Complete electronics manufacturing from PCB fabrication to final assembly. We manage your entire production process with full compliance and traceability. We don't just make boards, we build your product.

EMS (Electronics Manufacturing Services) providers handle the complete production of electronic assemblies. We manage PCB fabrication, component procurement, assembly, testing, and logistics - allowing you to focus on product development and market growth.

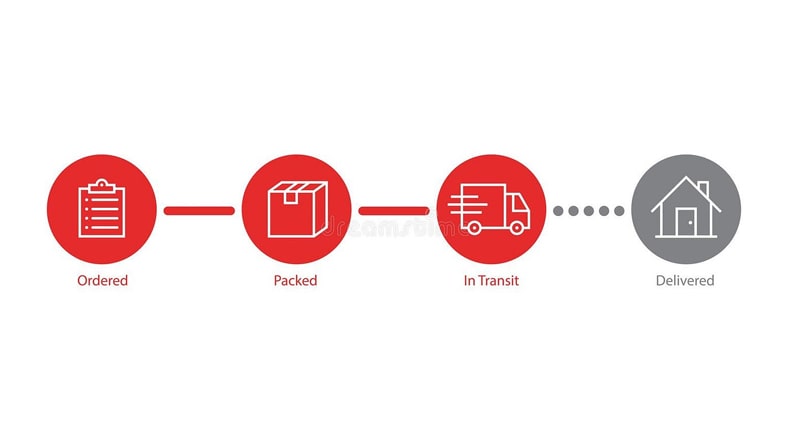

As your EMS partner, we take responsibility for the entire manufacturing process. You provide design files and specifications, we deliver tested, compliant products ready for deployment - with full documentation and traceability at every stage.

Manage PCB suppliers → Procure components from multiple distributors → Coordinate assembly facilities → Handle quality control and logistics independently

High overhead, fragmented processes, resource-intensive

Provide design files → We manage procurement, fabrication, assembly → Receive tested, certified products

Reduced costs, faster time-to-market, scalable capacity

SMT, THT, mixed technology, BGA, micro-BGA, 0201 components, press-fit connectors

Rigid, flexible, rigid-flex, HDI, multilayer up to 40 layers, heavy copper, RF/microwave

Industrial automation, PLC controllers, sensor modules and other industrial-grade applications

In-vehicle entertainment systems, ECU controllers, automotive sensors, etc.

Medical monitoring equipment, diagnostic instruments, portable medical devices

Routers, switches, base station equipment, IoT modules

Smart home devices, wearable devices, consumer electronic products

Test and measurement equipment, scientific instruments, precision control systems