| Off-line Programming | On-line Programming (ISP) | |

| Versatility | Suitable for all types of chips | Applicable only in two cases 1) Chip supports ISP 2) Circuit board is designed for ISP with proper pin access. |

| Productivity | (1) Programming Speed Programming speed is usually higher in case of offline programming as we have easy access to parallel interface of chips and speed is faster with parallel data transmission. (2) Concurrent Programming SuperBOT-3 is equipped with 32 sockets so concurrent programming of 32 chips is easily possible in most cases. (3) Throughput Automatic programmers can operate at throughput of 1600 UPH (Units per hour) (4) Other Expenses Programming is an independent process, and will not have any effect on testing cost. |

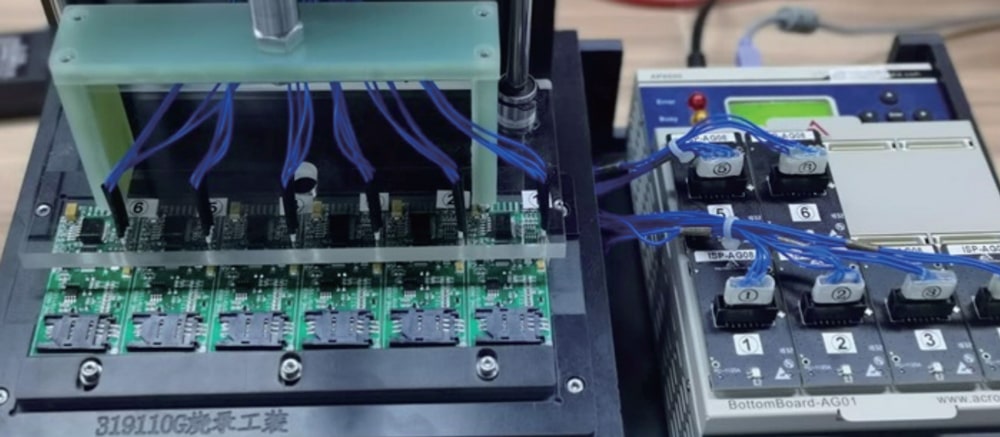

(1) Programming Speed. Programming speed is slower in case of serial programming as compared to parallel programming done by automated/parallel programmers as the data bits are transferred sequentially. (2)Concurrent Programming Concurrent programming is decided by the number of channels each ISP programmer supports and size of PCB panel is also a limiting factor. With smaller size PCB, larger panel can be supported. Superpro IS03 can support a panel of 16 PCBs. (3)Throughput: It is not as high as automated programmers. (4)Other Expenses: If programming is done on an ICT then extra time is needed on the tester which may involve additional operating cost. |

| Investment | Initial Investment is higher and user has to consider operating costs for the socket adapters. The cost is easily recovered if chip programming requirement is very high. |

Initial investment is lower and customer should consider cost for pogo pin replacement along with cost of manual operator. |

| Rework difficulty | For various reasons, such as the incorrect data file, firmware upgrades, and other factors sometimes it is necessary to reprogram the chips. In case of offline programming, reworking is needed to desolder and solder the chip. |

No rework needed for data file changes and field upgrades. |

| Flexibility | Changeover time from one chip to a different chip is couple of minutes in case of automated programmer. User needs to install correct socket adapter and ready to go after loading project file. |

New programming algorithm development and testing might be involved when chip part number or PCB changes. Also there will be a need of designing new test fixture for different PCBs. |

| Reliability of product and quality | During programming, because the chip has to go in and out of the socket and feeder equipment, careles operation of automatic programming may result in chip pins deformation, resulting in degradation o soldering quality. So some of the aerospace, defense automotive electronics, medical electronics and othe high reliability requirement companies don't prefe offline programming. During programming, because the chip has to go in and out of the socket and feeder equipment, careless operation of automatic programming may result in chip pins deformation, resulting in degradation of soldering quality. So some of the aerospace, defense, automotive electronics, medical electronics and other high reliability requirement companies don't prefer offline programming. |

Programming is done after surface mounting so no such risks are involved. |