1.A Brief Introduction on Functional Testing.

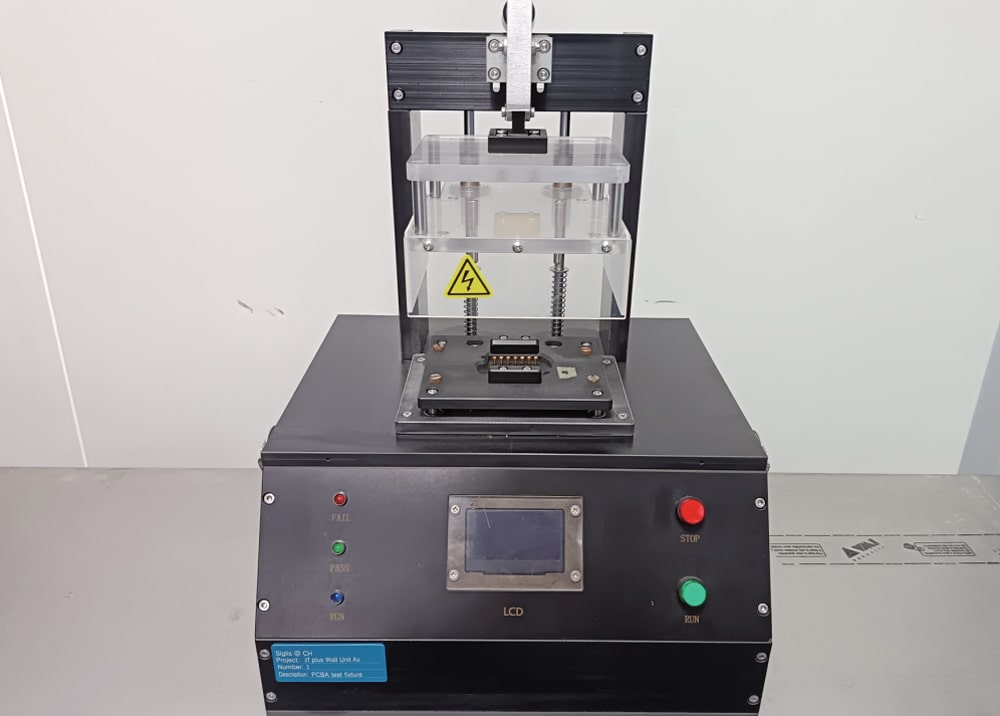

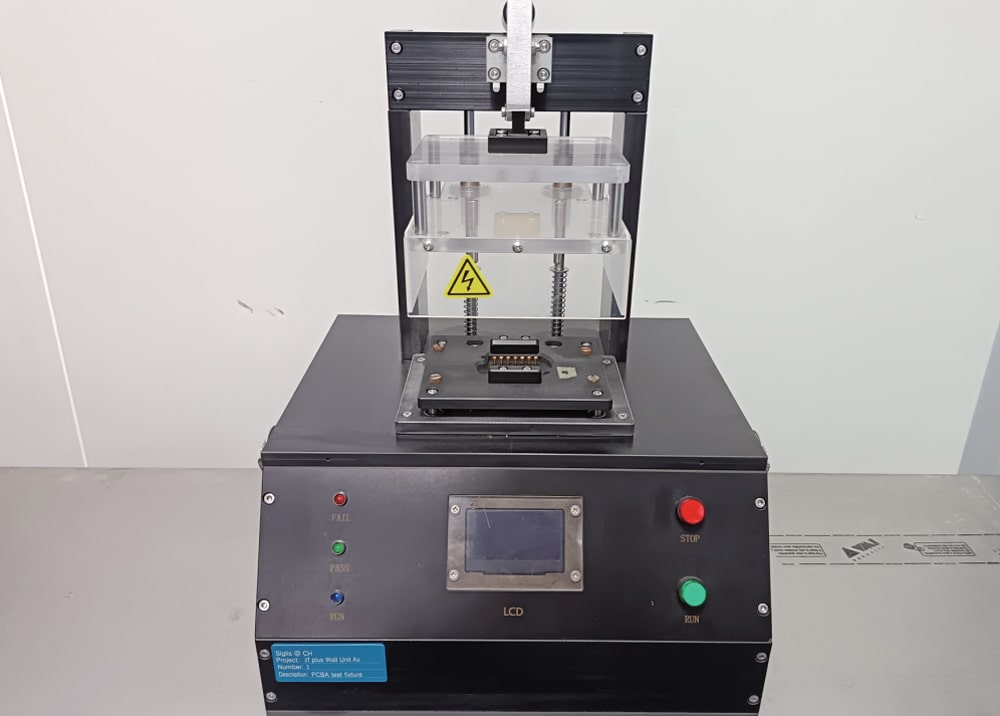

Functional testing is the final step of PCBA manufacturing to ensure zero-defect PCBs. At this stage, the design is already tested for, and hence the function of the PCB is checked at length and at various levels. The application environment is simulated; PCBs are connected to similar systems and the same final product. This technique is all about going as close as possible towards the real environment. This step gives the manufacturer a green signal to proceed with further processes. As the name implies, this technique verifies the functionality and behavior of the circuit boards to ensure their flawless performance. Functional testing is unique compared to other testing methods.

2.Why is Functional Testing Important?

Functional testing is important because without it, you may not accurately understand whether your application functions as intended. An application may pass non-functional tests and otherwise perform well, but if it doesn't deliver the key expected outputs to the end-user, the application cannot be considered working.

3.Common Problems Identified Through Testing.

Here is the list of some common problems that can be identified by performing functional testing of PCBs. So, let's have a look at them.

Power Integrity: This is one common problem in high-speed boards that run at fast edge rates. Some common power integrity issues are power rail collapse and ground bounce, excessive heat generation, and high AC impedance and/or DC resistance.The PCB functional test identifies factors that contribute to PDN resistance and impedance.

