PCB Contract Manufacturing

Contract manufacturing services are very necessary for companies that need to improve quality, reduce costs and do not need to manage complex production processes themselves. Contract manufacturers are able to contract all aspects from design verification to complete product assembly, saving customers unnecessary troubles, communication, etc., and can concentrate on product research and development and innovation.

Comprehensive PCB contract manufacturing services include:

1. VIP personalized service

Each project is unique, from initial consultation to final delivery, tailored solutions provide flexibility and a customer-centric approach to help customers realize their projects.

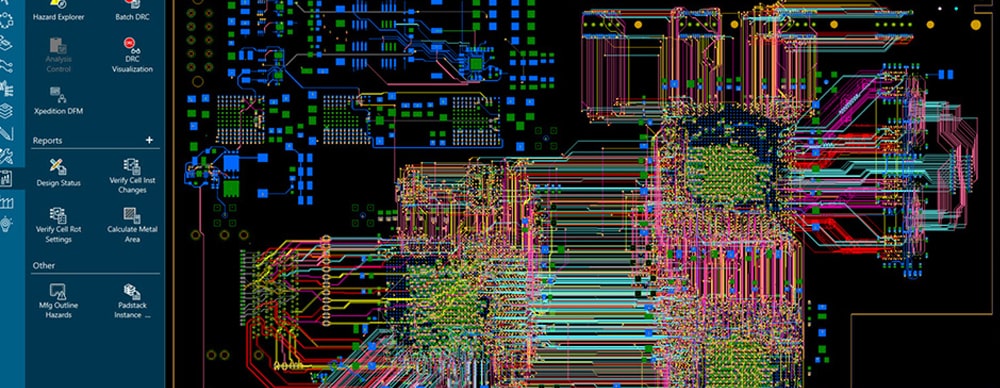

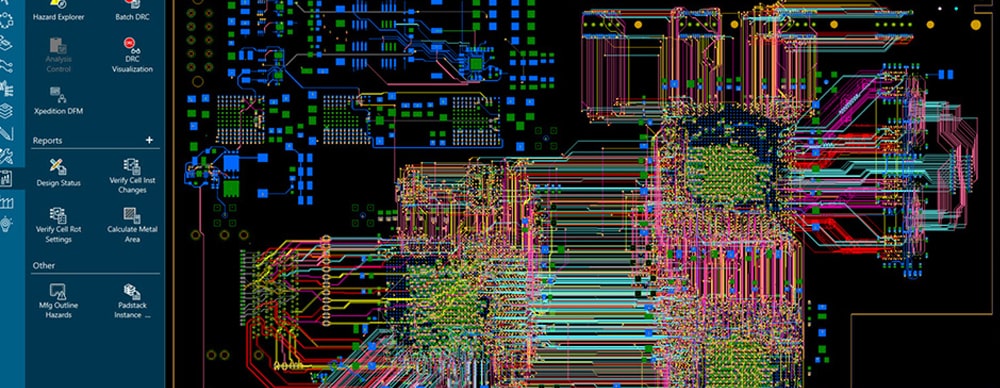

2. DFM review

DFM review allows PCB design to be optimized for manufacturability. DFM identifies potential problems in the design and reduces production risks.

