|

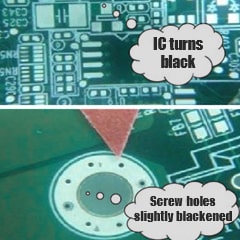

Problem Description: The silver layer is not deposited on the patch position, IC pad and BGA position where silver deposition is required. Acceptable standards: 1. Blackening of the patch position, IC pad and BGA position is not acceptable; 2. Slight blackening of the screw holes in the attached figure is acceptable. |

|

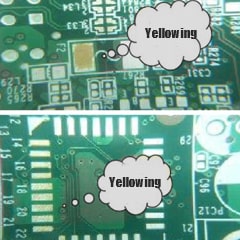

Problem Description: The PAD may appear black, gray, red, or yellow. Acceptable standards: Silver surface that turns yellow is not acceptable. |

|

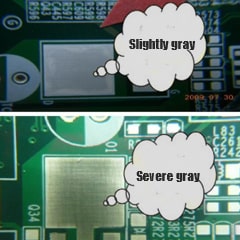

Problem Description: The silver surface is dark or partially white. Acceptable standards: 1. Slightly off-white is acceptable; 2. Severely off-white is not acceptable. |

|

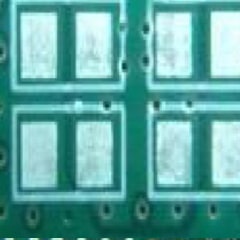

Problem Description: The silver layer is not deposited on the patch position, IC pad and BGA position where silver deposition is required. Acceptable standards: BGA position missing plating is not acceptable. |

|

Problem Description: The silver layer is not deposited on the patch position, IC pad and BGA position where silver deposition is required. Acceptable standards: Rough pads are not acceptable. |

|

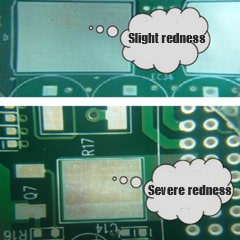

Problem Description: After silver immersion, the silver surface turns red, causing the thickness to fail to meet the MI requirements. Acceptable standards: 1. Slight redness is acceptable; 2. Severe redness is not acceptable. |

⚠ DIP can look perfect—and still build in risk. Most through-hole defects start at insertion, not solder.

— POE PCB/PCBA Manufacturer (@poe_pcba) January 29, 2026

If force, lead forming & hole-to-lead fit aren’t controlled: barrel/pad stress, marginal wetting, “NFF” intermittent returns.

DM “DIP” for our checklist. #ThroughHole pic.twitter.com/43kFK2qlHc

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China