Inadequate Voltage/Current: In most cases, the circuit board fails or does not perform as expected due to inappropriate voltage or current supply. Sometimes, PCB components are subjected to more than normal voltage and subsequent overheating. In addition, the incorrect voltage could occur by placing components in the wrong places or missing them somewhere on the board. PCBA manufacturers analyze these problems via functional testing and take proactive steps accordingly.

Signal Distortion: Signal integrity issues in the circuit board can also affect its functionality. This signal distortion can occur due to various reasons such as crosstalk, impedance mismatch, and more. PCB functional test checks for excessive signal distortions, signal skew in buses, and other weird behavior in the circuit board that may affect its functionality.

Why is Functional Testing so Popular?

Functional testing is widely used by PCBA manufacturers and service providers owing to its following benefits.

A functional test detects any faulty or inappropriately placed components. It triggers root cause analysis for any type of fault in the circuit board.

Compared to other PCB test methods, functional testing is cost-effective and straightforward.

The individual can document the entire process. This, in turn, acts as a guideline for improving the overall quality.

This method tests the whole circuit board. So, there are zero chances of defects or errors.

Functional testing works in sync with other PCB testing methods, such as in-circuit and flying probe testing.

As mentioned, this testing allows the PCBA manufacturer to take the final call and approval from the client as well.

6.Commonly used flash file formats and programmers.

We accept bin. file and hex. file for programming. Here are some commonly used programmer:

