What is Conformal Coating?

What is Conformal Coating?

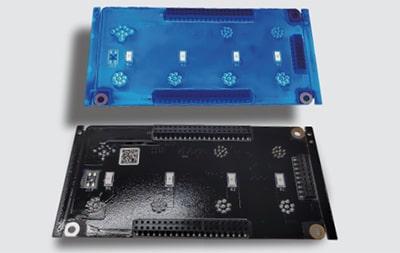

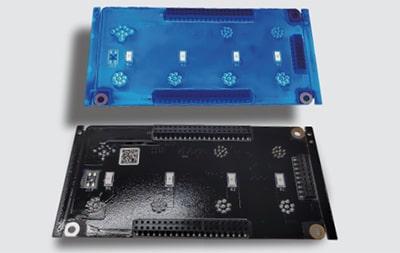

Conformal coating is a thin, protective film applied to PCBAs to protect the delicate electronic components from external factors such as moisture, dust, chemicals, and temperature variations. Unlike traditional encapsulation methods, conformal coatings are designed to conform to the contours of the PCB, providing a precise and efficient protective layer without adding significant weight or bulk.

Benefits of Conformal Coating

|

|

| Conformal Coating |

NO Conformal Coating |

Environmental Protection: Conformal coatings safeguard against moisture, dust, and chemical contaminants, which can cause corrosion, short circuits, and other forms of damage.

Enhanced Durability: The coating helps to withstand mechanical stress and vibrations, making PCBAs more robust in harsh environments.

Electrical Insulation: By providing a non-conductive layer, conformal coatings prevent electrical shorts and enhance the performance of high-voltage circuits.

Thermal Management: Certain types of coatings can improve heat dissipation, aiding in the thermal management of electronic components.

Extended Lifespan: Overall, the protection offered by conformal coatings significantly extends the operational life of electronic devices, leading to better reliability and reducing maintenance costs.

Conformal Coating Process & Methods

Application Methods

Manual Spraying

Automated Spraying

Selective Coating

Dipping

Brushing

Vapor Deposition

Key Features and Benefits for Coating Machine

High Accuracy and Repeatability

Windows-based Software Control with User-friendly Interface

Ease of Programming

Profile Sharing Between Multiple Coating Systems; Including Previous Precision Coat Models

SCS Designed Valves

Multiple Dispensing and Mixing Solutions

Interior LED Lighting

SMEMA Transfer Protocols

CFX Compatible

Safety Interlocks

Internal Black Light for Coating Inspection

External Reservoirs for Fluid Feeding

HDY-H302 Selective Coating Machine

HDY-H302 Selective Coating Machine

| Frame Size |

1050mm(L) * 1375mm(W) * 1490mm(H) |

| Operation Mode |

Industrial Computer + Motion Control Card |

| PCB Transmission Height |

920 + 20mm |

| Transport Speed |

0-5000mm/min |

| Transmission Direction |

L→R(R→L) |

| PCB Board Size |

MAX 45mm(W) *450mm(L) |

| XY Motion Drive Mode |

Panasonic Servo Motor+Precision Module Drive |

| XY Movement Speed |

600mm/s |

| PCB Board Component Height |

MAX +100mm |

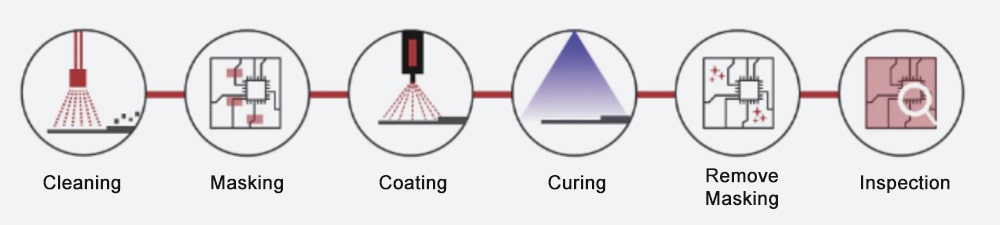

How to Ensure the Quality in the Conformal Coating Process 1.Choose the Right Material