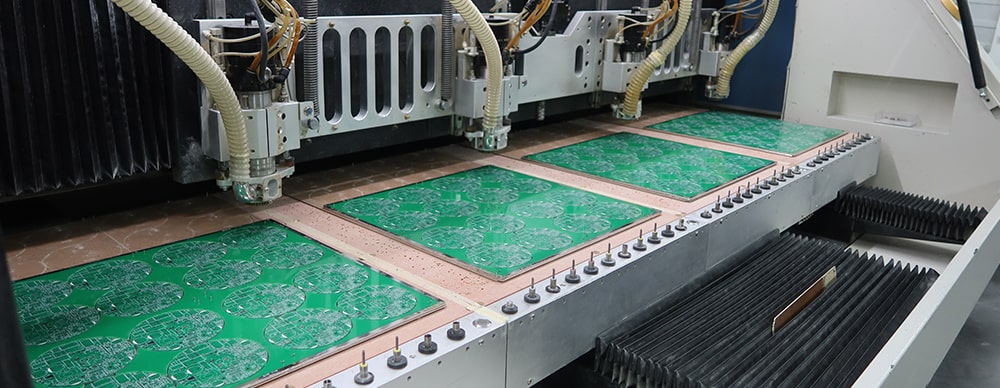

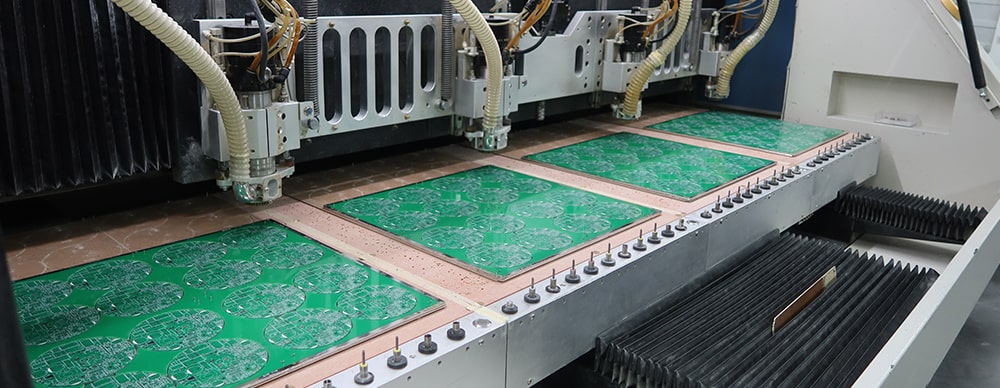

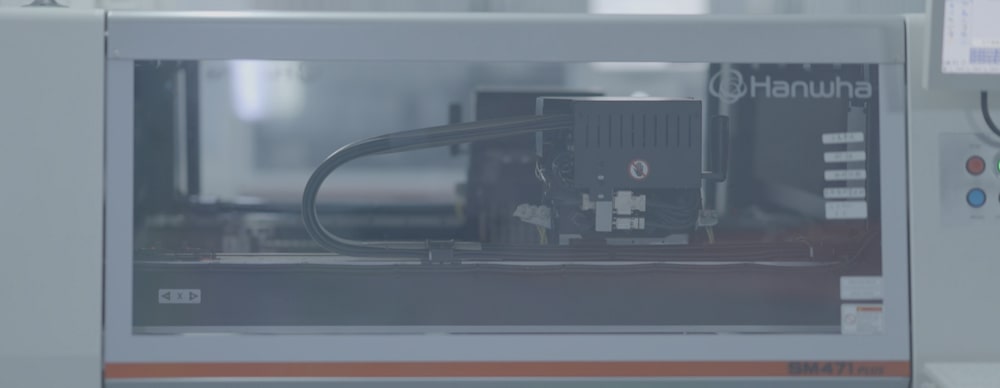

3. PCB manufacturing

PCB manufacturing includes the creation of layer stacking, drilling, electroplating, circuit etching and surface treatment. Cutting-edge technology is used to produce high-quality PCBs that meet industry standards.

4. Component procurement

Procurement of suitable components is indispensable for a complete PCB. Professional contract manufacturers can work with trusted component suppliers for a long time, thus obtaining better quality and price, and customers do not have to worry about the problem of being unable to communicate with suppliers from different countries.

