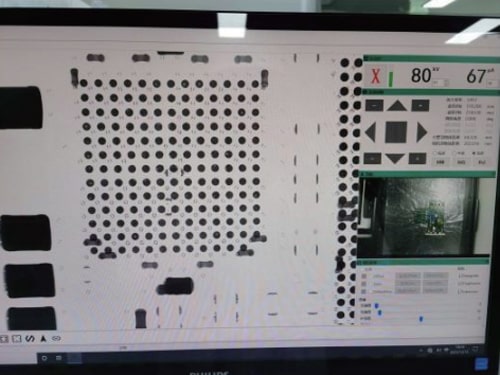

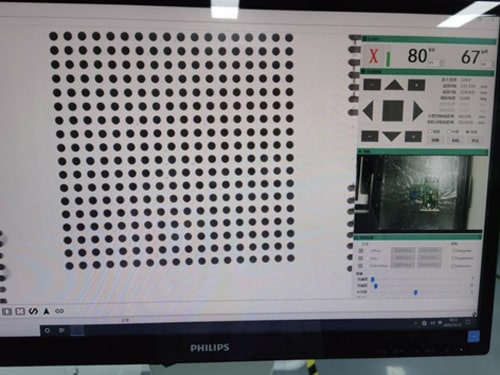

Regular Air Oven Soldering under X-Ray

Good Quality

Good Stability

Recommend for high demand products

|

Nitrogen Oven Soldering under X-Ray

High Quality

High Stability

Recommend for high-end products

|

|

|

|

|

|

3.Reduced Soldering Defects: Nitrogen reflow soldering significantly reduces common soldering defects such as short circuits, voided welds, solder balls, and cracks, increasing production yields. It can also reduced flux residue, Nitrogen suppresses high-temperature carbonization of flux, minimizing residue on PCBs, eliminates post-solder cleaning steps, ideal for no-clean processes.

4.Extended Equipment Life: Nitrogen reduces oxidation and corrosion in the furnace, reduces equipment maintenance frequency, and extends service life.

5.Environmental Protection and Energy Saving: Nitrogen furnace reduces the emission of harmful gases and meets the requirements of environmental protection, optimizes the heat conduction and reduces the energy consumption and at the same time.

Nitrogen Reflow Soldering Applicable Products/Areas

1.Nitrogen reflow soldering reduces the defective rate if the welding precision is in high requirements.

2 OSP surface treatment of double-sided reflow soldering board is suitable for the use of nitrogen furnace.

3 Large packages and high-density BGAs, as well as boards with small components below 0201.

4.Suitable for high-precision, ultra-high requirements of semiconductor, aerospace, defense industry, medical, automotive electronics, 5G communications, LED and other fields.