Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the pro duction of smaller, faster, and more reliable electronic devices. As the demand for high-quality electronic prod ucts continues to grow, the importance of maintaining and optimizing SMT equipment cannot be overstated. This article delves into the critical aspects of SMT equipment maintenance and performance optimization, providing insights and best practices to ensure optimal operation and longevity of SMT machinery.

1. Understanding SMT Equipment

SMT equipment encompasses a range of machines used in the assembly of electronic components onto printed circuit boards (PCBs). Key components of SMT equipment include:

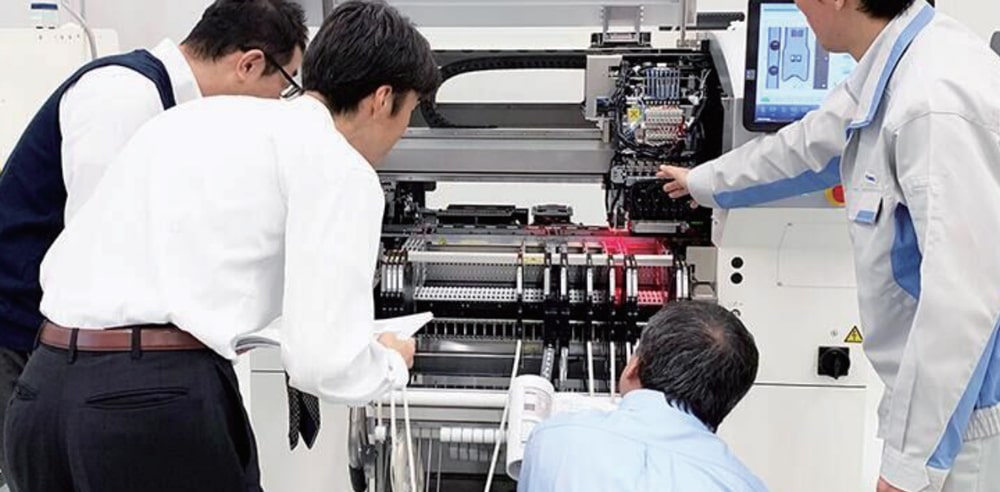

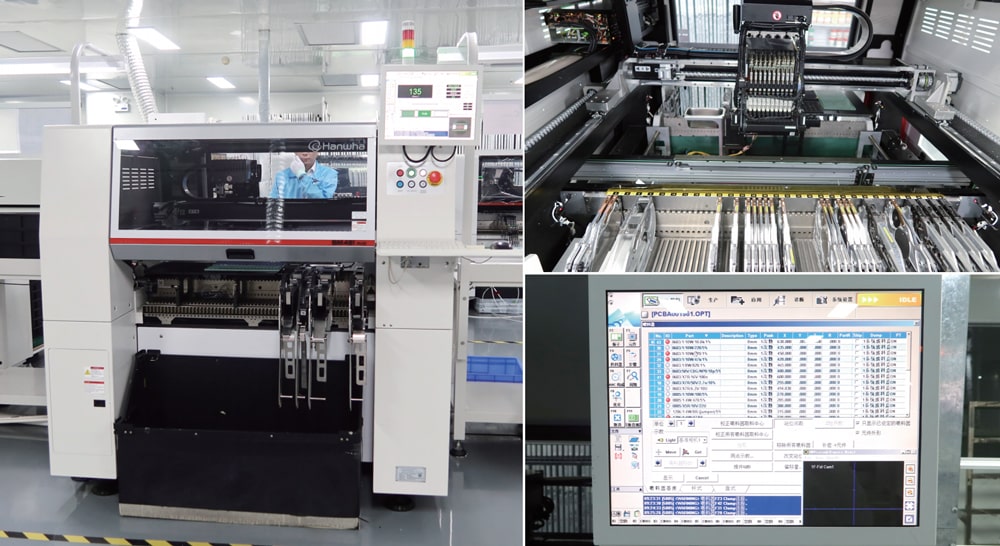

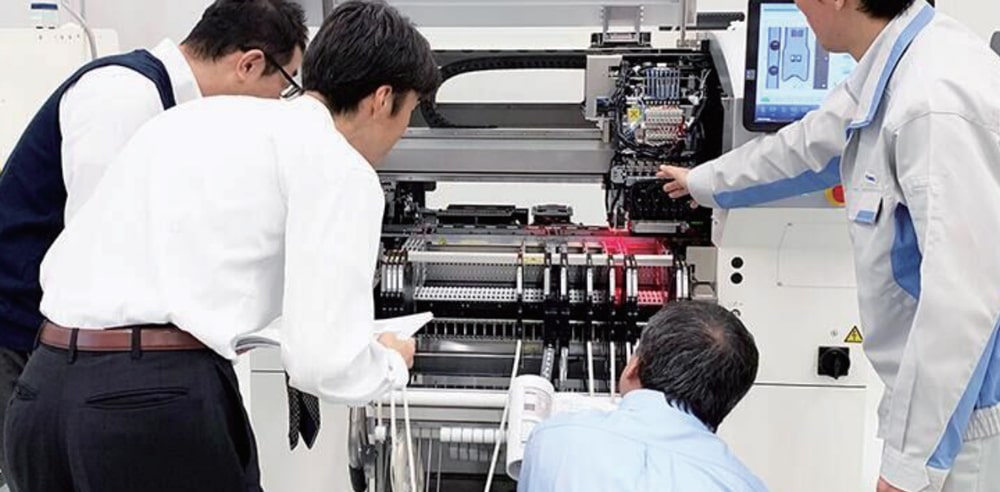

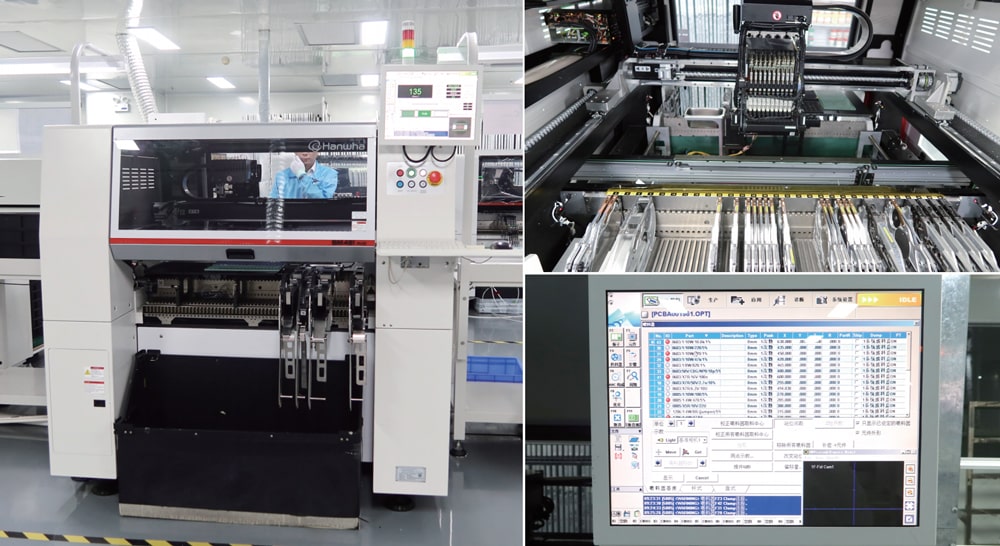

Pick-and-Place Machines: These machines accurately place surface-mount components onto PCBs.

Reflow Ovens: Used to solder components onto the PCB by heating the board to a specific temperature.

Stencil Printers: Apply solder paste to the PCB before component placement.

Inspection Systems: Include 3D SPI, Automated Optical Inspection (AOI) and X-ray inspection systems to ensure quality and detect defects.

2. Importance of Regular Maintenance

Regular maintenance of SMT equipment is crucial for several reasons:

Minimizing Downtime: Preventive maintenance reduces the likelihood of unexpected breakdowns, ensuring continuous production.

Extending Equipment Lifespan: Proper care and maintenance can significantly extend the operational life of SMT machines.

Ensuring Quality: Well-maintained equipment operates more consistently, leading to higher-quality products.

Cost Savings: Preventive maintenance is generally less costly than emergency repairs and can help avoid expensive production delays.

