|

Problem Description: Wrong color of gold. Accepted standards: Not accepted |

|

Problem Description: Failure to evenly cover Accepted standards: Not accepted |

|

Problem Description: The outer layer had dents before gold plating due to human manipulation. Accepted standards: 1. No dents larger than 0.125 mm are allowed in important areas; 2. No dents larger than 0.25 mm are allowed in non-important areas. |

|

Problem Description: 1. The gold surface is contaminated; 2. Insufficient maintenance; 3. The storage time exceeds the time specified in the document. Accepted standards: Not accepted |

|

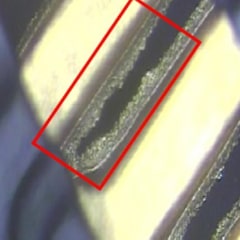

Problem Description: 1. The copper surface debris was not cleaned up during pre-treatment; 2. The nickel cylinder was not activated well. Accepted standards: Not accepted |

|

Problem Description: 1. Abnormal gold sinking parameters; 2. High concentration and high temperature of the chemical solution; 3. High nickel-gold content; 4. Staying in the tank for too long. Accepted standards: It is acceptable within the range of ±20% of the original spacing, or not exceeding 0.05mm (the smaller of the two). |

SMT line ready—then a $0.08 part stops it.

— POE PCB/PCBA Manufacturer (@poe_pcba) March 4, 2026

Wrong revs + "equivalents" + weak traceability = last-minute swaps, unstable lots, lost days.

POE locks AVL early + verifies incoming vs BOM/traceability.

DM “BOM” for a fast risk check. #PCBA #SupplyChain pic.twitter.com/CaNeV2FkTf

Email: all@poe-pcba.com

Email: all@poe-pcba.com

Whatsapp: 85292069596

Whatsapp: 85292069596

Tel: 0755-25312250/ +8613798543496

Tel: 0755-25312250/ +8613798543496

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China

Factory Address: Floor 3, Jinyuan Industrial Park, No. 56, Tangtou Avenue, Shiyan Town, Baoan District, Shenzhen China