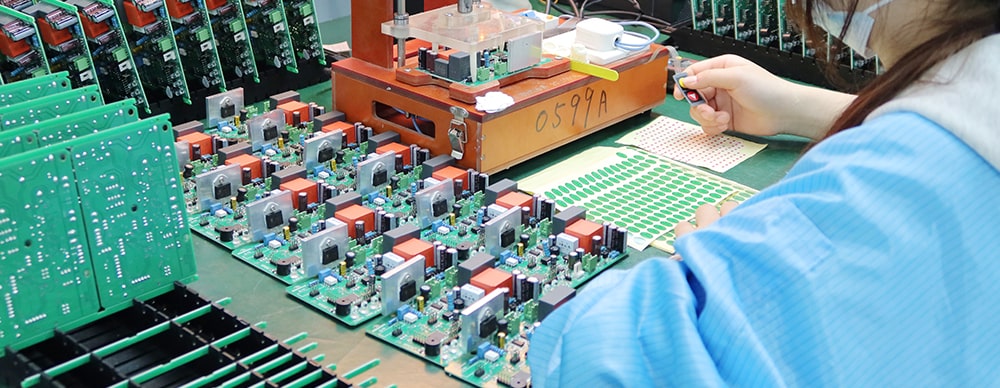

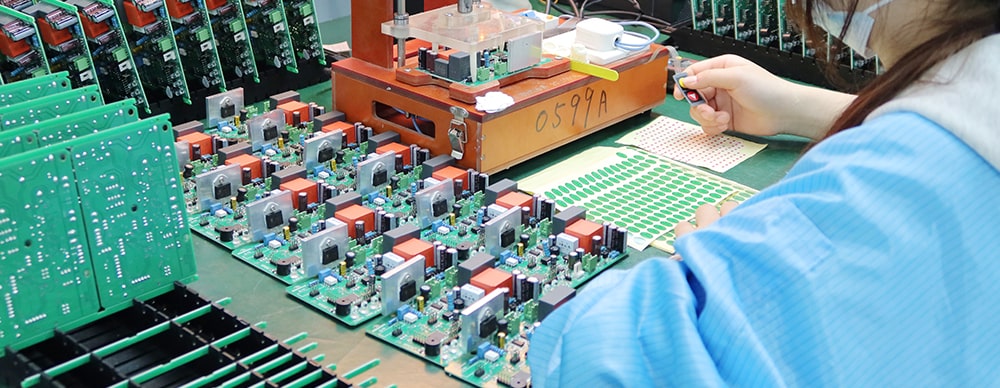

5. PCB assembly

PCB assembly includes the entire process from PCB production to component procurement, assembly and testing. The integrated solution simplifies the supply chain management of the entire PCB manufacturing and assembly.

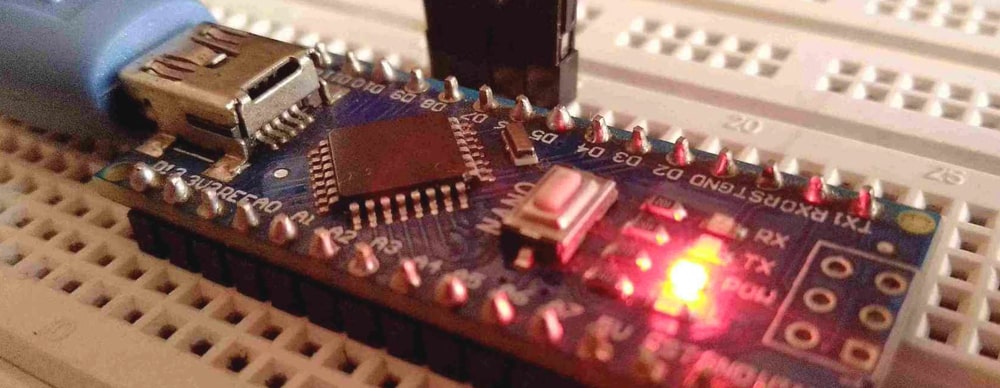

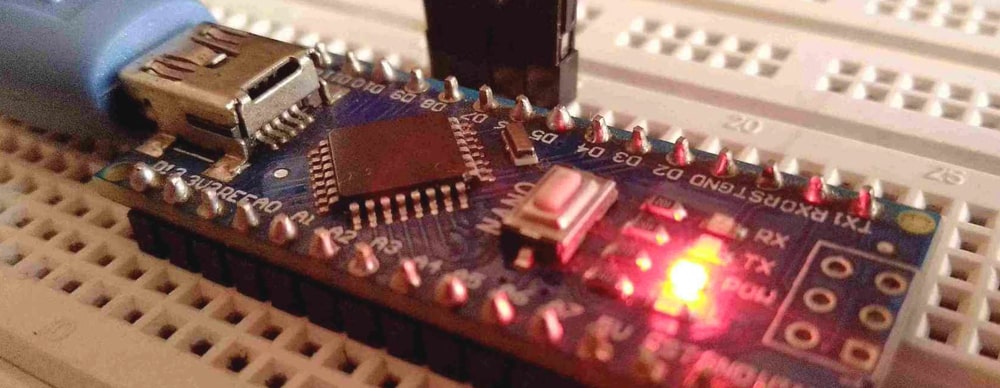

6. IC programming

IC programming is to preload firmware or software onto the IC before assembly to ensure that your PCB is functioning properly when delivered.