3. Key Maintenance Practices

Effective maintenance of SMT equipment involves a combination of routine checks, cleaning, and timely repairs. Below are some essential maintenance practices:

3.1. Daily Maintenance

Cleaning: Regularly clean the machines to remove dust, solder paste, and other contaminants. Pay special attention to nozzles, conveyors, and cameras.

Inspection: Perform visual inspections to identify any signs of wear, misalignment, or damage.

Lubrication: Ensure that moving parts are adequately lubricated to reduce friction and wear.

3.2. Weekly Maintenance

Calibration: Check and calibrate machines to ensure accuracy in component placement and soldering.

Filter Replacement: Replace air filters and other consumables as needed to maintain optimal performance.

Software Updates: Ensure that the machine's software is up-to-date to benefit from the latest features and bug fixes.

3.3.Monthly Maintenance

Comprehensive Inspection: Conduct a thorough inspection of all machine components, including belts, motors, and sensors.

Alignment Check: Verify the alignment of pick-and-place heads, stencil printers, and conveyors.

Performance Testing: Run performance tests to identify any deviations from expected operation.

3.4.Annual Maintenance

Professional Servicing: Schedule annual servicing by certified technicians to perform indepth diagnostics and repairs.

Component Replacement: Replace worn-out or outdated components to maintain efficiency and reliability.

System Overhaul: Consider a complete system overhaul if the equipment has been in use for several years.

4. Performance Optimization Techniques

Beyond regular maintenance, optimizing the performance of SMT equipment involves implementing advanced techniques and best practices to enhance efficiency and output quality.

4.1. Process Optimization

Line Balancing: Ensure that the production line is balanced to avoid bottlenecks and maximize throughput.

Optimized Solder Paste Application: Fine-tune stencil printing parameters to achieve consistent solder paste deposition.

Reflow Profile Optimization: Develop and maintain optimal reflow profiles to ensure proper soldering and minimize defects.

4.2. Advanced Monitoring and Control

Real-Time Monitoring: Implement real-time monitoring systems to track machine performance and detect anomalies promptly.

Predictive Maintenance: Use predictive maintenance tools and algorithms to anticipate and address potential issues before they lead to downtime.

Data Analytics: Leverage data analytics to gain insights into production trends and identify areas for improvement.

4.3. Training and Skill Development

Operator Training: Provide comprehensive training for machine operators to ensure they are proficient in operating and maintaining SMT equipment.

Continuous Learning: Encourage continuous learning and skill development to keep up with the latest advancements in SMT technology.

4.4. Equipment Upgrades

Technology Upgrades: Invest in the latest SMT equipment and technologies to stay competitive and improve production capabilities.

Retrofitting: Consider retrofitting older machines with new features and components to enhance their performance and extend their lifespan.

5. Common Challenges and Solutions

Despite best efforts, SMT equipment maintenance and performance optimization can present several challenges. Here are some common issues and their solutions:

5.1. Component Misplacement

Cause: Misalignment or calibration issues in pick-and-place machines.

Solution: Regularly calibrate and align the machines, and ensure that components are correctly fed into the system.

5.2. Solder Defects

Cause: Improper solder paste application or reflow profile.

Solution: Optimize stencil printing parameters and reflow profiles, and conduct regular inspections to detect and rectify defects early.

5.3. Machine Downtime

Cause: Lack of preventive maintenance or unexpected breakdowns.

Solution: Implement a robust preventive maintenance schedule and use predictive maintenance tools to minimize downtime.

5.4. Inconsistent Performance

Cause: Wear and tear of machine components or outdated software.

Solution: Regularly replace worn-out components and keep the machine's software up-to-date.

Maintaining and optimizing SMT equipment is essential for ensuring high-quality production, minimizing downtime, and extending the lifespan of the machinery. By implementing regular maintenance practices, leveraging advanced optimization techniques, and staying abreast of emerging trends, manufacturers can achieve superior performance and remain competitive in the ever-evolving electronics industry. As technology continues to advance, the importance of proactive and innovative approaches to SMT equipment maintenance and optimization will only grow, paving the way for more efficient and reliable manufacturing processes.