|

Problem description:The ink stains on the legend on the fingerboard surface have not been cleaned off. Acceptance criteria: Not accepted |

|

Problem description: There is excess ink Acceptance criteria: It is acceptable if it does not affect identification |

|

Problem description:There is excess ink Acceptance criteria: It is acceptable if it does not affect identification |

|

Problem description: Legends with overlap Acceptance criteria: It is acceptable if it does not affect identification |

|

Problem description:Legend damaged Acceptance criteria: It is acceptable if it does not affect identification |

|

Problem description: The legend is incomplete. Acceptance criteria: It is acceptable if it does not affect identification |

|

Problem description: Marking ink is printed on the lead tin/gold surface Acceptance criteria: 1. The width of the pad/tin surface meets the requirements; 2. In the case of non-character overall graphic displacement, defects of 5% or 0.05MM position on the edge of the square pad are allowed. If the customer has requirements, it is not allowed; 3. BGA pad/SMT pad/IC position and button position are not allowed. |

|

Problem description: Marking ink is printed on the lead tin/gold surface Acceptance criteria: 1. The width of the pad/tin surface meets the requirements; 2. In the case of non-character overall graphic displacement, defects of 5% or 0.05MM position on the edge of the square pad are allowed. If the customer has requirements, it is not allowed; 3. BGA pad/SMT pad/IC position and button position are not allowed. |

|

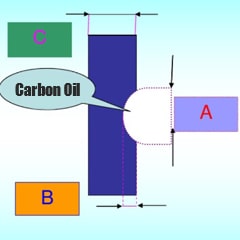

Problem description:Incorrect carbon oil coverage. Acceptance criteria: 1. B must be < 20% of the width C, and A must be < the width C; 2. Each carbon oil PAD can only have one gap, and copper exposure is not allowed; 3. When the carbon oil PAD width C>0.9MM, A is controlled to be less than or equal to (C+0.1MM)/2 of the carbon oil PAD. |

|

Problem description:Improper carbon oil coverage results in copper exposure. Acceptance criteria: 1. The gap width must be < 20% of the carbon oil width, and the gap length must be < the carbon oil width; 2. Each carbon oil PAD can only have one gap, and copper exposure is not allowed; 3. When the carbon oil PAD width is > 0.9MM, the gap length is controlled to be less than or equal to (carbon oil width + 0.1MM)/2 of the carbon oil PAD. |

|

Problem description:Ink bleeds from the edges of carbon ink graphics. Acceptance criteria:Does not affect the minimum spacing of 20%. |

|

Problem description:The pattern deviates from the specified position when screen printing carbon ink. Acceptance criteria:If there is only a slight printing deviation, it is acceptable as long as the entire row of PADs deviates in the same direction and ensures that the PAD is ≥0.1MM. |

|

Problem description: The blue glue failed to cover the required location. Acceptance criteria: Not accepted |

|

Problem description: Blue gel screen printing into unspecified VCUT slots or masked holes. Acceptance criteria: Not accepted |

|

Problem description: The blue glue fell off. Acceptance criteria: Not accepted |