7. Functional testing

Functional testing is used to verify whether the PCB operates as designed under actual conditions. It ensures that all components work seamlessly and the final product meets performance expectations.

8. Quality assurance

Use rigorous testing methods, automatic optical inspection (AOI), in-circuit testing (ICT) and X-ray inspection to detect and resolve defects. Ensure that each PCB meets the highest quality standards.

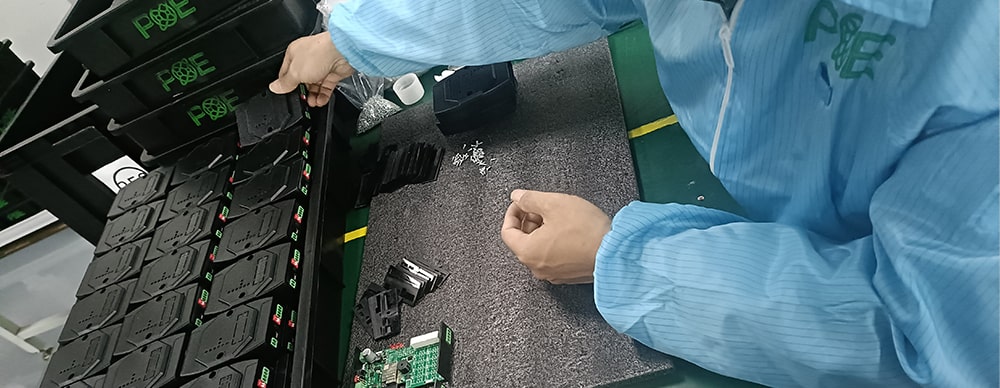

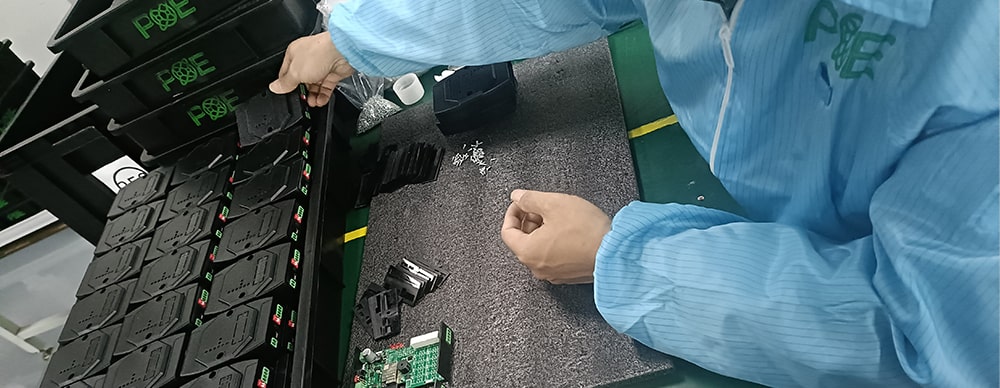

9. Shell assembly and box assembly

After the above links are completed, shell assembly and box assembly services can also be provided to make the product the final form.

10. Carton and Foam Services

Pack all components and assembled products into kits. Custom cartons and foam packaging protect the products during transportation and ensure they arrive intact.

11. Logistics

Logistics services are responsible for delivering your PCBs to their destination safely and on time. Includes: international transportation, export documents, customs clearance, delivery arrangements, tracking services.

The above are all the services included in PCB contract manufacturing. For companies that need to improve quality, reduce costs and do not want to manage complex production processes on their own, choosing a good PCB contract manufacturer is a very correct choice.

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China