What is the role of solder mask in PCB?

12 December 2025

Views: 587

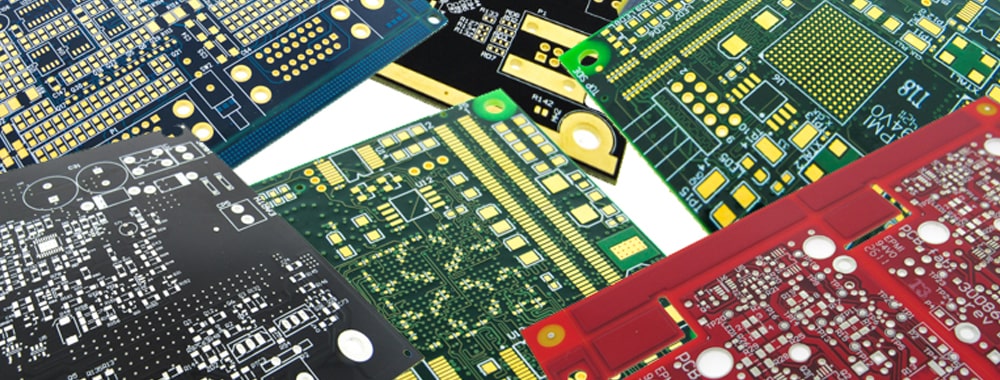

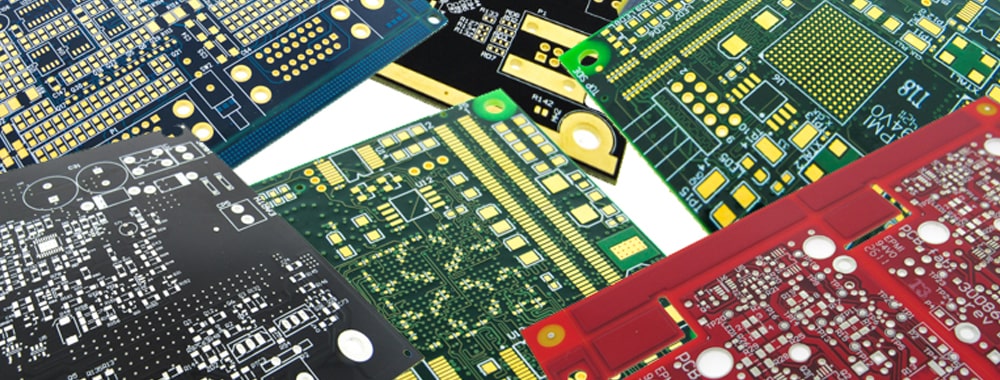

Solder mask, also known as solder resist, determines the color of PCB. The most common color is green, but blue, red and black are also widely used. Solder mask is a protective layer used on the surface of PCB. It is a polymer-based coating that covers the non-conductive areas of the circuit board while leaving certain areas (such as pads and vias) for soldering.

What is the role of solder mask in PCB?

1. Aesthetics and identification purposes

The solder mask gives the PCB its unique color, green, red, blue, black and white, among other colors. In addition to aesthetics, the solder mask also identifies components and traces during assembly, testing and maintenance.

2. Anti-oxidation protection

The main function of the solder mask is to protect the copper traces from oxidation and environmental factors. Copper naturally oxidizes when exposed to air, which affects its conductivity and solderability. The solder mask forms a protective barrier that prevents oxygen from contacting the copper, thereby maintaining the long-term reliability of the circuit board.

3. Solder control

During the soldering process, the solder mask helps control the flow direction of the solder. It prevents solder bridges from forming between closely spaced components and traces, thus avoiding short circuits. Solder mask creates specific areas (pads) where components can be soldered, ensuring precise and reliable connections.

4. Electrical Insulation

Solder mask acts as an electrical insulator to prevent accidental shorts between traces. This insulation is especially important in high-density designs where traces are closely spaced. Typical dielectric strengths for solder mask are 40-100 volts per micron.

5. Moisture Resistance

Solder mask has excellent moisture resistance, protecting the PCB from moisture and other environmental conditions.

6. UV Protection

Many solder masks are UV resistant, protecting the board from degradation caused by UV exposure. This is especially important for PCBs used in outdoor applications or in direct sunlight.

There are two main types of solder mask

1. Liquid Photosensitive Solder Mask (LPSM): Applied in liquid form, cured using UV light, provides excellent resolution and coverage.

2. Dry Film Solder Mask: Applied in thin film form, processed similarly to photoresist, provides consistent thickness, but is generally more expensive.

Conclusion

The solder mask plays many roles, making the PCB more beautiful, protecting the circuit board from environmental damage, preventing soldering defects, enhancing electrical insulation and improving signal integrity.

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China