|

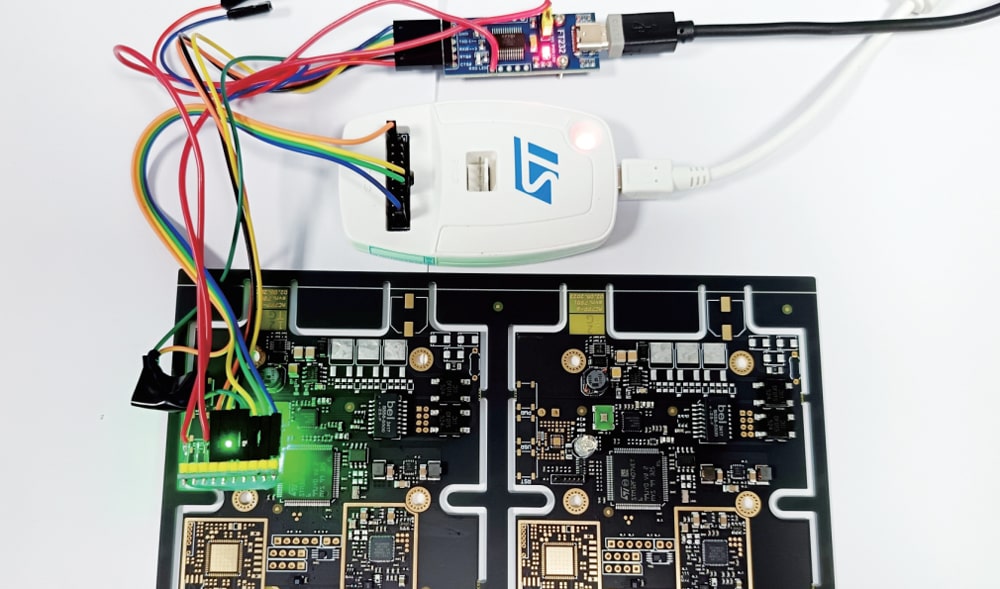

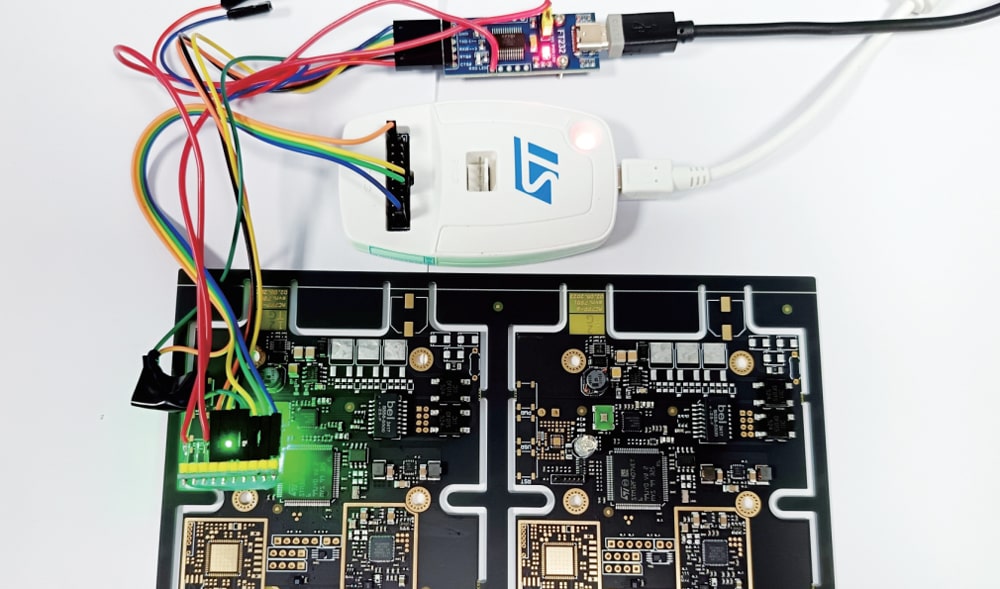

ST-Link: ST-Link is a programmer burner developed by STMicroelectronics. It is widely used in ST's microcontroller products, ST-Link has an easy-to-use interface and powerful features to support a variety of debugging and burning operations. (software:st-link utility) |

|

J-Link: J-Link is a more versatile programmer burner developed by SEGGER. It supports a variety of debugging interfaces, including JTAG, SWD and SWIM, etc., and is compatible with a variety of different types of microcontrollers and embedded chips. (software: J-Flash) |

|

Atmel: Atmel-ICE is Microchip's new powerful debug programming tool for the Atmel SAM and AVR® family of Atmel ARM® Cortex®-M chips. (Atmel Studio) |