|

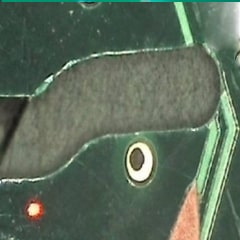

Problem description: When milling the board, the board is placed upside down or the board is tilted and the pins jump, resulting in milling damage. Acceptable standards: Not accepted |

|

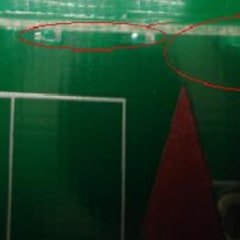

Problem description: Damage caused by improper operation by employees. Acceptable standards: 1.The circuit is not allowed to be deformed and open beyond the line filling standard; 2. The area cannot exceed the oil filling standard of 6.35mm*6.35mm. |

|

Problem description: Damage caused by improper operation by employees. Acceptable standards: Damaged nickel, or exposed copper. Not acceptable. |

|

Problem description: Wear marks on the machine rollers. Acceptable standards: Nickel exposed in the wheel marks and copper exposed on the plate surface. Not acceptable. |

|

Problem description: The V-CUT tool jumps and the machine screws are loose. Acceptable standards: Not accepted |

|

Problem description: V-CUT leaks or boards are mixed. Acceptable standards: Not accepted |

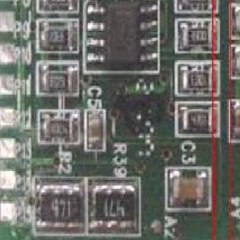

SMT line ready—then a $0.08 part stops it.

— POE PCB/PCBA Manufacturer (@poe_pcba) March 4, 2026

Wrong revs + "equivalents" + weak traceability = last-minute swaps, unstable lots, lost days.

POE locks AVL early + verifies incoming vs BOM/traceability.

DM “BOM” for a fast risk check. #PCBA #SupplyChain pic.twitter.com/CaNeV2FkTf

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China