1.Choose the Right Material

There are different types of conformal coating materials, such as acrylic, silicone, epoxy, urethane, and parylene. Each one has its own advantages and disadvantages, depending on your application and requirements. You should consider factors such as adhesion, flexibility, resistance, curing time, and cost when selecting the best material for your project. You should also consult the datasheets and specifications of the coating and the components to avoid compatibility issues.2.Prepare the Surface

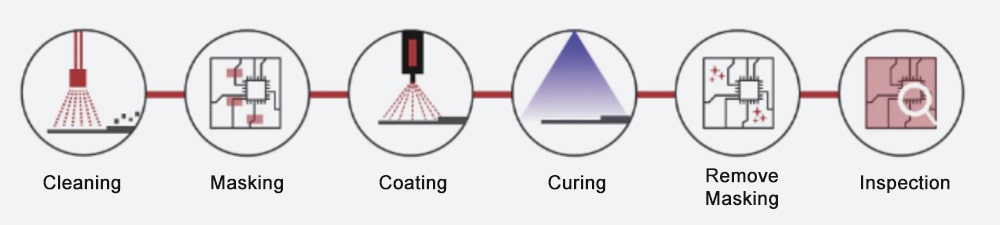

Before applying the conformal coating, you need to make sure that the surface of the circuit board is clean and free of contaminants, such as dust, grease, flux residues, or solder balls. You can use different methods to clean the surface, such as brushing, wiping, spraying, or ultrasonic cleaning. You should also inspect the surface for any defects, such as cracks, scratches, or delamination. You can use a magnifying glass or a microscope to check for any imperfections.3.Mask the Areas

Some areas of the circuit board, such as connectors, switches, potentiometers, or test points, should not be coated, as they need to remain functional or accessible. You can use masking materials, such as tapes, dots, boots, or plugs, to cover these areas and prevent the coating from reaching them. You should apply the masking materials carefully and securely, and remove them after the coating is cured. You should also avoid using masking materials that can leave residues or damage the surface.4.Apply the Coating

There are different methods to apply the conformal coating, such as brushing, dipping, spraying, or vapor deposition. Each method has its own benefits and drawbacks, depending on the coating material, the board size and shape, the production volume, and the desired thickness and uniformity. You should follow the manufacturer's instructions and recommendations for the optimal application parameters, such as temperature, pressure, speed, and distance. You should also use appropriate equipment and tools, such as nozzles, valves, dispensers, or robots, to ensure accuracy and consistency. 5.Cure the Coating

After applying the conformal coating, you need to cure it properly to ensure its durability and performance. The curing process depends on the type of coating material and the method of application. Some coatings can cure at room temperature, while others need heat, moisture, or ultraviolet light to cure. You should follow the manufacturer's guidelines and specifications for the optimal curing time and conditions. You should also monitor the curing process and avoid touching or moving the boards until they are fully cured.6.Inspect the Coating

