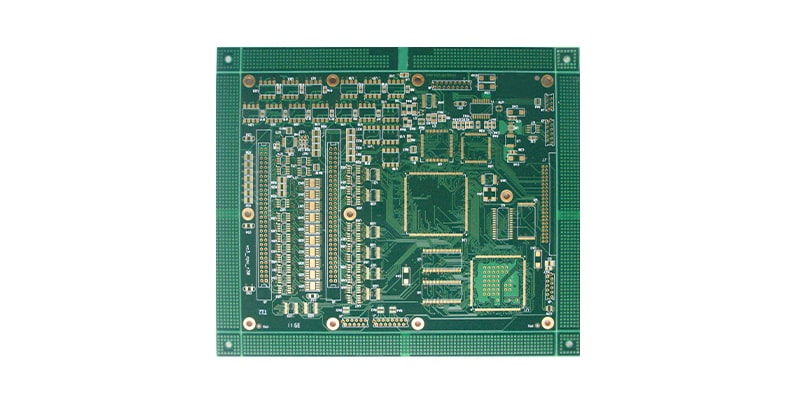

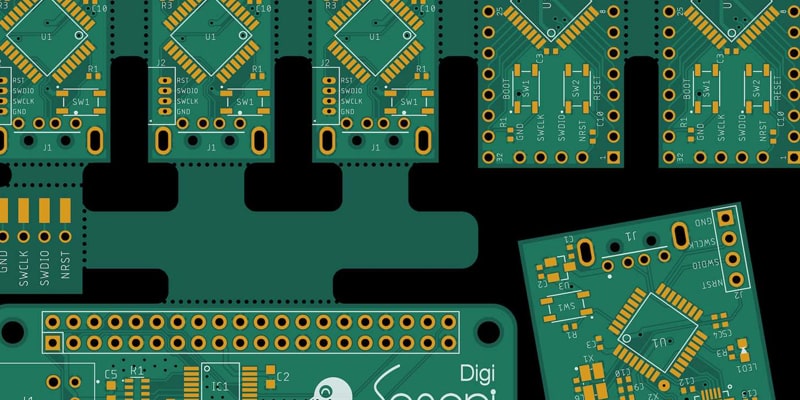

Advanced PCB fabrication from prototype to mass production

Single to 40-layer PCB manufacturing capability

Flexible thickness range for various applications

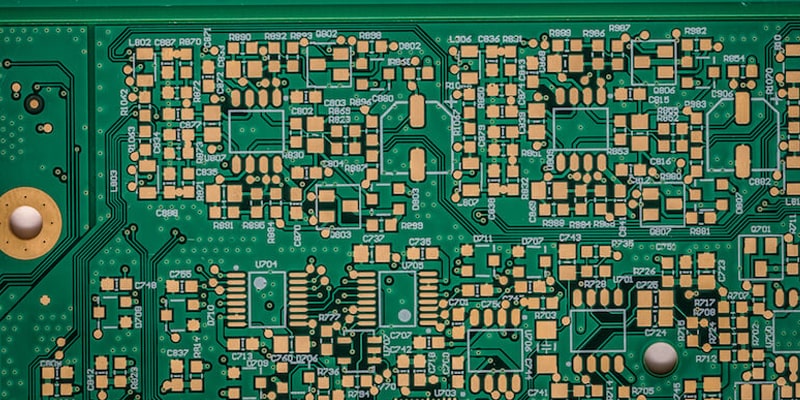

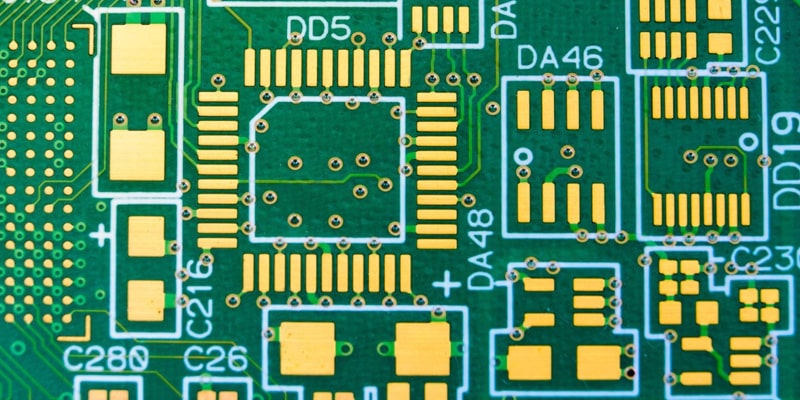

Ultra-fine trace capability for HDI designs

Micro via technology for high-density interconnect

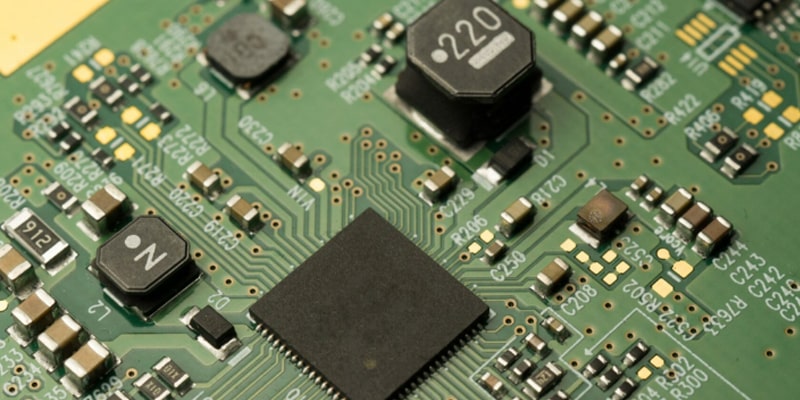

