The Role of Copper Foil in PCB

12 December 2025

Views: 614

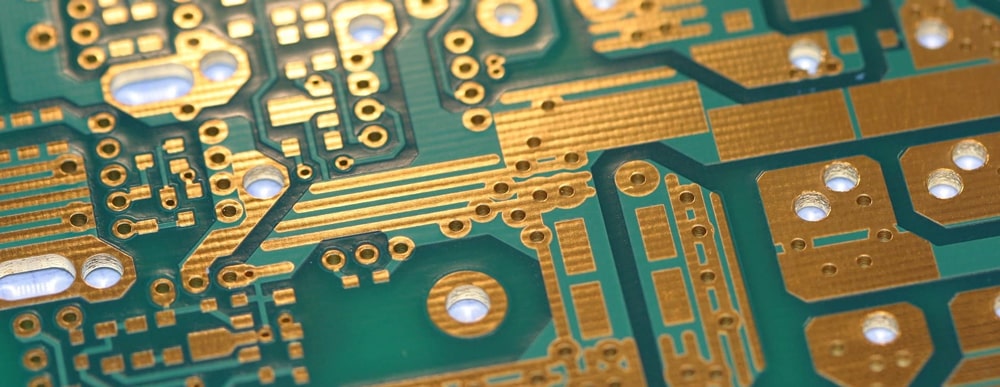

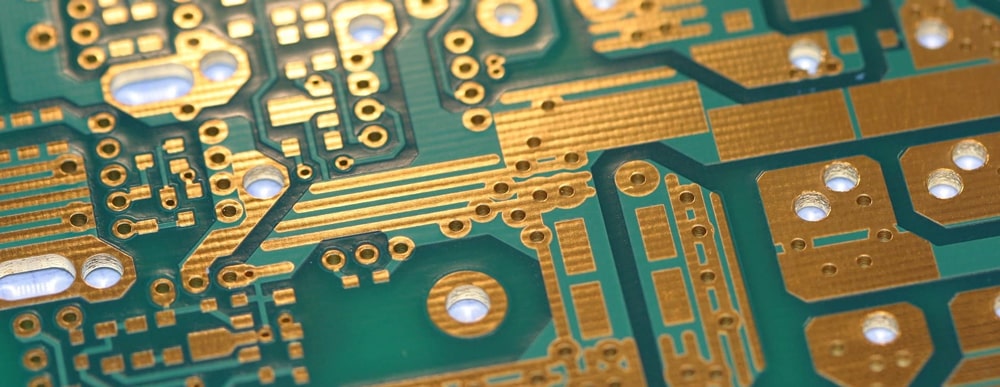

Copper foil is a basic material in PCB manufacturing and is the conductive path for signals. It acts as the main conductive layer, enabling electrical signals and power to be transmitted throughout the circuit.

What is copper foil in PCBs?

Copper foil is a thin copper sheet laminated on a substrate material (such as FR-4) to form the conductive layer of a PCB. It can create conductive tracks, pads, and vias to connect different components and layers.

The thickness of copper foil is measured in ounces per square foot (oz/ft²). The choice of thickness depends on the current carrying capacity and design requirements of the PCB. Common thicknesses include:

1 oz/ft² (35 microns);

2 oz/ft² (70 microns);

3 oz/ft² (105 microns).

The Role of Copper Foil in PCBs

1. Conductivity

Copper foil provides an electrical pathway that connects the various components on the PCB. The pathway is used for signal and power transmission between components.

2. Thermal conductivity

Copper has excellent thermal conductivity and helps dissipate the heat generated by electronic components.

3. Structural support

It can enhance the strength of the circuit board and maintain its structural integrity during welding and operation.

Conclusion

Copper foil is the basic material in PCB manufacturing. It is the conduction path of the signal and has the functions of electrical conduction, thermal conduction and structural support.

Share This Story, Choose Your Platform!

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China