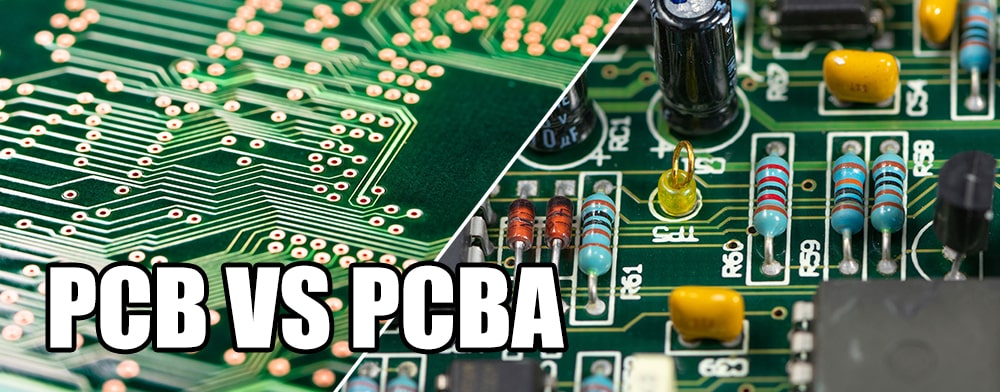

In the field of electronic manufacturing, two commonly used abbreviations are PCB and PCBA. These two terms are closely related and important for the electronic industry, but what do they mean and what is the difference between them?

What is PCB?

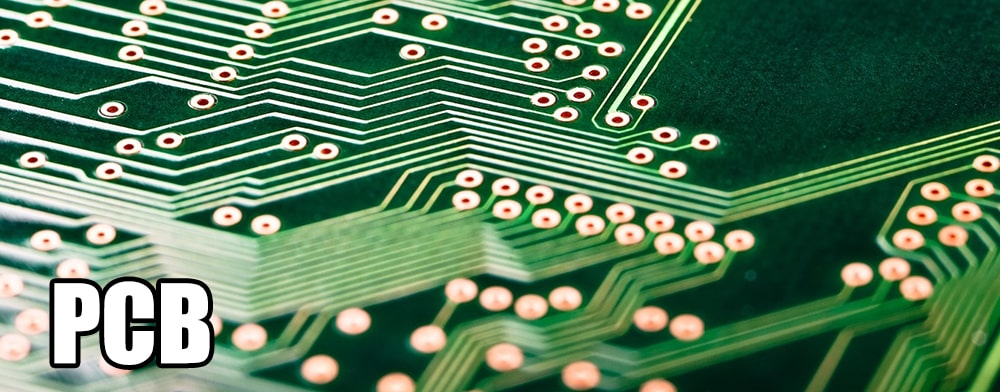

Printed Circuit Board (PCB) is the backbone of all major electronic products. It is a non-conductive material board with copper traces etched on it. These tracks connect different electronic components such as resistors, capacitors, and integrated circuits. PCB provides the physical foundation for designing and implementing electronic circuits.

PCB consists of multiple layers of copper traces and is made of various materials such as FR-4, polyimide, and aluminum. PCB manufacturing involves four stages:

1.Design: Engineers create a schematic that depicts the desired circuit layout.

2.Circuit board layout: Designers use specialized software to convert the schematic into a circuit board layout, specifying component placement, trace routing, and layer stacking.

3.Manufacturing: PCB is manufactured based on the circuit board layout. The substrate is prepared, the circuit pattern is printed, and excess copper is etched away using chemical solvents.

4.Inspection: The final stage is to test the circuit board for any defects or malfunctions to ensure its accuracy and functionality.

What is PCBA?