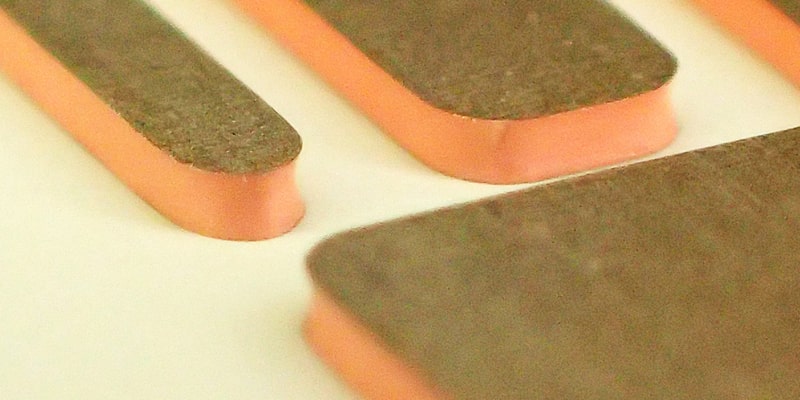

Standard to heavy copper for power applications

Multiple surface finish options available

High precision manufacturing tolerance

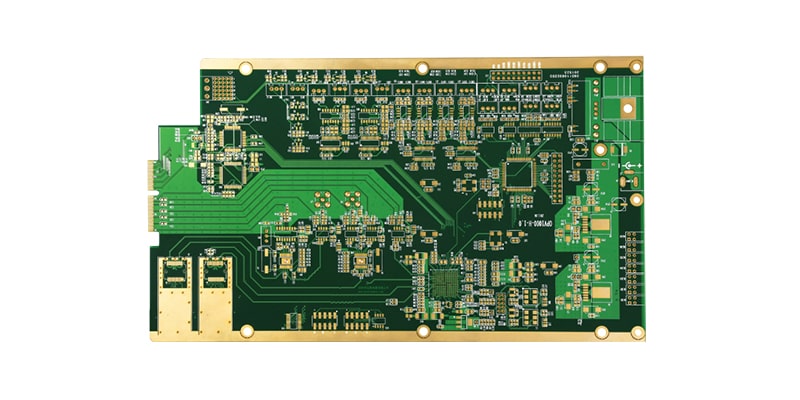

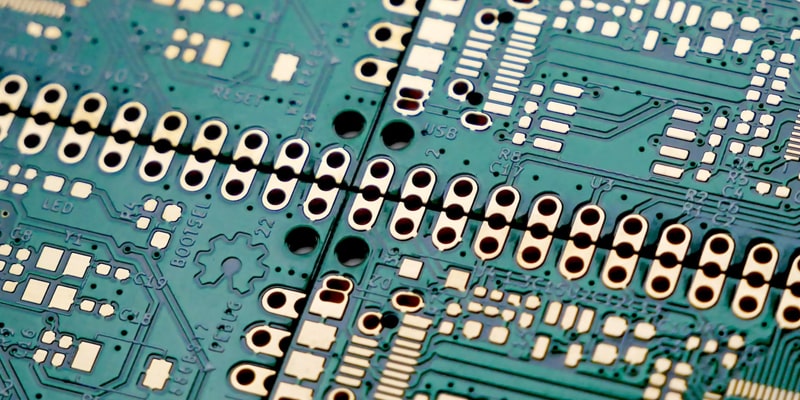

Large format PCB manufacturing capability

Fast prototype to production turnaround

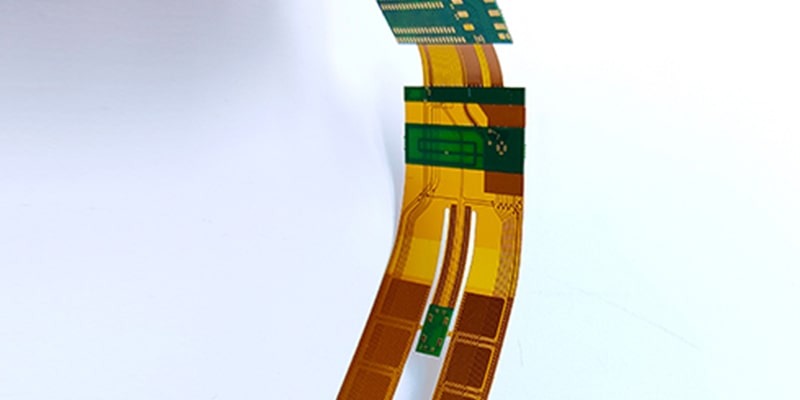

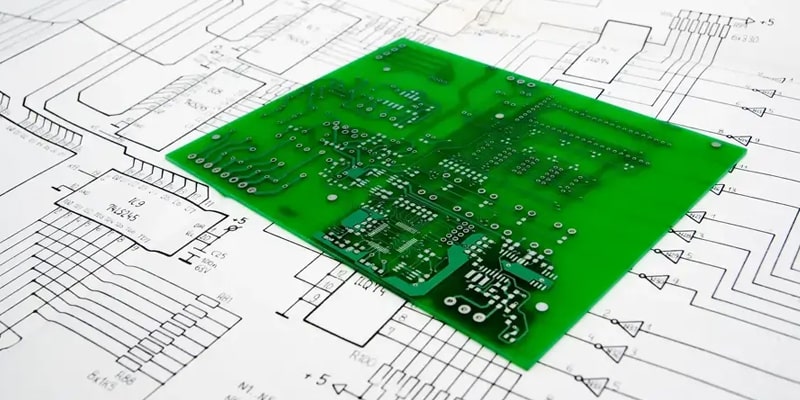

Our state-of-the-art PCB manufacturing facility spans 15,000 square meters with advanced production lines capable of producing single-layer to 40-layer PCBs. Equipped with the latest HDI technology, multilayer lamination systems, and precision drilling equipment, we serve industries requiring the highest quality standards. Our PCB manufacturing capabilities include rigid PCBs, flexible PCBs, rigid-flex combinations, and specialty materials like Rogers, Polyimide, and ceramic substrates for high-frequency and high-temperature applications.

