IQC (Incoming Quality Control) inspection refers to the inspection of raw materials, parts, etc. before entering the production process to ensure that they meet quality requirements and specifications. In IQC components inspection, POE strictly controls and checks the quality of components. Common inspection methods include component reception and identification, visual inspection, dimensional inspection, physical property inspection, chemical composition analysis, non-destructive inspection, etc.

Sample reception and identification

Before the start of IQC inspection, raw materials, parts, etc. need to be received and identified. When receiving, it is necessary to check whether the name, quantity, batch number, manufacturer, production date and other information of the components are correct, and mark them for subsequent inspection and traceability.

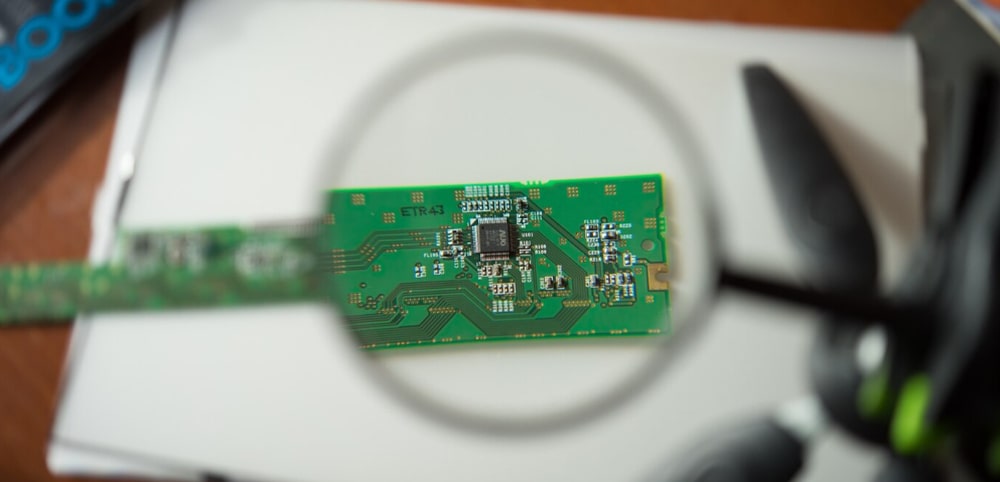

Visual inspection

Visual inspection is the simplest inspection method. The appearance of the components is observed by the naked eye to determine whether it meets the requirements. This inspection method does not require additional equipment and tools, and is simple to operate, but it cannot detect internal quality problems, and can only detect external defects, such as surface flaws.

Dimension inspection

Dimension inspection is a relatively common inspection method, which uses whether the size and geometry of the components meet the requirements as the judgment standard. This inspection method requires the use of measuring tools, such as calipers and gauges, to detect whether the componentssize meets the standard requirements.

Physical performance inspection

Physical performance inspection is to determine whether the components meets the technical specifications by testing the physical properties of the components, such as hardness, strength, etc. This inspection method requires the use of specific testing equipment and instruments to detect the basic physical performance indicators of the components.

Chemical composition analysis

Chemical composition analysis is to analyze the composition of the components by chemical means to determine whether it meets the requirements. This inspection method requires the use of specific chemical analysis instruments and equipment to detect whether the chemical composition of the material meets the technical specifications and can detect some internal quality problems.

Non-destructive inspection

Non-destructive inspection is to determine whether the compo nents meets the technical specifications by non-destructive testing of the components. This inspection method will not damage or destroy the components, and usually uses methods such as acoustic wave detection and X-ray detection. This inspection method can detect internal quality problems of the components.

Other tests

In addition to the above test methods, other test methods can be selected according to the characteristics and uses of the components, such as electrical performance test, thermal performance test, etc. These test methods can help detect more quality problems and defects.

POE strictly abides by the IQC inspection process, reasonably selects inspection methods to determine quality, and needs to record and handle the problems found. Only by passing the IQC inspection and ensuring that the quality of raw materials and parts entering the production line meets the standards and product requirements can the finished products meet thel quality requirements.