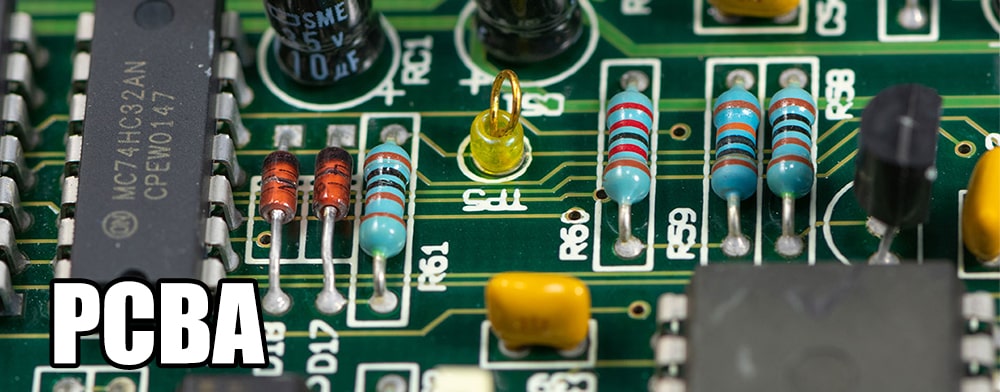

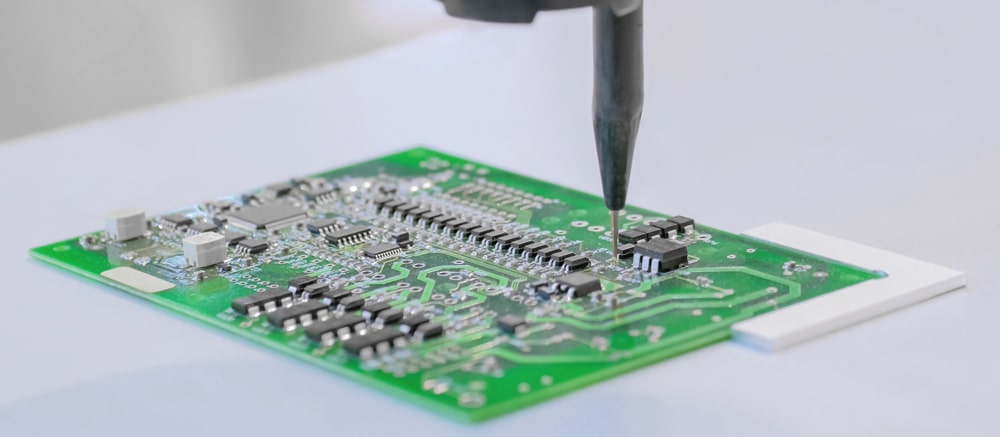

Printed Circuit Board Assembly (PCBA) refers to a PCB that has all electronic components fully assembled. PCBA is the final stage of the PCB manufacturing process.

In the PCBA process, various components such as resistors, capacitors, and ICs are soldered onto the board. The soldering process can be done using Surface Mount Technology (SMT), Through-Hole Technology (THT), or a combination of both. Once all necessary components are installed on the board, it undergoes functional testing. If the circuit board passes these tests, it can be integrated into the final electronic product.

The PCBA manufacturing process includes the following steps:

1.Component procurement: Manufacturers purchase the required electronic components such as resistors, capacitors, ICs, and connectors.

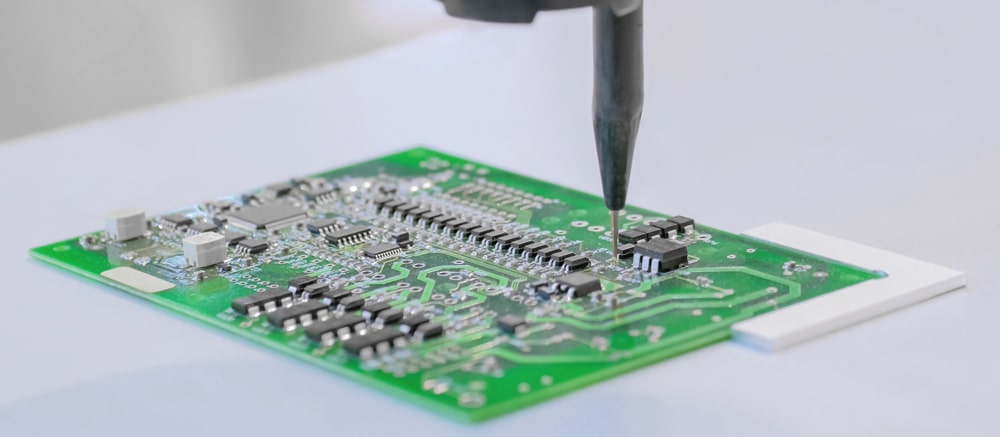

2.Solder paste application: A thin layer of solder paste is applied to the board where the components will be placed.

3.Component placement: Components are precisely placed in the designated locations using a pick and place machine.

4.Soldering: Components are soldered onto the board using reflow or wave soldering methods depending on their compatibility.

5.Inspection: Advanced testing methods such as Automated Optical Inspection (AOI) and X-ray inspection are used to verify the quality and functionality of the assembled board.

The main difference between PCB and PCBA

PCB refers to a bare board with copper traces, while PCBA refers to a PCB that has been populated with electronic components.PCB manufacturing involves designing and creating the circuit board layout but does not include component placement. In contrast, PCBA involves not only creating the PCB but also placing and soldering all necessary components onto the board.

PCB itself does not have functionality, it only provides the structure for the components. PCBA is a complete functional unit that can be directly integrated into electronic devices. It includes not only the PCB but also all the components necessary for the circuit board to function.

Conclusion

PCB is the foundation, providing the physical structure for designing electronic circuits. However, without components, PCB is just a board with copper traces. PCBA is a fully functional circuit board that can be integrated into electronic devices. By understanding these differences, businesses can better communicate their needs and ensure that their electronic products are designed and assembled correctly.

If you have any PCB or PCBA manufacturing needs, please feel free to contact us. POE has more than 20 years of experience in the PCB and PCBA fields and can help you solve any problems. Contact us to learn more!