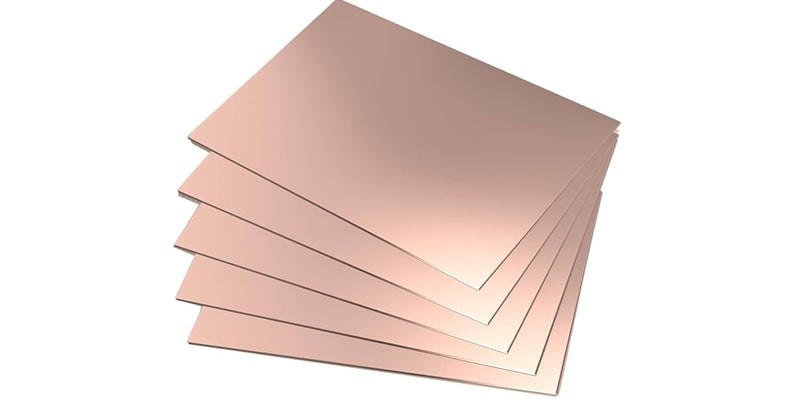

Premium FR4 substrate preparation and cutting

UV lithography for inner layer patterning

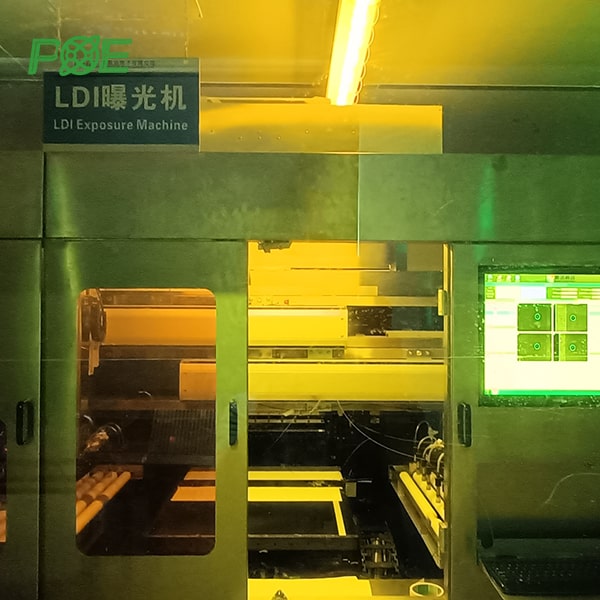

Photoresist application and exposure process

Chemical removal of unwanted copper traces

Automated optical verification of inner circuits

Oxide treatment for layer adhesion

Multi-layer PCB pressing and bonding

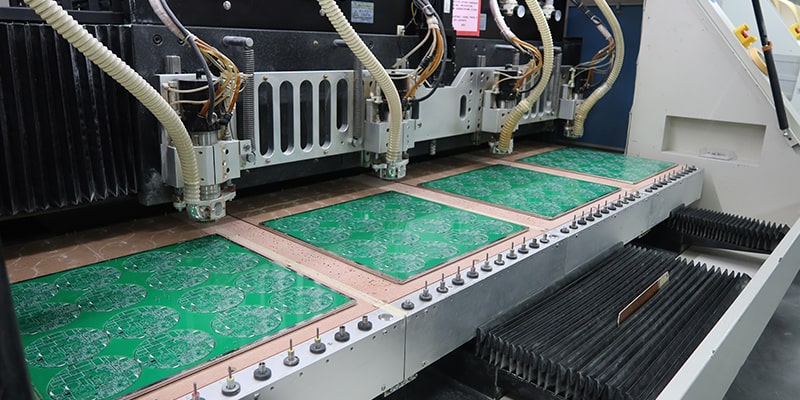

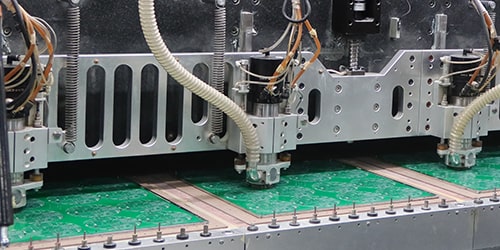

High-precision via and mounting hole drilling

Photoresist removal after processing

Plated through-hole copper deposition

External layer photoresist patterning

Electroplating copper in drilled holes

Final copper trace definition and cleaning

Final circuit pattern verification

X-ray inspection of internal connections

Protective coating application and curing

Component legends and marking printing

Moisture-free protective packaging

Rogers and PTFE materials for RF applications

Aluminum and copper core for thermal management

Advanced via-in-pad technology for BGA designs

Complex via structures for high-density designs

Precise impedance matching for high-speed signals

PCBs optimized for automated assembly

State-of-the-art PCB manufacturing equipment and processes

24H prototype, 3-5 days production, express options available

IPC Class 2/3, ISO9001, UL certified manufacturing

DFM analysis and PCB layout optimization services

Outstanding PCB quality and precision. Their HDI technology perfectly met our miniaturization requirements.

Excellent rigid-flex PCB manufacturing. Fast turnaround and superior quality for our wearable devices.

Reliable PCB partner for our automotive electronics. Consistent quality and on-time delivery.

Machines build speed.

— POE PCB/PCBA Manufacturer (@poe_pcba) October 29, 2025

People build trust.

What you see here is both — working in sync to make reliability repeatable.#POE #PCBA #ElectronicsManufacturing #Teamwork pic.twitter.com/0bEtxFOS3N

Since 1996, POE has become a globally renowned PCB company, providing small to medium volume PCB/ PCBA manufacturing services.