Component storage

1.The harm of improper storage

PCBA factories have high requirements for the storage environment of electronic components and products in stock, especially for humidity requirements. Excessive humidity will cause great harm to electronic products and SMT processing components, plug-in components, etc. It is reported that more than 1/4 of industrial manufacturing defective products in the world are related to the harm of moisture every year. Moisture is already a major problem affecting product quality, so why is the harm of moisture so great? Here is a brief introduction to the harm of humidity to various products and devices.

Integrated circuit: Moisture can penetrate the plastic package of IC and penetrate into the IC from gaps such as pins, resulting in IC moisture absorption. Then, water vapor is formed during the welding and heating process of SMT processing, which eventually causes the resin package of IC to crack and internal oxidation, resulting in product failure.

Liquid crystal devices: Although the glass substrates, polarizers, and filters of liquid crystal devices such as liquid crystal displays need to be cleaned and dried during the production process, they will still be affected by moisture after cooling, which will lead to a decrease in the product qualification rate.

Other electronic devices: capacitors, ceramic devices, connectors, switches, solder, PcB, crystals, silicon wafers, quartz oscillators, SMT glue, electrode material adhesives, electronic pastes, high-brightness devices and other components are all under the harm of moisture.

Electronic devices in the operation process: between semi-finished products in packaging and the next process; before PCBA packaging and between packaging and power-on; ICs, BGAs, PCBs, etc. that have been unpacked but not yet used; devices waiting for soldering in the tin furnace; devices that have been baked and are waiting to be warmed up; finished products that have not yet been packaged, etc., will all be harmed by moisture.

Finished electronic devices will also be harmed by moisture during storage in the PCBA factory. The humidity of the PCBA factory production and product storage environment should be below 40%. Some components also require lower humidity.

2.PCBA component storage management

Temperature and humidity control

Most electronic components should be stored in an environment between 0°C and 30℃ (32°F to 86°F). For sensitive components, such as integrated circuits (ICs), stricter control may be required, such as a temperature between 5° C and 25° C (41° F to 77° F). Too high or too low temperatures can cause damage to components, such as changes in resistance values, drift in capacitance values, and hardening or softening of soldering materials. The ideal relative humidity should be maintained between 30% and 60% to avoid metal corrosion caused by excessive humidity, solder joint oxidation, or static electricity accumulation caused by low humidity.

Anti-static measures

Electrostatic discharge (ESD) is a common threat in the storage of electronic components. ESD can destroy sensitive componen in an instant, so all storage areas should be equipped with anti-static floors or mats, workbenches, and anti-static packagin materials such as conductive bags and foam pads to store electrostatic sensitive components. POE workers wear anti-stat wristbands and anti-static clothing to reduce the risk of electrostatic discharge.Electrostatic discharge (ESD) is a common threat in the storage of electronic components. ESD can destroy sensitive components in an instant, so all storage areas should be equipped with anti-static floors or mats, workbenches, and anti-static packaging materials such as conductive bags and foam pads to store electrostatic sensitive components. POE workers wear anti-static wristbands and anti-static clothing to reduce the risk of electrostatic discharge.

Packaging and labeling

Electronic components should be packaged in moisture-proof and anti-static packag ing materials, such as aluminum foil bags and anti-static plastic bags, to isolate them from the outside environment. Each batch of components should be clearly labeled with the product name, model, production date, shelf life and special storage require ments for easy tracking and management.

Cleaning and handling

Avoid touching sensitive electronic components directly with your hands and use anti-static gloves or finger covers. The storage area should be kept clean and free of dust and other contaminants.

Storage period

Some components, especially those with moisture sensitive indicators (MSL) packages, have a specific storage period. After the period, re-baking or inspection may be required. POE followed the recommended storage time and conditions in the manufac turer's data sheet. The storage area should be cleaned and inspected regularly to ensure that the environmental conditions meet the standards. At the same time, the status of components should be checked and aging or damaged packaging materials should be replaced in time.

First-in-first-out (FIFO) principle

In order to ensure the freshness and functionality of components, POE adopt first-in-first-out principle to manage inventory. That is, the components that enter the warehouse first are the first to leave the warehouse, which can minimize the risk of expiration and loss and ensure that the freshest components are used.