The final step of the conformal coating process is to inspect the quality and integrity of the coating. You can use different techniques to inspect the coating, such as visual inspection, optical inspection, fluorescence inspection, or electrical testing. You should look for any defects, such as bubbles, cracks, pinholes, or delamination, that can compromise the protection and functionality of the coating. You should also measure the thickness and uniformity of the coating, and compare them with the expected standards and tolerances.Silicone and Its Application ScenariosSilicone rubber is widely used in electronics due to its many favourable qualities. ( Silicone Coating Properties: High Chemical Stability, including Ultraviolet (UV) and Ozone Degradation/Good Moisture Resistance/ High Dielectric Strength/Low Surface Energy / Flexibility / Ease of Rework /Light Transmission Capabilities /Excellent Performance in Extreme Temperatures). Applications:Home AppliancePCBA Television, Washing Machine, Range Hood, Water Heater, Air Conditioner, Refrigerator, Soybean Milk Machines, Electric Toothbrushes, etd.LED PCBADisplay Screens, Car Lighting, Road Lighting, Operating Room Lighting, Explosion-proof Lights, Mining Lights, Wall Washers, Signal Lights, Tunnel lights, etc.Power Bank PCBAPower Supply, Sensors, High-voltage Switches, Servers, Solenoid Valves, Radiators, Linear Motors, etcCommunication PCBAMobile Phones, Wired Phones, 5GIOT, Intercoms, Switches, Routers, Radios, Converters, Wireless Network Cards, Transmitters, Radios, etc.Instrumentation PCBAElectronic Scales, Smart Water Meters, Smart Gas Meters,Smart Electric meters, Optical Instruments, Thermometers, etc.Industrial PCBAElectric Drills, Chainsaws, Impact Drills, Polishing Machines, Cutting Machines, Laser Machines, Electric Wrenches, Welding Machines, etc.Vehicle PCBAElectric Vehicles, Motorcycles, Handling Robots, Shared Bikes, High-speed Trains, Subways, Ships, Yachts, Electric Cars, etc.Security PCBASurveillance Cameras, Smart Locks, Access Control Devices, Parking Lot Machines, Attendance Machines, Alarms, Electronic Cat Eyes, etc.New Energy PCBALithium Batteries, Wind Power Equipment, Geothermal Equipment, Solar Panels, Power Batteries, Charging Stations, Power Transmitters, etc.Aerospace PCBAGliders, Airships, Airplanes, Helicopters, Drones, Satellites, Space Probes, Space Shuttles, etc.Smart Electronics PCBASmartphones, Tablets, Smart Bracelets, Smart Watches, Smart Speakers, Floor Cleaning Robots, Digital Cameras, Beauty Devices, Fans, Refrigerators, etc.Robot PCBAIndustrial Robots (Production, Handling, Assembly Testing), Medical Robots, Catering Service Robots, Agricultural Robots, Educational Robots, Sweeping Robots, Military Robots, etc.

Applications:Home AppliancePCBA Television, Washing Machine, Range Hood, Water Heater, Air Conditioner, Refrigerator, Soybean Milk Machines, Electric Toothbrushes, etd.LED PCBADisplay Screens, Car Lighting, Road Lighting, Operating Room Lighting, Explosion-proof Lights, Mining Lights, Wall Washers, Signal Lights, Tunnel lights, etc.Power Bank PCBAPower Supply, Sensors, High-voltage Switches, Servers, Solenoid Valves, Radiators, Linear Motors, etcCommunication PCBAMobile Phones, Wired Phones, 5GIOT, Intercoms, Switches, Routers, Radios, Converters, Wireless Network Cards, Transmitters, Radios, etc.Instrumentation PCBAElectronic Scales, Smart Water Meters, Smart Gas Meters,Smart Electric meters, Optical Instruments, Thermometers, etc.Industrial PCBAElectric Drills, Chainsaws, Impact Drills, Polishing Machines, Cutting Machines, Laser Machines, Electric Wrenches, Welding Machines, etc.Vehicle PCBAElectric Vehicles, Motorcycles, Handling Robots, Shared Bikes, High-speed Trains, Subways, Ships, Yachts, Electric Cars, etc.Security PCBASurveillance Cameras, Smart Locks, Access Control Devices, Parking Lot Machines, Attendance Machines, Alarms, Electronic Cat Eyes, etc.New Energy PCBALithium Batteries, Wind Power Equipment, Geothermal Equipment, Solar Panels, Power Batteries, Charging Stations, Power Transmitters, etc.Aerospace PCBAGliders, Airships, Airplanes, Helicopters, Drones, Satellites, Space Probes, Space Shuttles, etc.Smart Electronics PCBASmartphones, Tablets, Smart Bracelets, Smart Watches, Smart Speakers, Floor Cleaning Robots, Digital Cameras, Beauty Devices, Fans, Refrigerators, etc.Robot PCBAIndustrial Robots (Production, Handling, Assembly Testing), Medical Robots, Catering Service Robots, Agricultural Robots, Educational Robots, Sweeping Robots, Military Robots, etc.

Share This Story, Choose Your Platform!